Line blind valve is a kind of gate valve that cuts off gas medium manually, electrically or pneumatically or hydraulically. It is generally divided into electric blind valve, hydraulic blind valve, closed plug valve and electric open blind valve.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationProduct Description

High temperature cam-slide is a special type of line blind valve, which differs significantly from the regular blind flange valve in its high-temperature resistance capability. Regular line blind valves are typically suitable for media with temperatures between 0°C and 200°C, while high temperature cam-slide line blind valve can withstand usage in high-temperature environments, usually suitable for situations where the temperature is above 200°C and can even withstand temperatures as high as 800°C.

Features

1. It is able to withstand the use in high temperature environments, typically suitable for applications with temperatures higher than 200℃, and can even withstand temperatures as high as 800℃.

2. It features a compact design, allowing it to be used in space-constrained environments.

3. The operation is simple and convenient, requiring only a handle to complete the switch.

4. The valve body is typically made of stainless steel or other corrosion-resistant materials, making it suitable for use in harsh chemical environments.

5. It has good sealing performance, effectively preventing medium leakage.

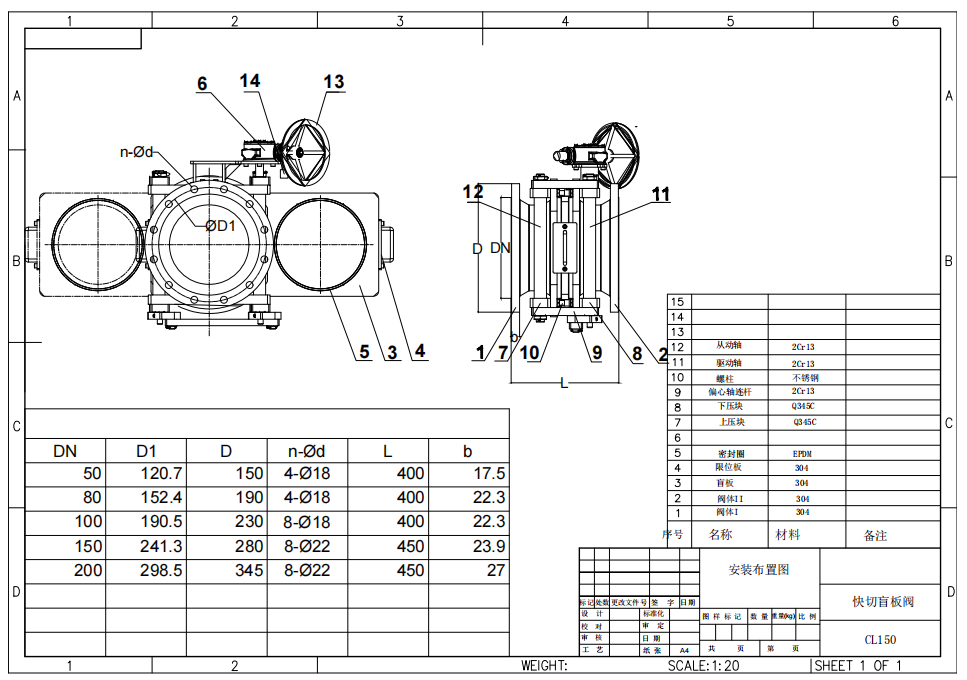

Technical Drawing

Line Blind Valves Technical Specifications

|

Description |

Standard |

|

Nominal Diameters |

1/2” (DN15) to 24” (DN600) |

|

Temperature Range |

-20°C to 816°C (14°F - 1500°F) |

|

Pressure Rating |

ASME Class 150 to 600 or higher on request |

|

Actuation Method |

Manual, Pnuematic, Hydraulic, Electric |

|

Materials |

Body: HT Carbon or Stainless Steel Plate: Stainless Steel Bellows: Stainless Steel |

Line Blind Valves Engineering Standards

|

ASME Standard |

Description |

|

B16.5 |

Pipe flanges and flanged fittings |

|

B16.34 |

Valves - flanged, threaded and welding end |

|

B31.1 |

Power piping |

|

ASME B&PV Code |

Description (Boiler & Pressure Vessel Code) |

|

Section II |

Material |

|

Section VIII |

Rules for Construction of Pressure Vessels |

|

Section IX |

Welding and Brazing Qualifications |

|

API Standard |

Description |

|

API 598 |

Valve inspection and testing |

|

API 2217 |

Guidelines for confined space work in the Petroleum Industry |

|

Others |

Description |

|

ISO 9001 |

Quality management system |

|

NACE MR0175 |

Sulfide stress cracking and stress corrosion |

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.