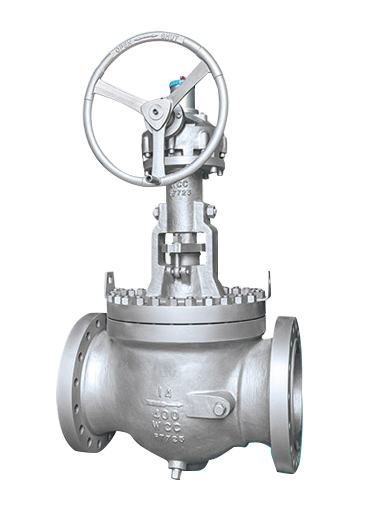

The Orbit Ball Valve, with its unique design and reliable performance, has been widely used in industrial fields such as oil, natural gas, and chemicals.

1. Structure of Orbit Ball Valve

The structure design of the Orbit Ball Valve differs from that of a conventional ball valve. Its main components include:

(1) Valve body: The body of the Orbit Ball Valve is typically made of forged or cast steel, offering high strength and corrosion resistance, and is capable of withstanding high-pressure and high-temperature environments.

(2) Ball: The ball moves within the valve body through a specially designed track and is usually made of stainless steel or nickel-based alloys, providing excellent wear and corrosion resistance.

(3) Seat: The seat is the part that comes into contact with the ball, typically made of metal to ensure sealing performance under high pressure and high temperature conditions.

(4) Stem: The stem connects the ball to the actuator, responsible for transmitting operational torque to move the ball within the valve body.

(5) Sealing System: This includes the seat seal and stem seal, ensuring no leakage of the medium. Seals are typically made of metal or high-performance polymer materials.

(6) Actuator: This includes manual operation mechanisms or automated actuators used to control the opening and closing of the valve.

2. Working Principle of Orbit Ball Valve

The working principle of an Orbit Ball Valve differs from that of a conventional ball valve, with its core function relying on the track movement and rotation of the ball within the valve body. The opening and closing process of an Orbit Ball Valve is as follows:

Closed State: In the closed state, the sealing surface of the ball is tightly pressed against the valve seat, forming a reliable seal and preventing the flow of the medium.

Opening Process:

(1) Initial Eccentric Movement: When the actuator applies operational torque, the ball first moves eccentrically up or down along the track, gradually disengaging from the valve seat. This process reduces friction between the ball and the seat, preventing wear on the sealing surface.

(2) Rotational Movement: After completing the eccentric movement, the ball continues to rotate 90 degrees, fully opening the passage and allowing the medium to flow smoothly through. As the ball's movement and rotation on the track occur in separate steps, the operation is smoother, and the required torque is lower.

Closing Process:

(1) Initial Rotational Movement: When the actuator operates in reverse, the ball first rotates 90 degrees to the closed position, thereby closing the passage.

(2) Eccentric Movement: After the ball completes the rotation, it moves along the track back to the valve seat, forming a seal. This frictionless sealing process ensures high sealing performance and a long service life for the Orbit Ball Valve.

3. Advantages of Orbit Ball Valve

(1) Frictionless Sealing: The eccentric and rotational movements of the Orbit Ball Valve are separated, which reduces friction between the sealing surfaces and extends the service life of the sealing components.

(2) Low Operating Torque: Due to reduced friction during the operation process, the Orbit Ball Valve requires a lower operating torque, facilitating both manual operation and automated control.

(3) High Sealing Performance: The metal-to-metal sealing design of the Orbit Ball Valve ensures excellent sealing performance even under high pressure, high temperature, and corrosive media conditions.

(4) Bidirectional Sealing: Orbit Ball Valves typically feature bidirectional sealing capability, providing reliable sealing in both directions and accommodating various installation and usage requirements.

(5) Wear and Corrosion Resistance: Orbit Ball Valves are constructed from high-quality materials, offering excellent wear resistance and corrosion resistance, making them suitable for harsh operating conditions.

4. Application of Orbit Ball Valve

1. Oil and Gas Industry: Suitable for high-pressure transport pipelines, wellhead equipment, and processing units, capable of withstanding high pressure and corrosive media.

2. Chemical Industry: Suitable for the transport and control of various chemical media, particularly excelling in high-temperature and highly corrosive environments.

3. Power Industry: Suitable for steam pipelines and cooling systems in power plants, capable of withstanding high temperatures and high-pressure conditions.

4. Other Industries: Orbit ball valves are also widely used in water treatment, paper manufacturing, metallurgy, and other industries, providing reliable fluid control solutions.