The DN100 3 way ball valve is isolating valve designed to redirect the service fluid flow rather than throttling or regulating purposes. Suitable for water, steam, gas, oil, crude oil, acid, alkali and other liquids and gases without mechanical impurities.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

CF 8MMethod of Operation:

NonQuick Detail

|

Type |

Ball Valve |

|

Size |

DN100 |

|

Pressure |

PN10 |

|

Construction |

Three-way, Full Bore,Floating Ball |

|

Connection |

RF Flange End |

|

Operation Mode |

Bare Stem |

|

Body Material |

CF8M |

|

Trim Material |

CF8M Ball,SS316 Stem,PTFE Seat |

|

Design & Manufacture |

ISO17292 |

|

Pressure & Temp Code |

API598 |

|

Fire Safe |

API607 |

|

End Connection |

BS EN 1092-1-B1 |

|

Temperature Range |

-29℃~120℃ |

|

Medium |

Oil, Water, Gas |

Features

Bore Type – Full Bore

Floating Ball Valves

Blow- Out Proof Stem

DervosValves has very extended experience in manufacturing of Three Way Ball Valves

Size 1/2” to 8“(DN 15 to DN 200)

Pressure Rating: ASME 150# to 300#

Materials: Carbon Steel, Low Temperature Carbon Steel, Stainless Steel, Duplex Stainless Steel, Super Duplex Stainless Steel, etc.

Seating: Soft Seated (PTFE/RPTFE /PEEK/NYLON/DEVLON) and Metal Seated

End Connection: Flanged FF/RF/RTJ

Actuator: Lever/Wrench, Gear, Actuator (Pneumatic, Hydraulic, Electric, Motorized, Electro-Hydraulic)

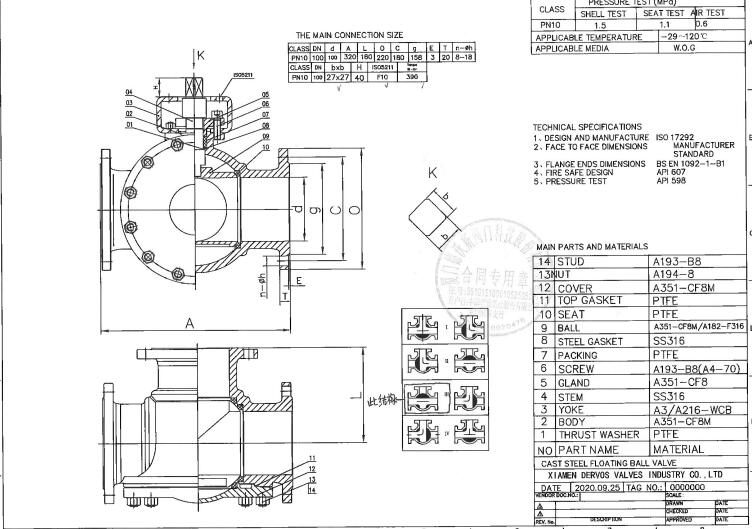

Technical Drawing

Dimension Check

Witness Test

Packing

About Dervos

Xiamen Dervos Valves Industry Co.,Ltd (stock code 861601), founded in June 2008, is a one-stop industrial valves supplier integrated of R&D, manufacture, resource integration, and trade service. For 12 years, Dervos has been committed to finding solutions for industrial needs and providing professional service for both general and specialized valves.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.