DN200 PN40 gate valve is made according to EN1984 standard. The valve body is made of 1.4571+STL. It has the structural characteristics of bolt cover, elastic gate, rising stem and bracket. Its connection mode is EN1092-1/B. And it has hand wheel operation mode.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

1.4571+STLMethod of Operation:

HW-OPProduct Description

|

Type |

Gate Valve |

|

Size |

DN200 |

|

Pressure |

PN40 |

|

Connection |

EN1092-1/B |

|

Operation |

HW-OP |

|

Body Material |

1.4571+STL |

|

Design Norm |

EN1984 |

|

Face to Face Dimensions |

Customer Standards |

|

Flange dimension |

EN1092-1/B1 |

|

Test & Inspection Code |

EN12266-1/2 |

|

Temperature |

-29 ~ 425°C |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. Low fluid resistance, effortless opening and closing, unrestricted medium flow direction;

2. Simple form, short structural length, good manufacturing process, and wide application range.

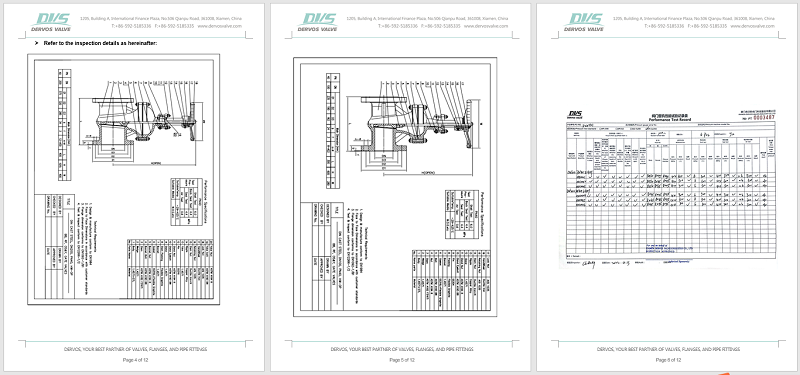

Technical Drawing

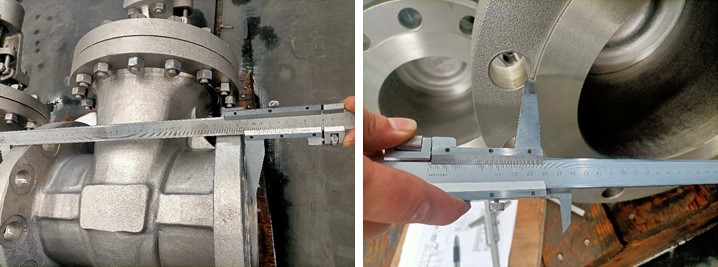

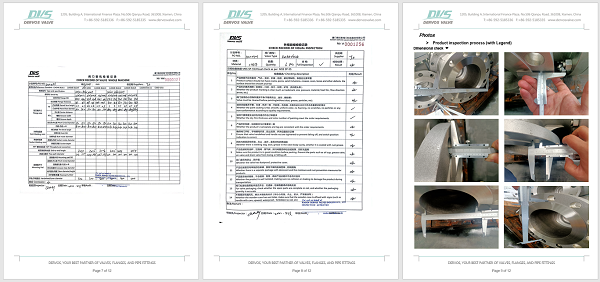

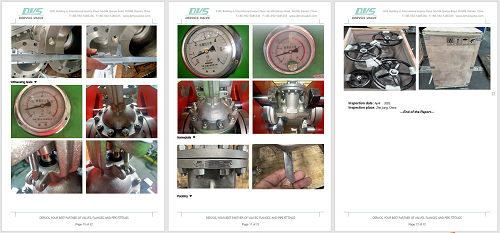

Dimension Checking

Pressure Testing

Nameplate & Packing

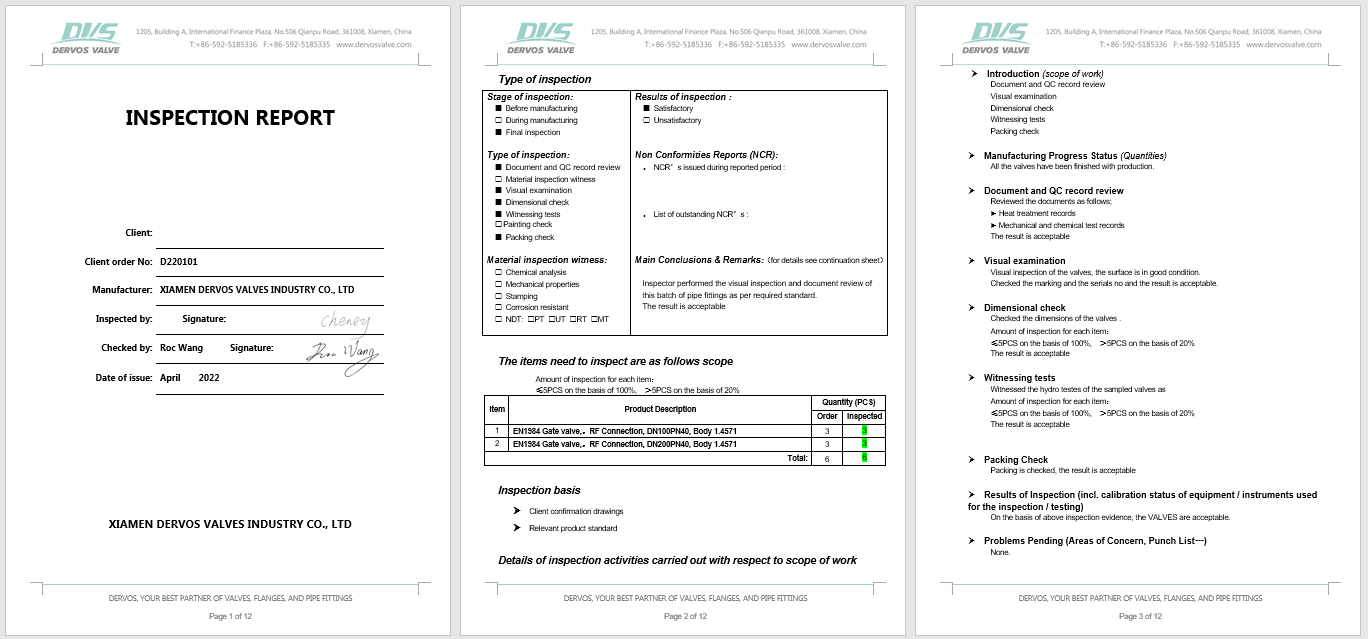

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.