Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai ChinaLead Time:

35~60 days Ex Works After Order ConfirmationMaterial:

Stainless Steel Globe ValveMethod of Operation:

Manual Globe Valve, Handwheel Globe ValveThe PN16 DN50 stainless steel flanged globe valve has straight pattern structure, bolted bonnet and handwheel operation. The OS&Y globe valve is designed as per DIN 3356.

Quick Detail

|

Type |

Globe Valve |

|

Norminal Size |

DN50 |

|

NorminalPressure |

PN16 |

|

Construction |

BB, Rising Stem, Plug Disc, Integral Seat |

|

ConnectionType |

Flange |

|

OperationType |

Gearbox |

|

Design Code |

DIN 3356 |

|

Face to Face |

DIN 3202 |

|

Flange End |

DIN 2543 |

|

Test & Inspection |

DIN 3230 |

|

Body Material |

Stainless Steel |

|

TrimMaterial |

Stainless Steel |

|

Temperature Range |

-196℃~+800℃ |

|

Medium |

Water, Oil and Gas |

|

Origin |

China |

Design Feature

1.Straight pattern body structure

2.OS&Y, Rising Stem

3.Bolted Bonnet

4.Available with bevel gear operation

5.Plug type disc

6.Little abrasion on sealing face during valve operation

7.Smaller installation space required

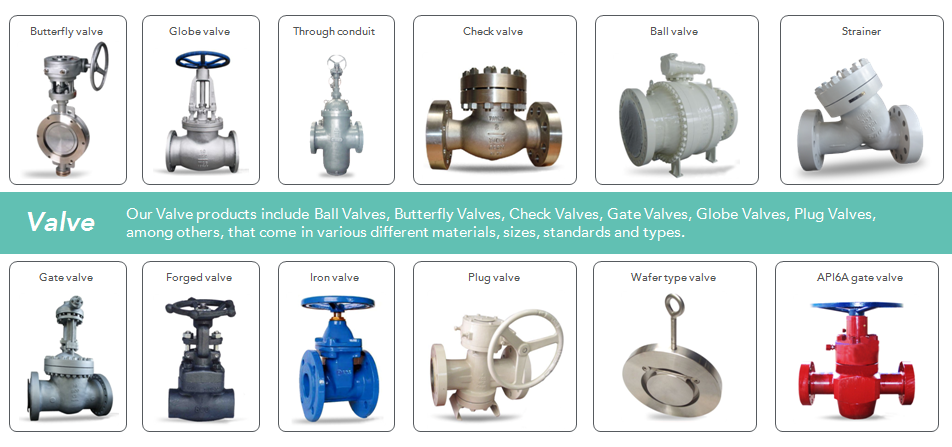

Dervos Main Product Range

With a complete product range, Dervos product lists cover gate, globe, check, ball, butterfly, check, plug valve and strainers. We can also provide marine valve, pressure reducing valve, control globe valve, wellhead valve and so on

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.