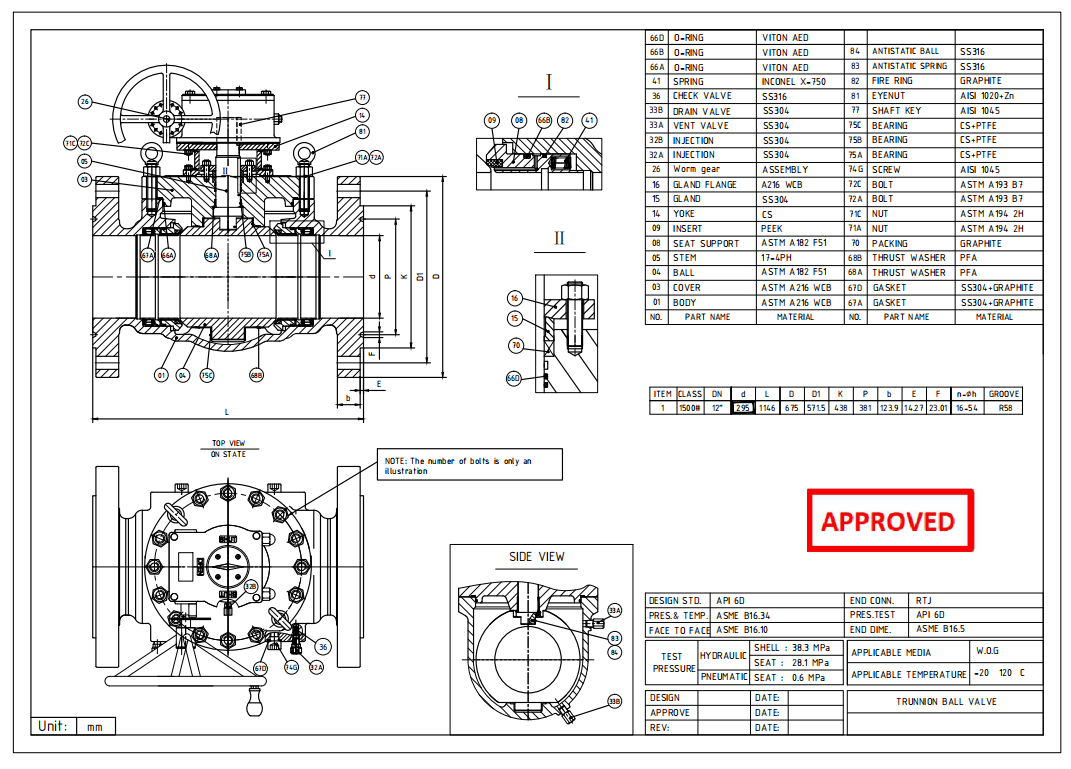

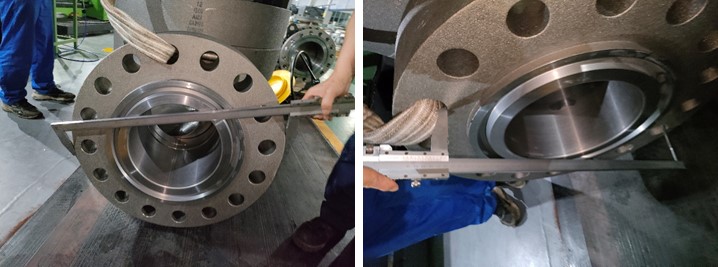

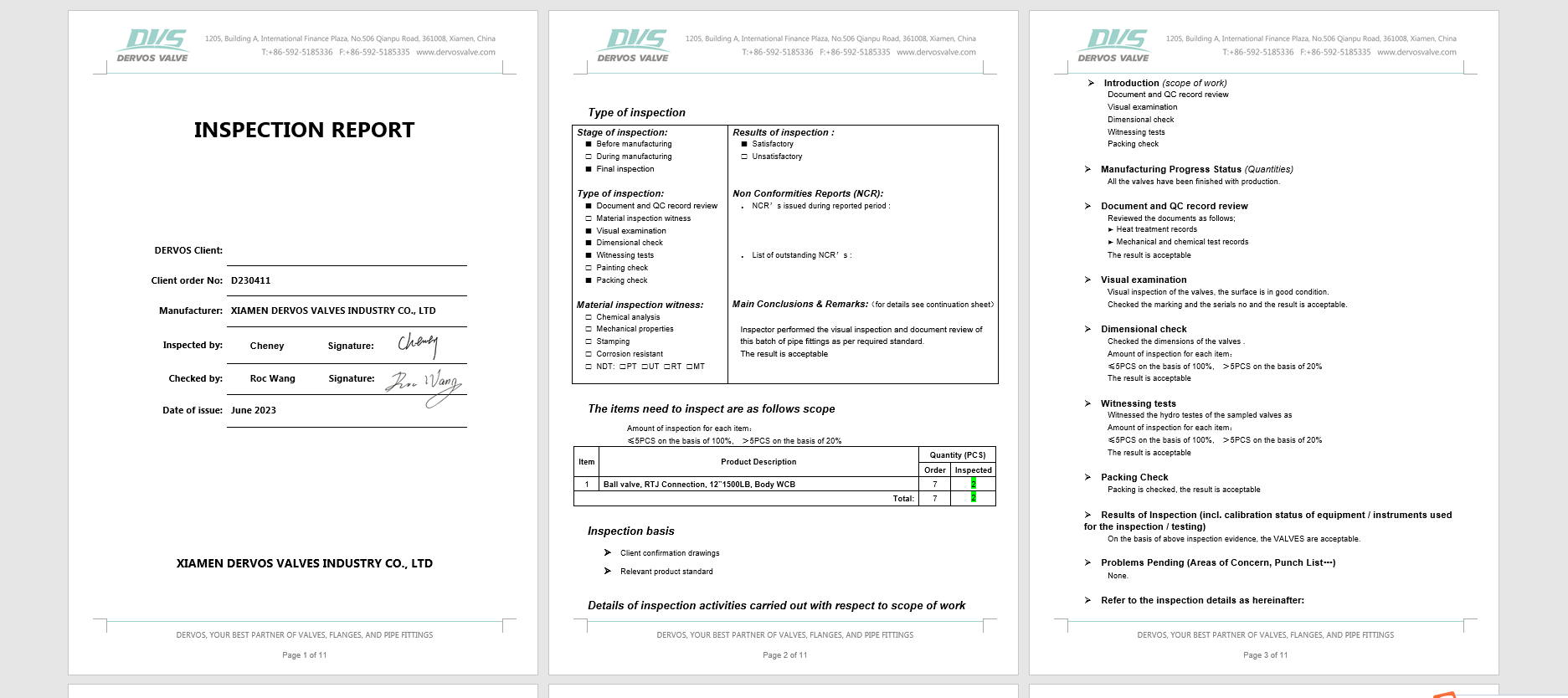

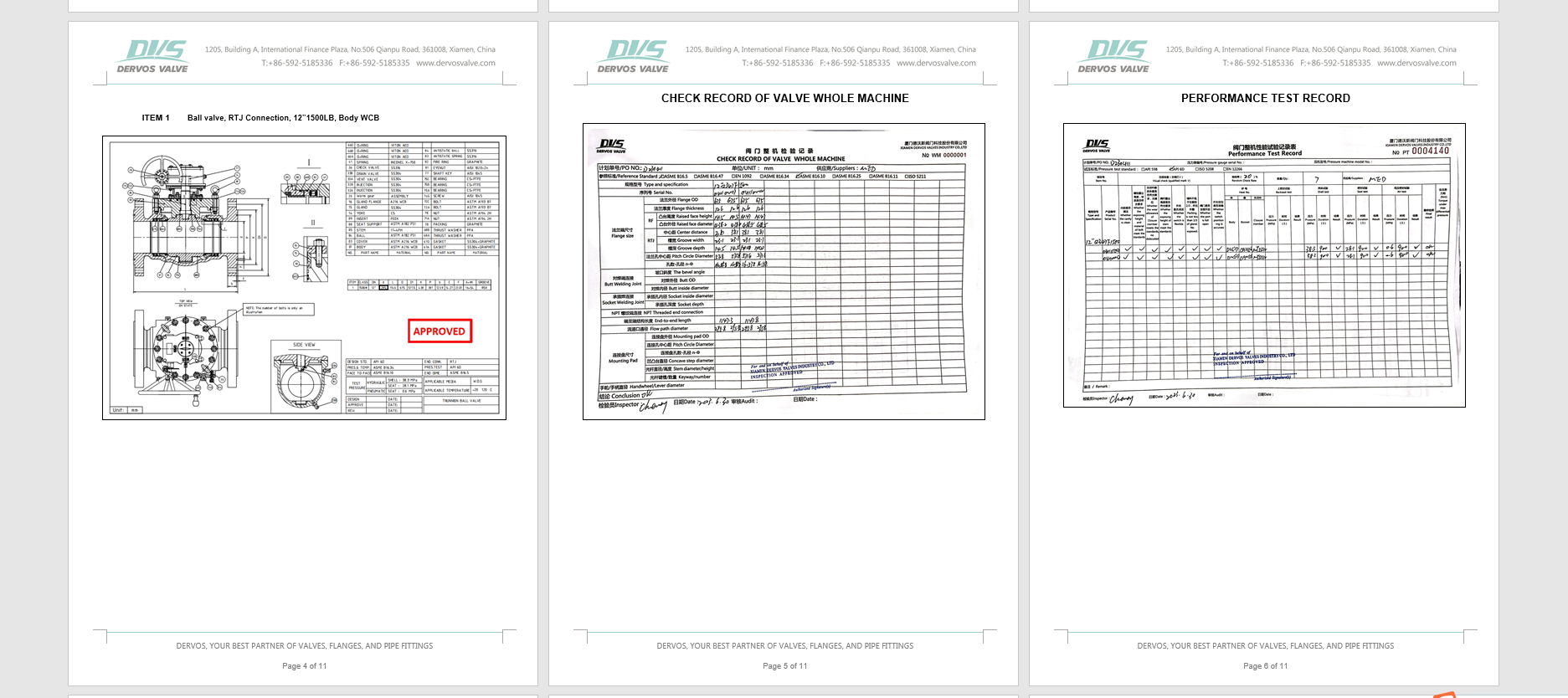

12" 1500LB top entry ball valve is made according to API 6D standard. The valve body is made of ASTM A216 WCB. It has the structural characteristics of top mounted, fixed ball, full bore, fire-safe design and anti-static, blowout-proof stem, inner diameter: 295mm. Its connection mode is RTJ. And it has turbine operation mode.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

ASTM A216 WCBMethod of Operation:

Turbine Operation|

Type |

Top Entry Ball Valve |

|

Size |

12" |

|

Pressure |

1500LB |

|

Connection |

RTJ |

|

Operation |

Turbine Operation |

|

Body Material |

ASTM A216 WCB |

|

Design Norm |

API 6D |

|

Pres. & Temp. |

ASME B16.34 |

|

Face to Face |

ASME B16.10 |

|

End Dime. |

ASME B16.5 |

|

Test & Inspection Code |

API 6D |

|

Temperature |

-20 ~ 120°C |

|

Applicable Medium |

Water, Oil and Gas |

1. The top-entry ball valve adopts a top-mounted structure, allowing for direct inline maintenance or replacement of the valve core and seals without removing the pipeline, significantly reducing maintenance workload and downtime;

2. It adopts a fixed seat design combined with high-quality sealing materials to ensure reliable bidirectional sealing performance, effectively preventing media leakage.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.