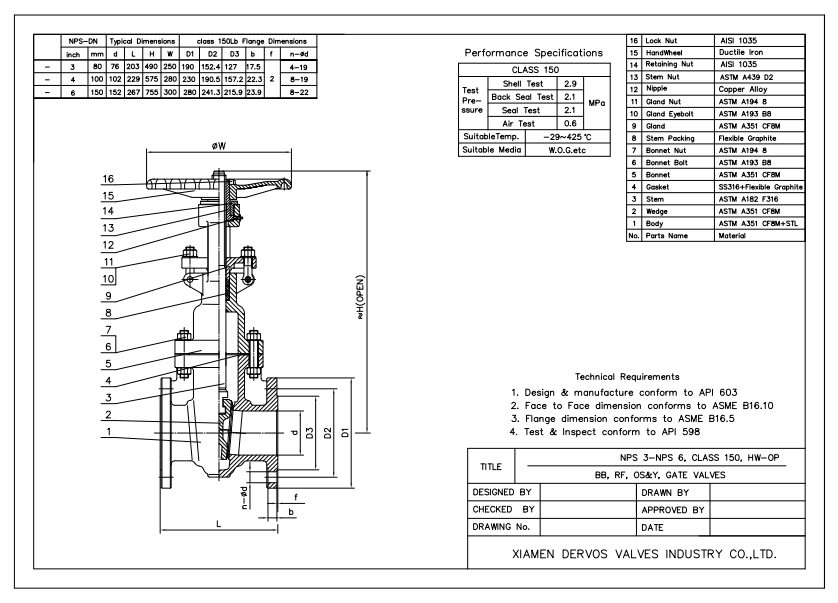

4" 150LB gate valve is made according to API 603 standard. The valve body is made of ASTM A351 CF8M+STL. It has the structural characteristics of bolt cover, elastic wedge and rising stem. Its test and inspection conform to API 598, and its operation mode is handwheel operation.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

ASTM A351 CF8M+STLMethod of Operation:

HW-OPProduct Description

|

Type |

Gate Valve |

|

Size |

4" |

|

Pressure |

150LB |

|

Connection |

RF |

|

Operation |

HW-OP |

|

Body Material |

ASTM A351 CF8M+STL |

|

Design Norm |

API 603 |

|

Face to face dimension |

ASME B16.10 |

|

Flange dimension |

ASME B16.5 |

|

Test & Inspection Code |

API 598 |

|

Temperature |

-29 ~ 425°C |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. The fluid resistance is small, and the sealing surface is less scoured and eroded by the medium;

2. Simple structure, short structure length and wide application range;

3. Good manufacturing process, high temperature and high pressure resistance, and many optional materials.

Technical Drawing

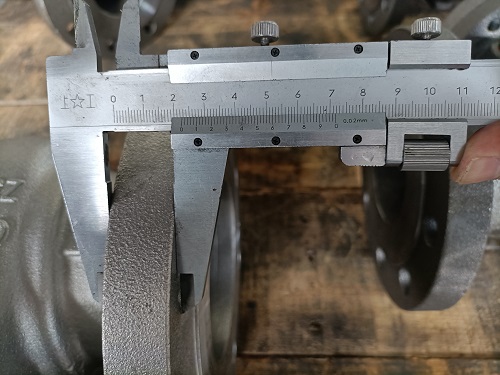

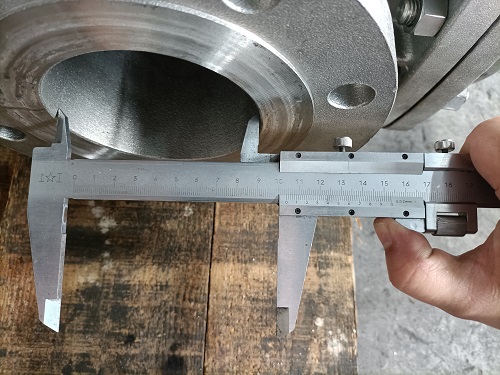

Dimension Checking

Pressure Testing

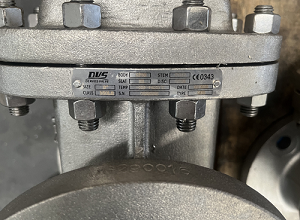

Nameplate & Packing

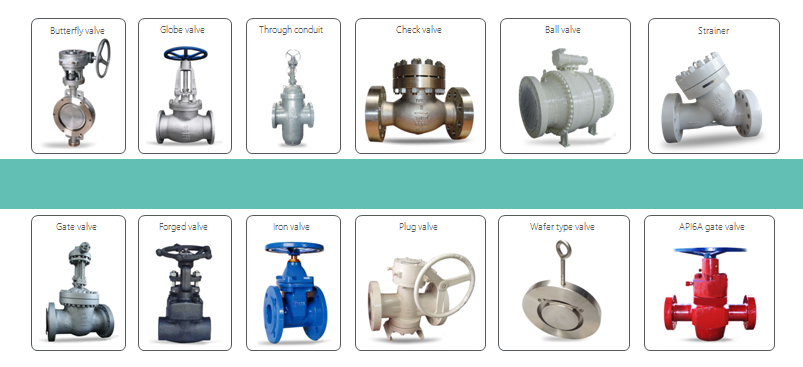

Our Main Product Range

Dervos main products include ball valves, butterfly valves, check valves, gate valves, globe valves, and plug valves in different materials, sizes, standards and types as per clients’ requests.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.