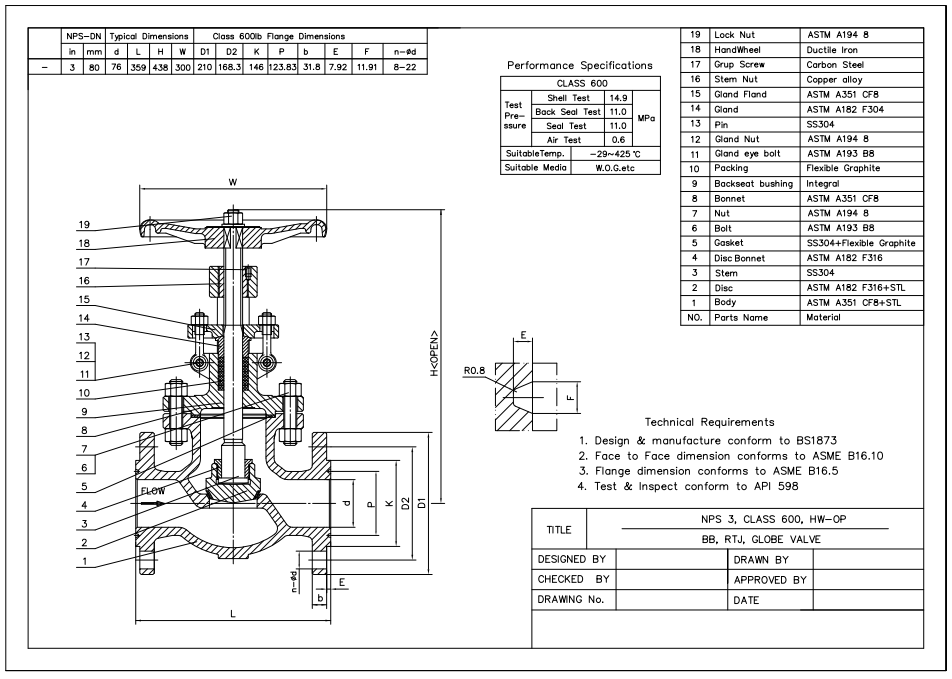

3" 600LB globe valve is made according to BS1873 standard. The valve body is made of ASTM A351 CF8+STL. It has the structural characteristics of bolt cover and straight through type. Its connection mode is RTJ. And it has hand wheel operation mode.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

ASTM A351 CF8+STLMethod of Operation:

Hand WheelProduct Description

|

Type |

Globe Valve |

|

Size |

3" |

|

Pressure |

600LB |

|

Connection |

RTJ |

|

Operation |

Hand Wheel |

|

Body Material |

ASTM A351 CF8+STL |

|

Design Norm |

BS1873 |

|

Face to Face Dimension |

ASME B16.10 |

|

Flange Dimension |

ASME B16.5 |

|

Test & Inspection Code |

API 598 |

|

Temperature |

-29 ~ 425°C |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. The manufacturing process is relatively good and easy to maintain;

2. Small working stroke and short opening and closing time;

3. Good sealing performance, low friction between sealing surfaces, and long service life.

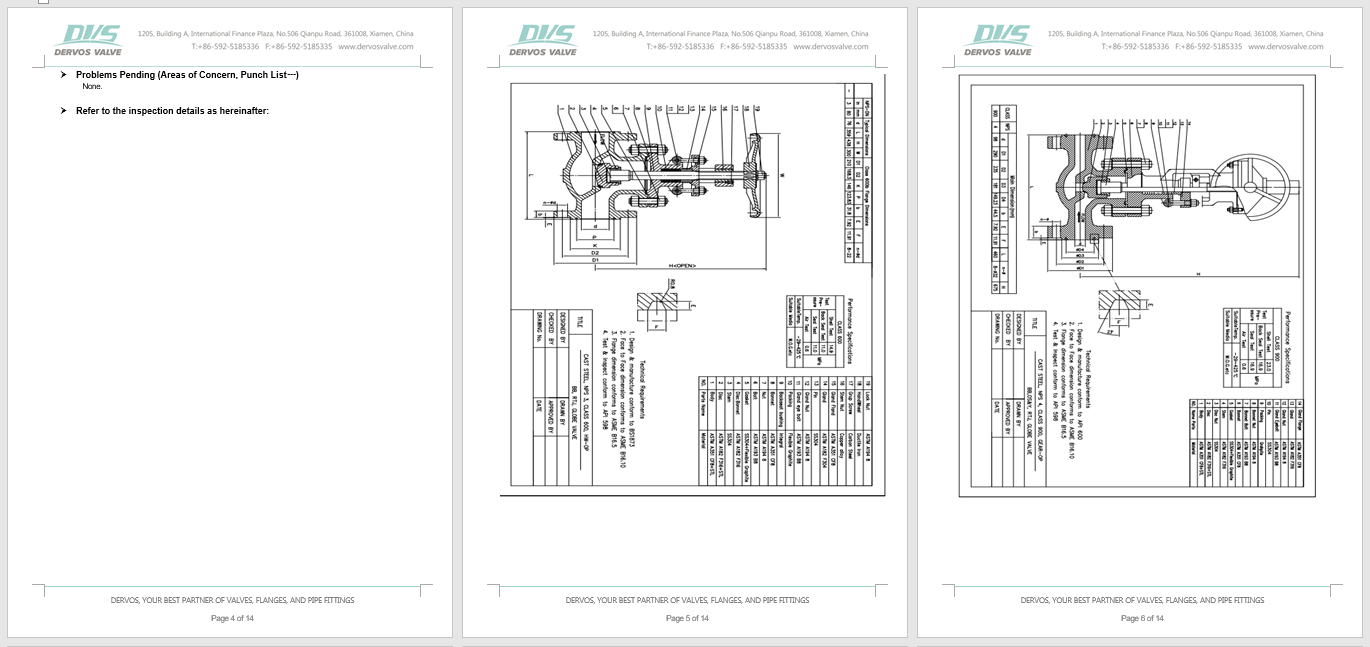

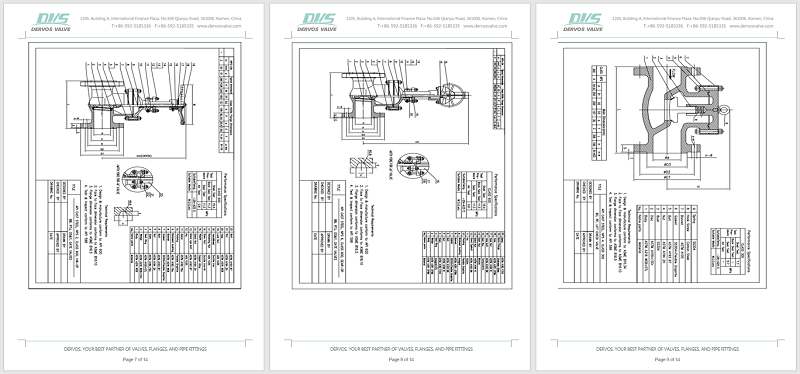

Technical Drawing

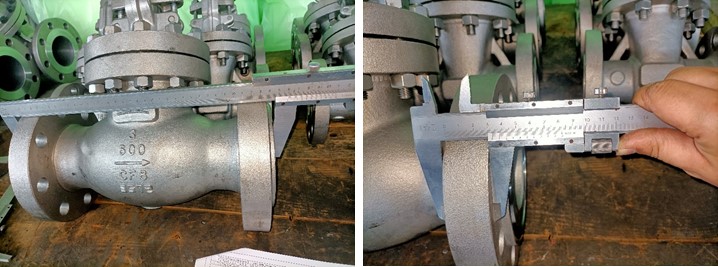

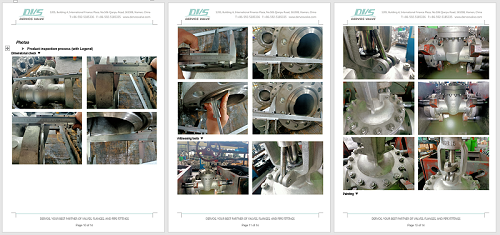

Dimension Checking

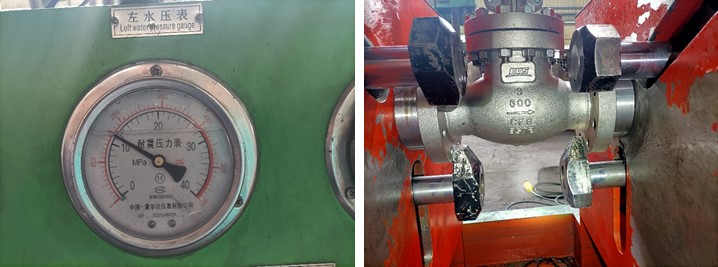

Pressure Testing

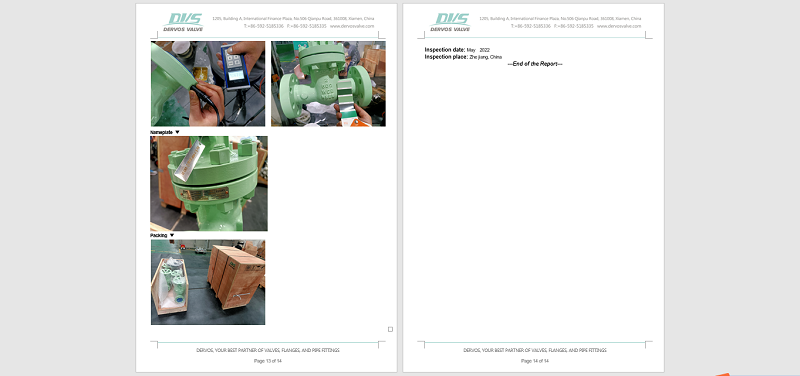

Packing

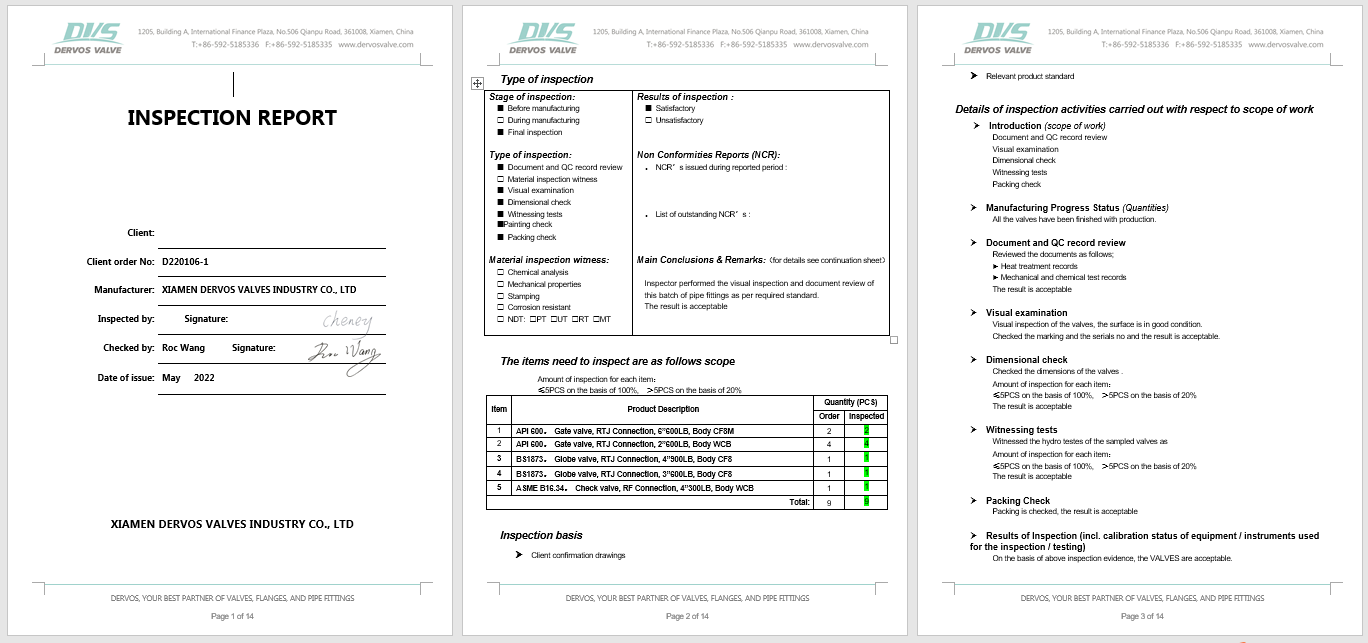

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.