The high-pressure

Class 4500 gate valve is designed with PSB and SW end connection. Made of CS

A105, the 2 inch gate valve follows the inspection standard API 598 and design

standard API 602.

Dervos could offer customizing service by providing clients with valves in

different sizes, materials, standards, design pressure, structure, operation

type and connection type.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

CS A105Product Description

|

Type |

Gate Valve |

|

Size |

2" |

|

PN |

Class 4500 |

|

Construction |

Pressure Seal Bonnet, OS&Y |

|

Connection |

SW |

|

Operation |

Handwheel |

|

Body |

CS A105 |

|

Design Standared |

API 602 |

|

Face to Face Code |

ANSI B16.10 |

|

Pressure & Temp |

ANSI B16.34 |

|

Test & Inspection |

API 598 |

|

Temp. |

-29℃ ~ +425℃ |

|

Medium |

Water, Oil and Gas |

|

Origin |

China |

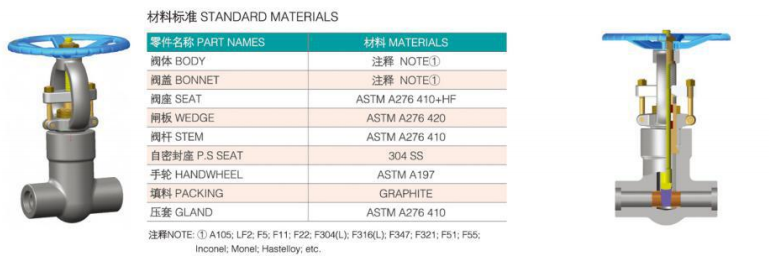

Material

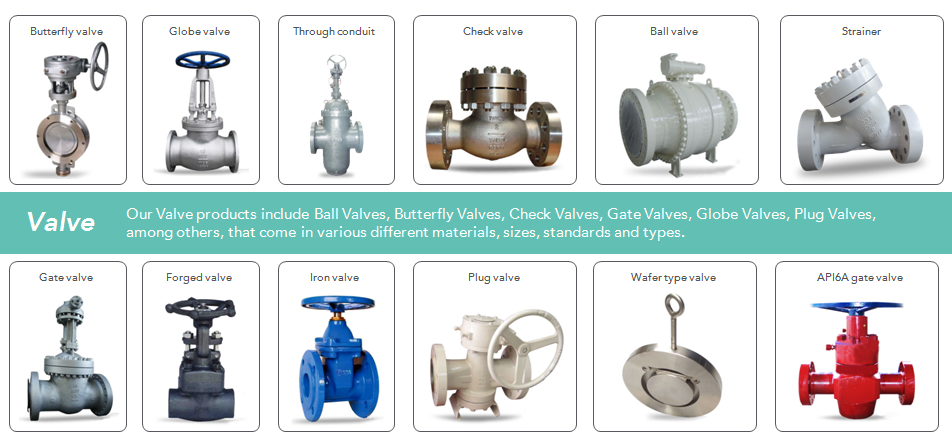

Product Range

Our products include different kind of valves as below. Or you want to know more detail, just contact us.

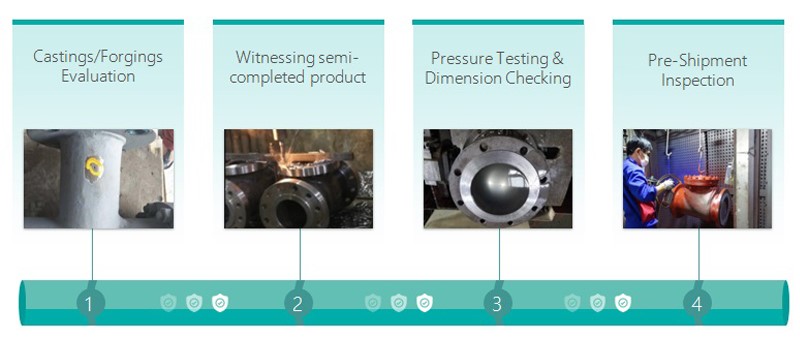

Quality Inspection

Dervos strictly controls product quality. In addition to the final round of inspections, our quality inspection team also checks valve quality through casting or forging, machining, pressure testing, dimensional inspection, painting and packaging.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.