The knife gate is a bi-directional lug type valve designed according to MSS-SP-81 and for industrial service applications. The design of the body and seat assures non-clogging shut off on suspended solids in industries.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

2205Method of Operation:

HandwheelQuick Detail

|

Type |

KnifeGate Valve |

|

Size |

6'' |

|

Design Pressure |

150LB |

|

Construction |

Knife Type Gate Valve |

|

Connection Type |

Lug Type, RF |

|

Operation Type |

Hand wheel |

|

Body Material |

2205 |

|

Seat Material |

EPDM |

|

Design Code |

MSS SP-81 |

|

Flange Dimensions |

ASME B16.5 |

|

Temp. Range: |

-29~.+120℃ |

|

Medium |

Water, Oil and Gas |

|

Origin |

China |

Features

All stainless steel design

Standard knife gate valves: NPS 2–24 (DN 50–600)

Bolted bonnet knife gate valves: NPS 4–24 (DN 50–600)

ASME Classes: 1690-4500

0-14ph packing standard

Locking device on standard knife gate valve

Environmentally friendly bi-directional bolted bonnet and standard body styles

Resilient and metal seats

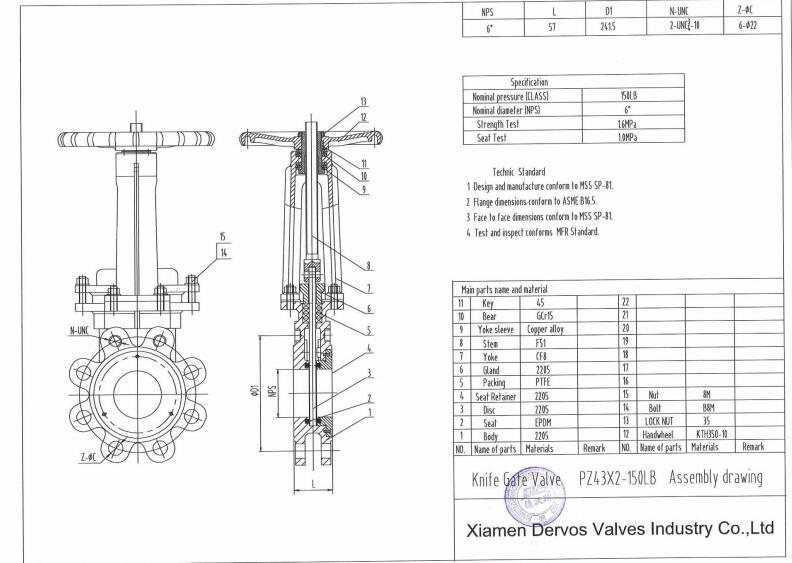

Technical Drawing

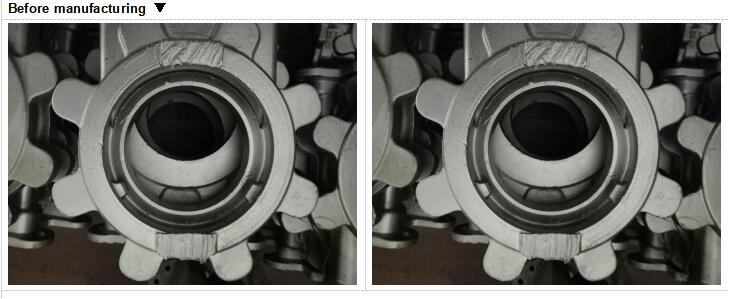

Before Manufacturing

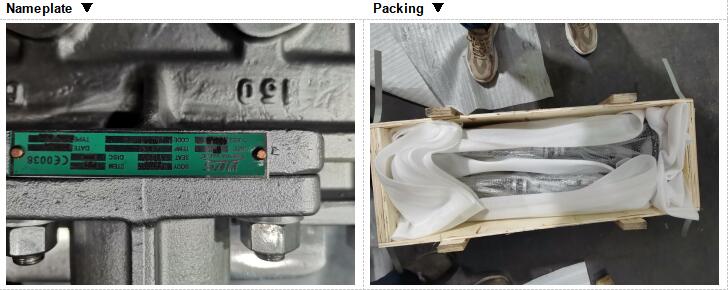

Nameplate&Packaging

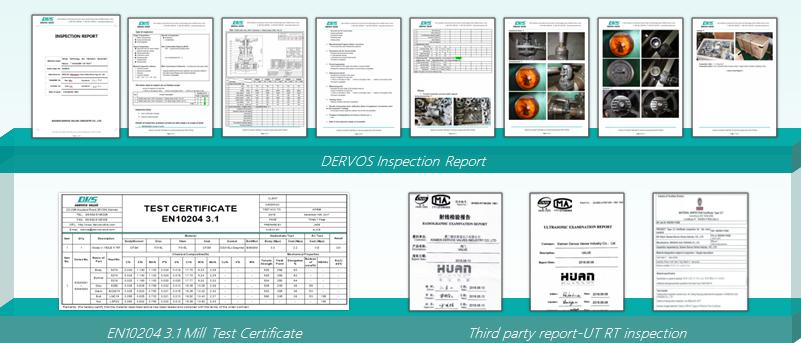

Reports

For each order, Dervos will provide inspection reports to show you the whole inspection process and results. Plus, we will provide material report to let you know that the material we provide is as per standards.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.