Line blind valve (eyeglass valve) is a kind of gate valve that cuts off gas medium manually, electrically or pneumatically or hydraulically. It is generally divided into electric blind valve, hydraulic blind valve, closed plug valve and electric open blind valve.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationProduct Description

Line blind valve is widely used in the gas medium management system of industrial and mining enterprises, municipal, environmental protection and other industries, especially for cutting off harmful, toxic and flammable gases. Line blind valve is also suitable to be used as the blind plate of the pipe terminal to shorten the maintenance time or facilitate the connection of the new pipeline system.

Features

1. Novel structure, light weight, small size, convenient operation, rapid action and reliable performance;

2. Absolute positive shut-off, no spreading of pipe required, seal unaffected by piping misalignment.

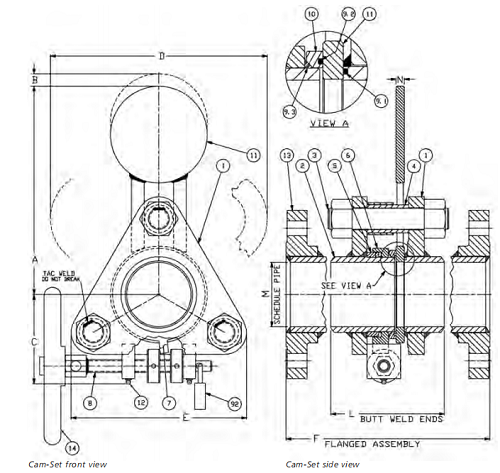

Technical Drawing

Line Blind Valves Specifications

|

Description |

Standard |

|

Size |

DN 15 (1/2") to DN 1200 (48") |

|

Pressure class |

ASME 150#, 300#, 600# |

|

Body material |

|

|

Spectacle Plate |

Stainless steel |

|

Stem |

Stainless steel |

|

Bolting |

Alloy steel |

|

O-Rings |

Viton, Buna-N |

|

Temperature |

232°C / 450°F |

|

Pipe Connection |

BW /RF |

|

Certification |

ASME, DIN, ISO, PED |

Line Blind Valves Engineering Standards

|

ASME Standard |

Description |

|

B16.5 |

Pipe flanges and flanged fittings |

|

B16.34 |

Valves - flanged, threaded and welding end |

|

B31.1 |

Power piping |

|

ASTM F1020 |

Line Blind Valves for Marine Applications |

|

ASME B&PV Code |

Description (Boiler & Pressure Vessel Code) |

|

Section II |

Material |

|

Section VIII |

Rules for Construction of Pressure Vessels |

|

Section IX |

Welding and Brazing Qualifications |

|

API Standard |

Description |

|

ASME 16.48 |

Steel Line Blanks for Refining |

|

API 598 |

Valve inspection and testing |

|

API 2217 |

Guidelines for confined space work in the Petroleum Industry |

|

Others |

Description |

|

ISO 9001 |

Quality management system |

|

NACE MR0175 |

Sulfide stress cracking and stress corrosion |

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.