16" x 12" 600LB trunnion mounted ball valve is made according to API6D standard. The valve body is made of A105. It has the structural characteristics of split type, side mounted, fixed ball, reduced diameter. Its connection mode is RF. And it has pneumatic operation mode.

16" 150LB double eccentric butterfly valve twins are made according to API 609 standard. The valve body is made of ASTM A216 WCB. It has the structural characteristics of high performance and dual eccentricity. Two valves share one worm gear head. Its connection mode is wafer. And it has turbine operation mode.

1" 300LB steam trap valve is made according to GB/T22654-2008 standard. The valve body is made of LF2 CL1. It has the structural characteristics of thermodynamic type. Its connection mode is RF.

2" 300LB change over valve is made according to ASME B16.34 standard. The valve body is made of ASTM A216 WCB. It has the structural characteristics of plug cover, the overall internal material is F316L. Its connection mode is RF. And it has Handwheel operation mode.

12" 1500LB cast steel slab gate valve is made according to API 6D standard. The valve body is made of A216 WCB. It has the structural characteristics of body cover bolt, full flow, cleanable pipe, anti-fire design. Its connection mode is RTJ. And it has gearbox operation mode.

DN200 PN16 angle bellows sealed globe valve is made according to BS EN 13709 standard. The valve body is made of EN 10213 1.4408. It has the structural characteristics of body cover bolt, exposed pole bracket, angle type, bellow seal. Its connection mode is RF. And it has hand wheel operation mode.

DN300 PN63 ball valve is made according to API 6D standard. The valve body is made of ASTM A105. It has the structural characteristics of fixed ball, full bore, anti-fire, anti-static, and anti-flying valve stem. Its connection mode is EN1092-1 D. And it has worm wheel operation mode.

16" 900LB ball valve is made according to API 6D standard. The valve body is made of A350 LF2. It has the structural characteristics of fully welded, fixed ball and full bore. Its connection mode is BW. And it has turbine operation mode.

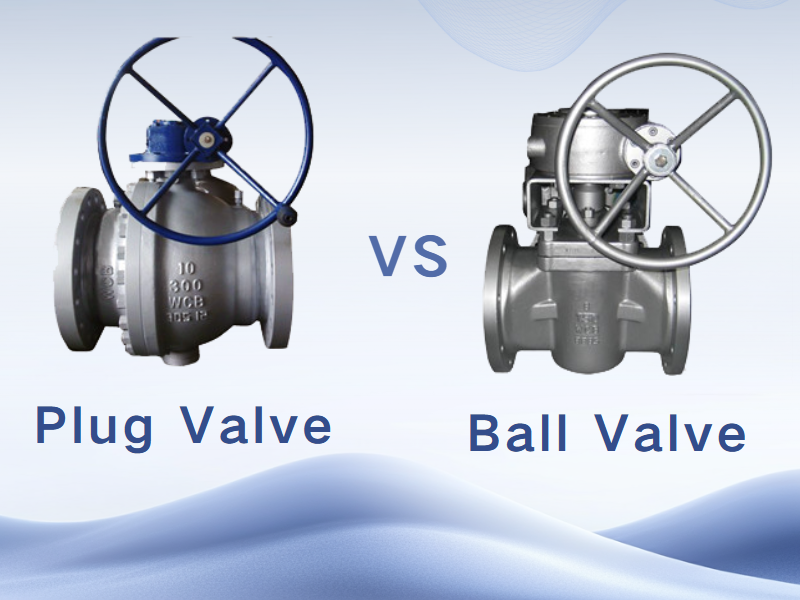

Ball valves and plug valves differ significantly in several aspects, including structure, operating principle, mode of operation, flow control capability, sealing performance, and application scenarios. These differences enable the two types of valves to perform distinct roles in their respective fields. Structural Differences The ball valve, a design evolved from the plug valve, utilizes a spherical element as its core component. By rotating the ball 90° around the stem axis, the valve can be opened or closed. Its structure is straightforward, consisting primarily of a spherical closure element with a through-bore housed within the valve body. In contrast, the structure of a plug valve is more complex. It comprises multiple components such as the valve body, bonnet, plug, seat, and stem. The closure element is a cylindrical or tapered plug that controls flow by rotating 90°, aligning or misaligning the port in the plug with the flow passage in the valve body to achieve opening or shutoff. Operating Principle The operating principle of a ball valve relies on the rotation of the ball to control the on-off flow of fluid. When the ball is in tight contact with the valve seat, the clearance between them is completely sealed, thereby preventing fluid leakage. When the ball rotates to a position disengaged from the seat, the fluid is allowed to flow freely through the passage inside the valve body. The operating principle of a plug valve differs in that it primarily controls the flow passage by rotating the plug element to open or close the valve. In a plug valve, the plug is connected to the stem and rotates together with it to achieve flow control. The closure element is a tapered plug with a port, and the flow passage is designed to be perpendicular to the axis of the plug. This configuration enables the plug valve to operate more efficiently and reliably during opening and closing. The operation of a ball valve is notably simple, requiring only a 90-degree rotation to achieve opening or closing. This design allows the flow passage to be opened or shut off quickly and smoothly when the ball is rotated by 90 degrees, providing both convenience and efficiency. In addition, ball valves offer relatively low flow resistance in the fully open or fully closed position, making them particularly suitable for applications that require rapid on-off operation. By contrast, the operation of a plug valve is comparatively more complex, as several turns are typically required to complete the opening or closing action. The valve plug is designed in a cylindrical or tapered form and regulates fluid flow through rotation. Nevertheless, plug valves demonstrate excellent performance in flow regulation, enabling precise adjustment of the flow passage diameter and accurate control of flow rate. However, due to the relatively complicated operating process, plug valves are not well suited for frequent operation...

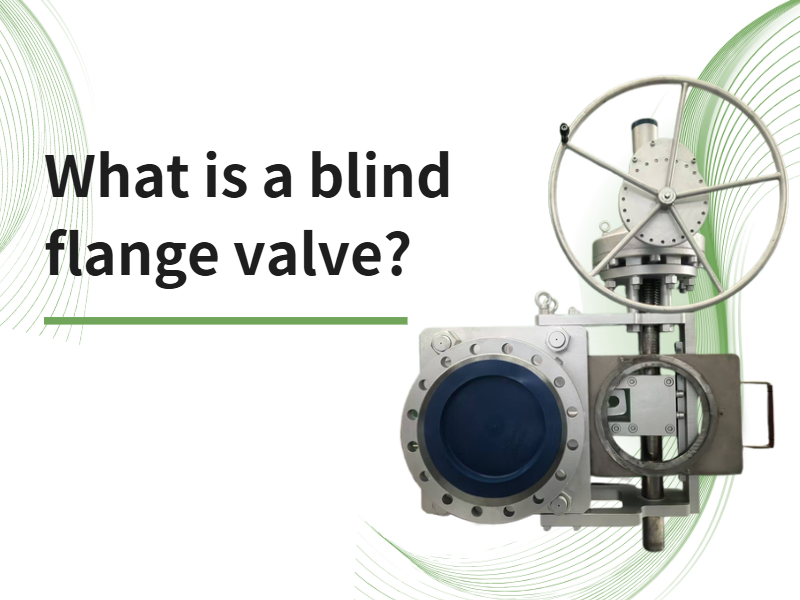

In industrial valve systems, a high-quality blind plate valve ensures safe and efficient operation of equipment. It is suitable for gas pipelines in metallurgy, chemical processing, petroleum, and municipal systems, serving as an effective device for positive gas isolation. Working Principle and Features The blind plate valve consists of left, center, and right valve bodies, a valve plate, shafts, a compensator, and two drive units (for clamping and travel respectively). The clamping mechanism uses a drive assembly to actuate a linkage system, enabling three lead screws to operate synchronously and press the valve bodies against the valve plate to achieve sealing. This design provides good synchronization and uniform sealing force distribution. Positioning rollers are installed along the outer lower edge of the valve plate to enhance sealing reliability and ensure overall stability and sealing accuracy during operation, thereby extending the service life of the valve. Valve Operating Sequence The clamping drive unit actuates the crank and linkage mechanism, causing the lead screws to rotate synchronously and retract the center body from the sealing surfaces (release condition). Guide wheels installed on the center body move laterally and simultaneously drive the valve plate. When the valve bodies are fully opened, the valve plate is positioned between the sealing faces of the left and right bodies, and the sealing surfaces are completely disengaged. The plate drive unit is then activated. Through a lever arm mechanism, the valve plate rotates, bringing the blind plate into the pipeline position. The clamping drive unit is started again to fully clamp the valve plate, completing valve closure. Valve Opening The clamping drive unit first fully releases the valve bodies. The turning drive unit then rotates the valve plate so that the through-port aligns with the pipeline. Finally, the clamping electric actuator presses the valve plate to complete the opening operation.

Wide-body ball valves and single-piece ball valves are both types of ball valves used for controlling the on/off flow of medium in pipelines. Both wide-body and single-piece ball valves feature a one-piece (integral) body design, unlike split-body designs. This differs from two-piece and three-piece ball valves, which have segmented valve bodies. For internally threaded wide-body ball valves, the valve body is made from round or hexagonal stock, using either bar material or forged components. The ball core features a reduced-diameter design and is inserted from one side of the valve body. The stem uses an internal anti-blowout structure. Flat surfaces are machined on both the inlet and outlet sides of the body to facilitate assembly of the ball valve and allow the use of wrenches during pipeline installation. In wide-body ball valves, the stem stuffing box is relatively shallow, and the internal packing volume is limited, resulting in a moderate sealing performance of the stem. Therefore, these valves are more suitable for low-pressure medium applications. In contrast, two-piece and three-piece ball valves feature stem stuffing box structures that provide reliable sealing for high-pressure medium applications. The structure of flanged wide-body ball valves is essentially the same as that of internally threaded wide-body ball valves. Typically, the flange is connected to the intermediate valve body via threaded fasteners, although some designs utilize a forged one-piece structure. Externally threaded wide-body ball valves can use a union-type structure, where the union is directly welded to the pipeline and connects to the external threads on the valve body. This design allows for easy disassembly and reassembly during valve maintenance or replacement without requiring separate unions on the pipeline. The valve bodies of single-piece internally threaded ball valves and single-piece flanged ball valves are manufactured using casting processes, with the ball core featuring a reduced-diameter design. The stem uses an internal anti-blowout structure. The inlet and outlet ends of single-piece internally threaded ball valves have a hexagonal shape, similar to conventional internally threaded valves, to facilitate wrench operation and secure installation. In single-piece flanged ball valves, the flange and valve body are cast as a single unit, eliminating the need to machine and assemble the flange separately as in wide-body flanged ball valves. This approach reduces cost and simplifies the manufacturing process. Single-piece wafer-style ball valves have a shorter valve body length, making them more suitable for pipelines with limited space. Wide-body and single-piece ball valves both use a reduced-diameter ball design, resulting in higher flow resistance compared with two-piece and three-piece ball valves. The main differences are as follows: Valve Body Manufacturing Process ● Wide-bo...

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

"Everything is perfectly made. We are grateful for the confidence you are showing in our organization and fully trust our hard-work will be fruitful for both of our companies. You are truly a GEM for Dervos Valves. Our best compliments to you!"

"Your customer service is outstanding. ... ... The check valves works fine and the customer service certainly makes up for it. ... ... The customer service couldn’t be better."

"We are very satisfied with all your kind business supports. You are always kindly answering all our questions. So, we thank you for all your efforts. When we have any new project, we will readily make a contact with you!"

"I’ve received your document today. Thank you so much. Our engineer says your report seems to have been done quite well, he appreciated, of course we haven’t got the vannes so we haven’t had a check, but I believe there won’t be problem, hope so."

"Thank you for engaging with our organisation regarding Dervos. We place various orders with Dervos and products were always completed ex-factory, to drawing and within the time periods indicated. Dervos is a very proud company and place huge emphasis in delivering quality products to their customers."