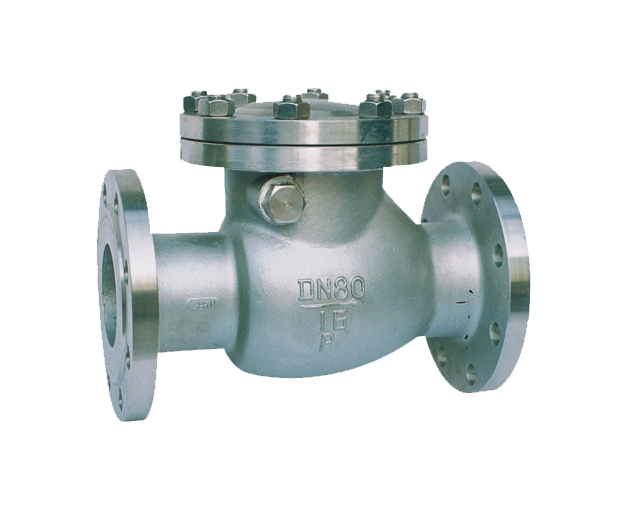

When installing flanged check valves, the following precautions

should be taken to ensure their proper operation and long-term use:

1. Preparation

before Installation

-

Inspect the

valve: Ensure that the valve has not been damaged during transportation and

that there are no foreign objects inside the valve body.

-

Clean the

pipeline: Clean debris such as weld slag and rust from

inside the pipeline to prevent them from entering the valve body.

-

Verify

parameters: Check the pressure, temperature, material, and other parameters on

the valve's nameplate to ensure they meet the requirements of the working

conditions.

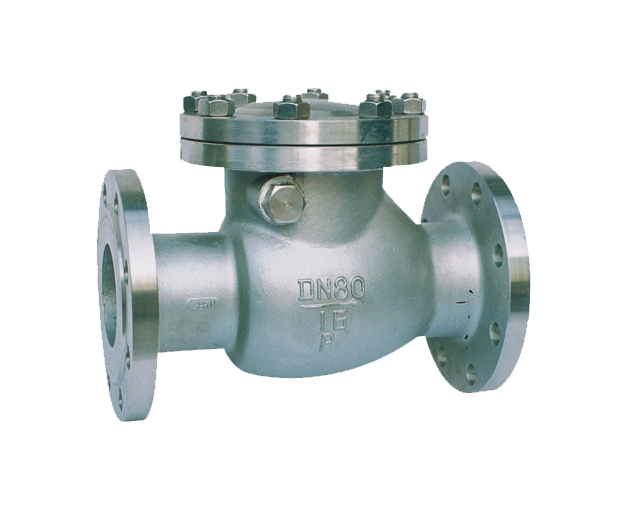

2. Installation

Position and Direction

-

Flow

direction marking: Ensure that the arrow marking on the valve is consistent

with the flow direction of the medium in the pipeline.

-

Vertical

installation: Check valves are typically installed vertically, with the valve

disc free to open and close. When installed horizontally, ensure that the valve

disc can move freely.

3. Flange

Connection

-

Align flanges:

Ensure that the flanges of the pipeline and valve are aligned to avoid offset or stress concentration.

-

Flange

gasket: Select the appropriate gasket material and place it correctly between

the flanges to prevent leakage.

-

Bolt

tightening: Tighten the flange bolts uniformly in a

diagonal sequence, gradually increasing the force to ensure uniform stress on

the flange and prevent deformation.

4. Avoid Stress

-

Pipeline

support: Install

appropriate supports before and after the valve to prevent the weight and

stress of the pipeline from concentrating on the valve.

-

Reduce

vibration: In pipeline systems with significant vibration, take measures to

reduce vibration transmission to the valve and extend its lifespan.

5. Testing and

Commissioning

-

Seal test:

Conduct hydrostatic or pneumatic testing after installation to check the

sealing performance of the flange connections and inside the valve.

-

Function

test: Confirm that the check valve can open and close normally during medium

flow and stoppage.

6. Regular

Maintenance

-

Regular

inspection: Regularly inspect the tightness and sealing performance of the

flange connections to prevent loosening and leakage.

-

Clean the

valve body: Clean the inside of the valve body when necessary to prevent debris

accumulation that could affect valve performance.

-

Lubricate

components: For check valves requiring lubrication, regularly inspect and add

lubricant to ensure flexible valve disc movement.

7. Special

Working Condition Considerations

-

High

temperature and pressure: In high-temperature and high-pressure conditions,

select appropriate gasket and bolt materials to prevent leakage caused by

thermal expansion and contraction or stress concentration.

-

Corrosive

media: For corrosive media, choose valves made of corrosion-resistant materials

and implement corrosion prevention measures.

8. Environmental

Requirements

-

Protective

measures: When installing in outdoor or corrosive environments, take protective

measures for the valve, such as applying anticorrosive paint or installing

protective covers.

-

Temperature

control: In extreme temperature environments, take insulation or cooling

measures to prevent the valve from failing due to temperature effects.