The DN150 PN10 unidirectional knife gate valve features a single piece, stainless steel body design provides tested performance in applications ranging from general purpose to severe media.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

CF8MMethod of Operation:

HandwheelQuick Details

|

Type |

Gate Valve |

|

Size |

DN150 |

|

Pressure |

PN10 |

|

Construction |

Knife Gate Valve |

|

Connection |

Wafer RF |

|

Operation |

Handwheel |

|

Body Material |

CF8M |

|

Design Code |

MSS-SP-81 |

|

Face to Face Code |

GB/T12221 |

|

Flange Dimensions |

DIN EN 1092-1 |

|

Test & Inspection Code |

API 598 |

|

Temperature Range |

-196℃~600℃ |

|

Medium |

Water, Oil, Gas, Pulp |

|

Origin |

China |

Features

Designed for easy, quick switch between manual and pneumatic actuation.

Standard multi-layer square packing provides exceptional gland sealing

Optional energized quad seal packing for enhanced gland sealing

Standard integral metal seat with optional replaceable Class IV metal or Class VI resilient seats

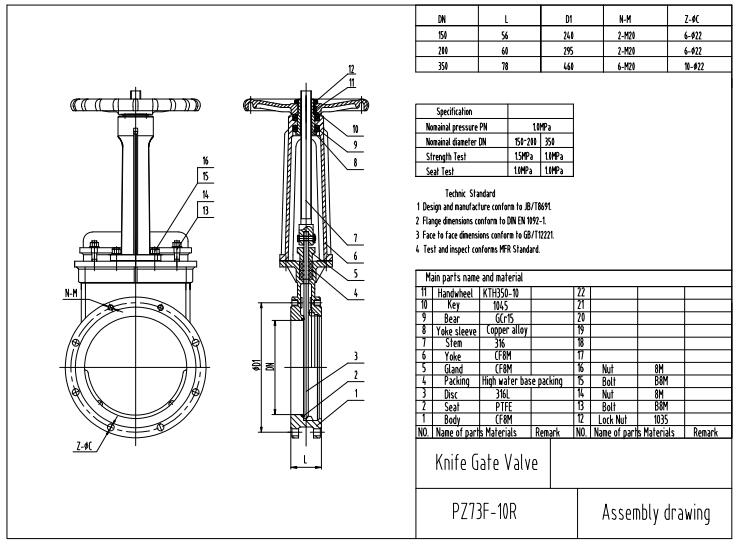

Technical Drawing

Dimension Check

Witnessing Test

Packing

FAQ

1. How long have you been in business and how long have you producing valves?

We have been in valve exporting industry for more than 10 years since foundation in 2008. Our business has expanded tremendously to five continents all around the world.

2. What are your main products and their advantages?

Our main products include gate, globe, check, ball, butterfly, plug valves and strainers, available in different materials, sizes and pressure, which are widely used in various industries.

3. Does Xiamen Dervos Valves Industry Co., Ltd. make products for other companies?

Yes, of course. We have a reference list with customer information like country, product type, order volume and some even with project names.

About Us

Xiamen Dervos Valves Industry Co.,Ltd (stock code 861601), founded in June 2008, is a one-stop industrial valves supplier integrated of R&D, manufacture, resource integration, and trade service. For 12 years, Dervos has been committed to finding solutions for industrial needs and providing professional service for both general and specialized valves.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.