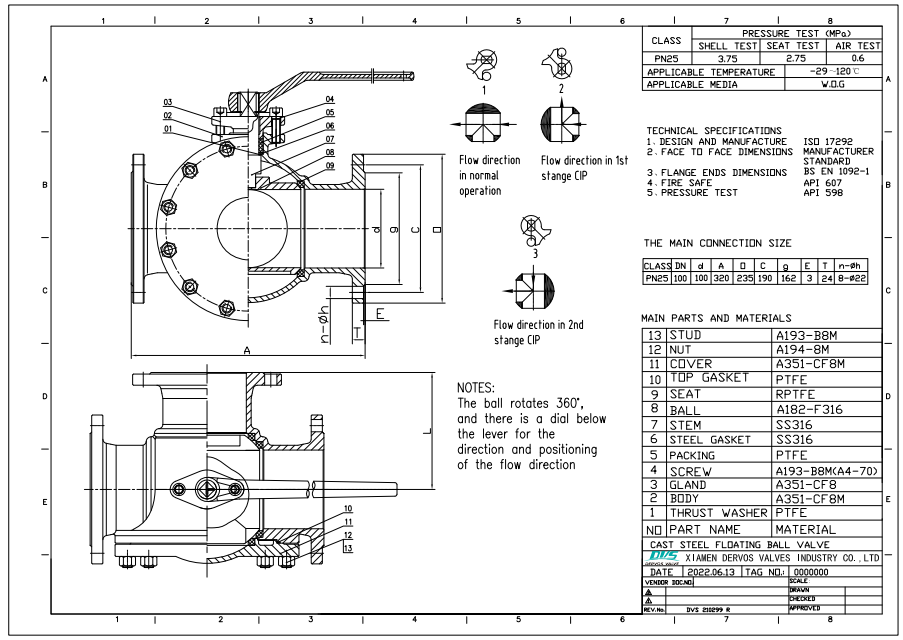

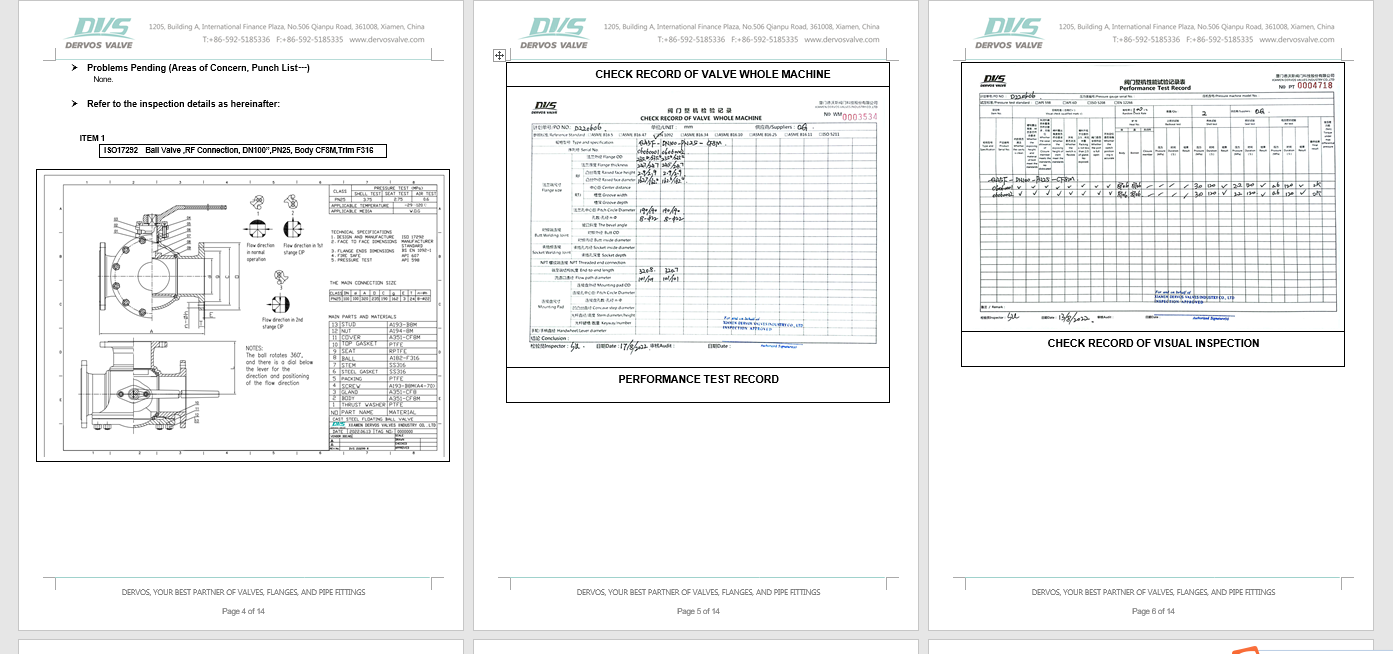

DN100 PN25 ball valve is made according to ISO 17292 standard. The valve body is made of A351-CF8M. It has the structural characteristics of T-shaped, floating ball, anti-fire, anti-static, anti-flying valve stem, bi-directional. Its connection mode is RF. And it has lever with dial operation mode.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A351-CF8MMethod of Operation:

Lever with dialProduct Description

|

Type |

Ball Valve |

|

Size |

DN100 |

|

Pressure |

PN25 |

|

Connection |

RF |

|

Operation |

Lever with dial |

|

Body Material |

A351-CF8M |

|

Design Norm |

ISO 17292 |

|

Face to Face Dimensions |

Manufacturer's Standard |

|

Flange Ends Dimensions |

BS EN 1092-1 |

|

Fire Safe |

API 607 |

|

Test & Inspection Code |

API 598 |

|

Temperature |

-29 ~ 120°C |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. Low fluid resistance, simple structure, small volume, and light weight;

2. Tight and reliable, with good sealing, convenient operation and maintenance.

Technical Drawing

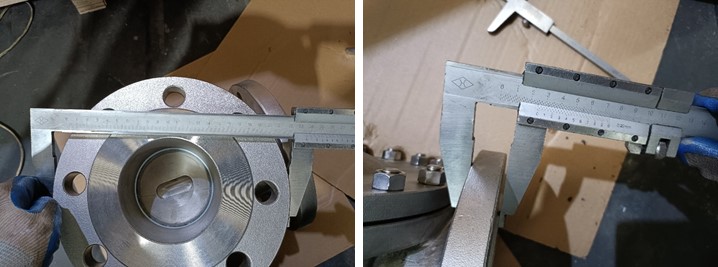

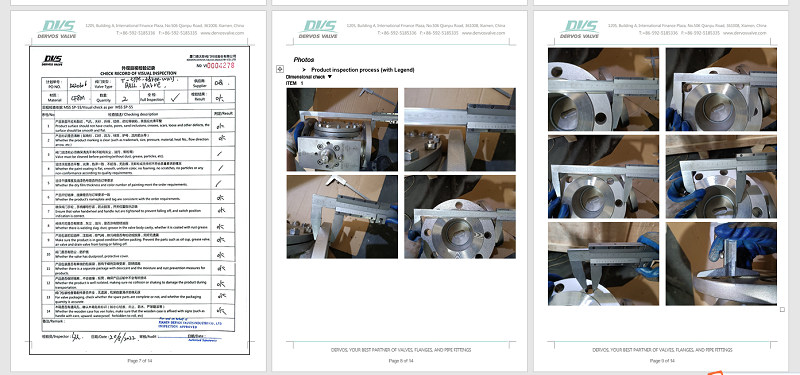

Dimension Checking

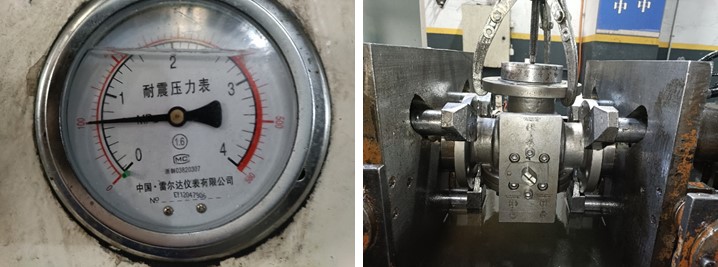

Pressure Testing

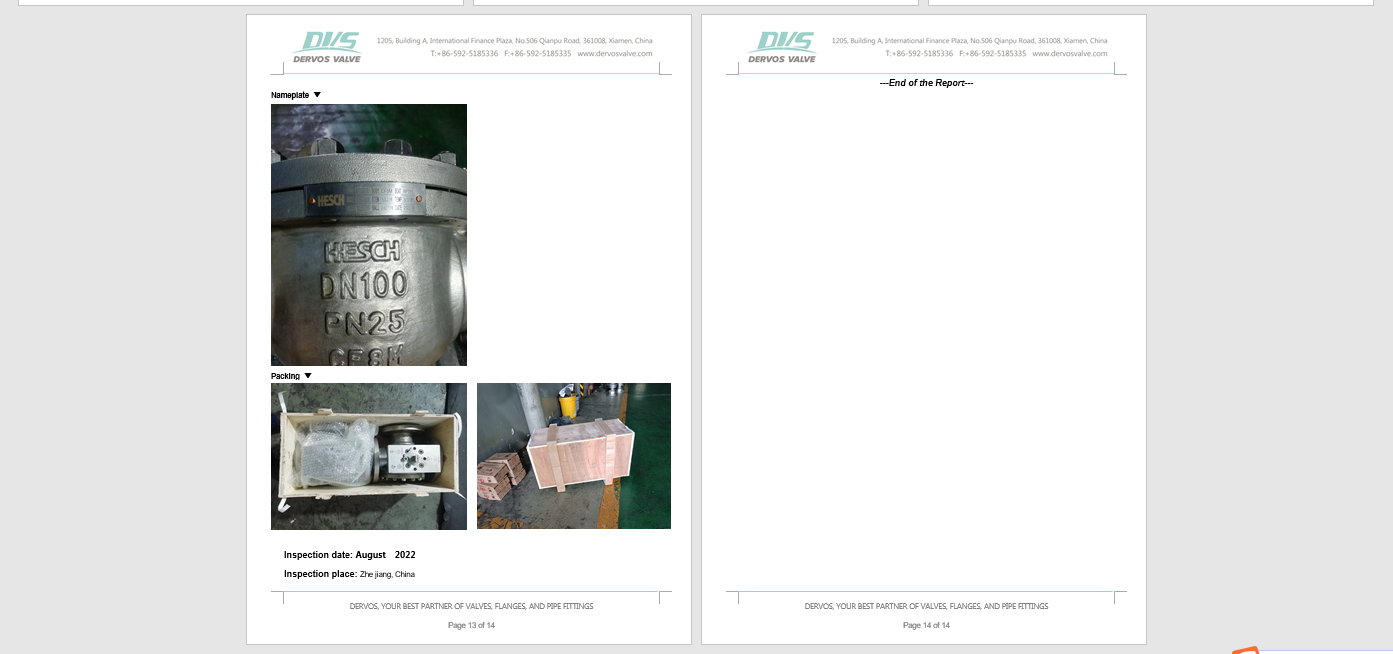

Nameplate & Packing

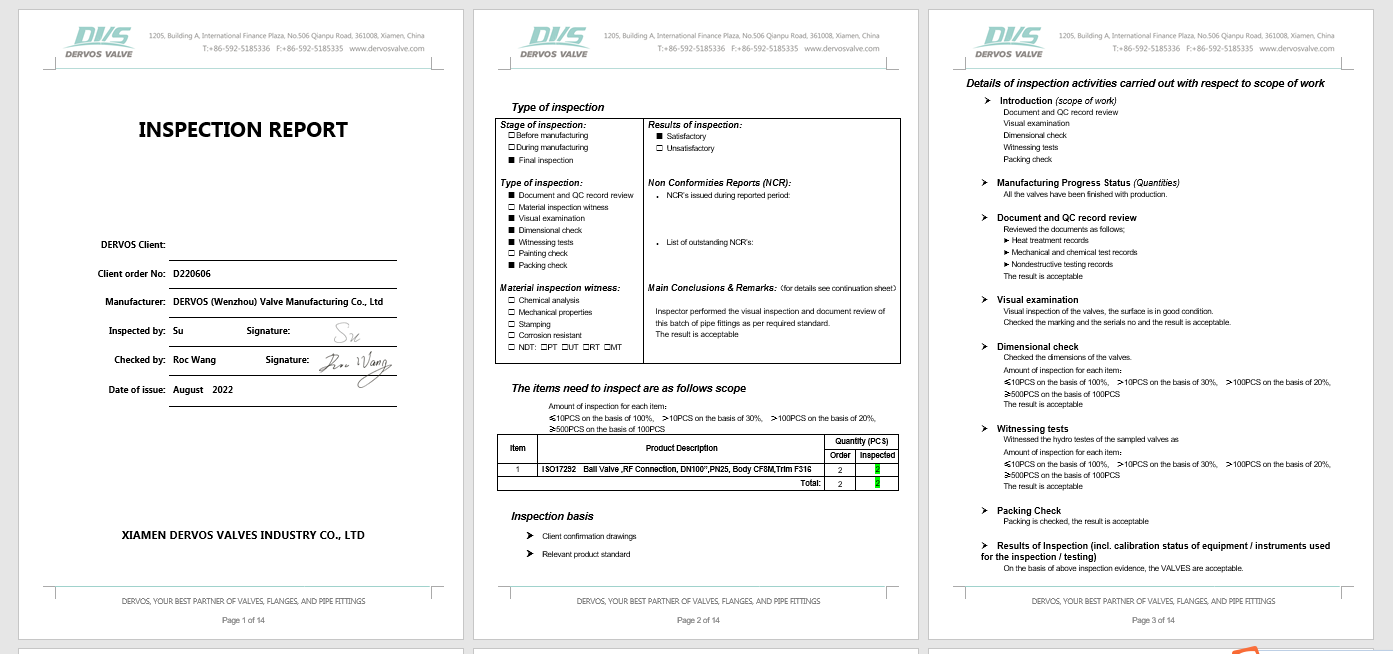

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.