Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

F5Method of Operation:

handwheelQuick Detail

|

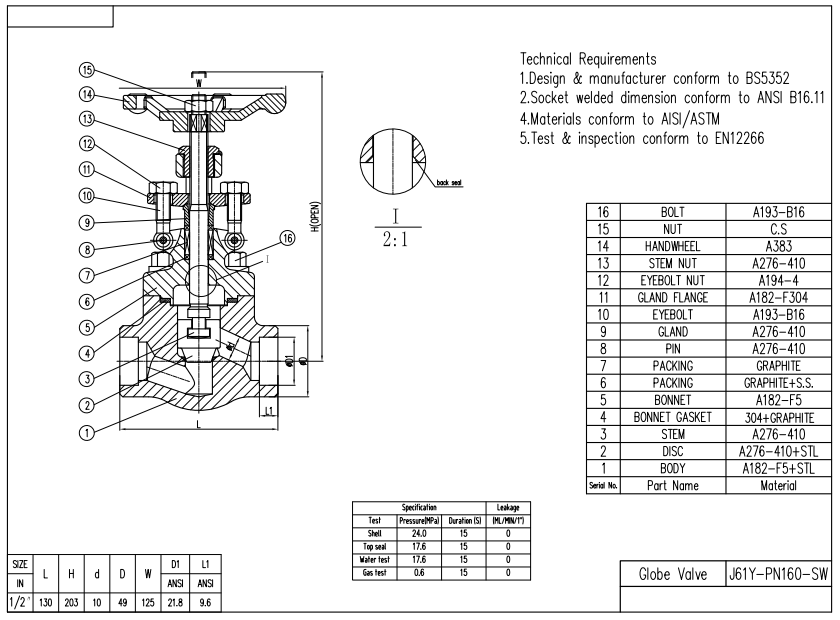

Type |

Globe Valve |

|

Size |

DN15 |

|

DesignPressure |

PN160 |

|

Construction |

Tee Pattern |

|

Connection |

Socket Welded |

|

Design & Manufacture |

BS5352 |

|

Socket Weld |

ANSI B16.11 |

|

Test & Inspection |

EN12266 |

|

Body Material |

A182 F5+STL |

|

Trim Material |

A276 410; STL |

|

Media |

WOG |

Description

--Tee Pattern is the most common type of globe valve with a z shaped diaphragm.

--The seat is oriented horizontally allowing the stem and disk to travel perpendicular to the horizontal line. This alsocontribute to low flow coefficient and higher pressure drop.

Features

--Good shutoff capability

--Moderate to good throttling capability

--Shorter stroke (compared to a gate valve)

--Available in tee,WYE, and angle patterns, each offering unique capabilities

--Easy to machine or resurface the seats

--With disc not attached to the stem, valve can be used as a stop-check valve

Technical Drawing

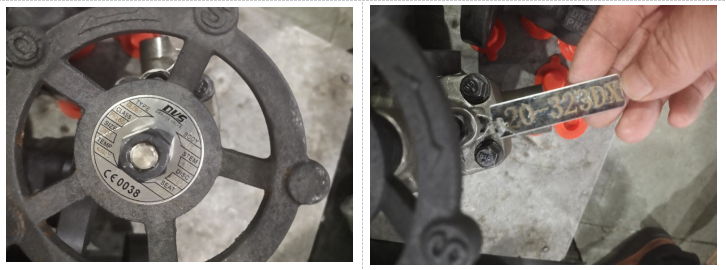

Dimension Check

Witnessing Tests

Nameplate & Packing

FAQ

1.Can the ordersalways be delivered on time?

Our purchasingteam follows up very closely with each order tomake sure on-time delivery for most of orders. In 2018,more than 90% orders were delivered on time, and we are dedicated to doing better.

2.What’s the normal delivery lead time?

For normal material, usually the delivery time is about 35~40 days, and for forged material, the delivery canevenbe shortened to 20~25 days. We believe the short lead time can make our offer more competitive and help you secure more orders.

Do you have different price levels for us?

With our numerous suppliers, different price levels are available with us, so we are able to help you win more customer from different markets requesting for high, medium and low prices.

About Dervos

Xiamen Dervos Valves Industry Co.,Ltd (stock code 861601), founded in June 2008, is a one-stop industrial valves supplier integrated of R&D, manufacture, resource integration, and trade service. For 12 years, Dervos has been committed to finding solutions for industrial needs and providing professional service for both general and specialized valves.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.