Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai ChinaLead Time:

35~60 days Ex Works After Order ConfirmationMaterial:

Carbon Steel Ball Valve, Cast Steel Ball Valve, WCBMethod of Operation:

Manual Ball Valve, Gear OperatedThe top entry full port ball valve with drain, vent and sealant injection is designed as per API 6D. The high pressure ball valve has Class 900 raised face flange and gearbox.

Quick Detail

|

Type |

Ball Valve |

|

Size |

16" |

|

Pressure |

ANSI 900 |

|

Construction |

1 Piece Body, Top Entry, Bolted Bonnet |

|

Connection |

Flanged End |

|

Operation Mode |

Gearbox |

|

Body Material |

A216 WCB |

|

Design & Manufacture |

API 6D |

|

Pressure & Temp Code |

ASME B16.34 |

|

End to End |

ASME B16.10 |

|

End Connection |

ASME B16.5 |

|

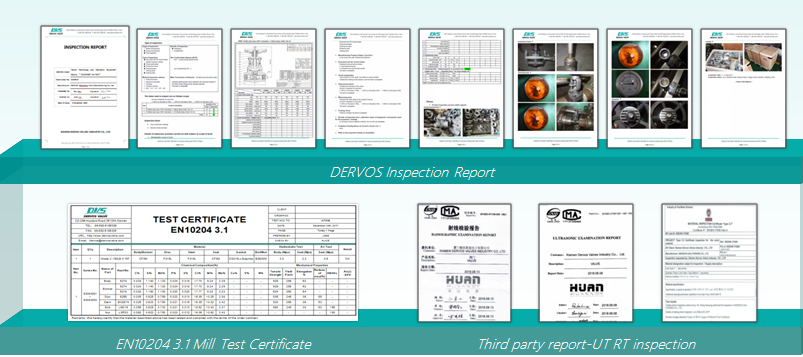

Inspection |

API 6D, API 598 |

|

Temperature Range |

-29℃~+200℃ |

|

Medium |

Oil, Water, Gas |

Related Knowledge

What is a top entry ball valve and its advantage?

A top entry ball valve is the valve which we assemble from the top side. It has a one single piece body. The less thread connection on the valve body means less weight and leakage paths. Plus, we could have access to the ball part without removing it from the pipeline. The top entry ball valves are often used in the pipeline with less maintenance for internal parts.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.