Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai ChinaLead Time:

30~55 days Ex Works After Order ConfirmationMaterial:

Cast Steel Gate Valve, Carbon Steel Gate ValveMethod of Operation:

Gear Operated Gate ValveQuick Detail

|

Type |

Gate Valve |

|

Size |

16" |

|

Pressure |

Class600 |

|

Construction |

Bolted Bonnet, Rising Stem, OS&Y, Flexible Wedge, Metal Seat |

|

Connection |

RF Flange |

|

Operation |

Gearbox |

|

Design Code |

API 600 |

|

Face to Face |

ASME B16.10 |

|

Flange End |

ASME B16.5 |

|

Pressure & Temp |

ASME B16.34 |

|

Test & Inspection |

API 598 |

|

Body Material |

A216 WCB |

|

TrimMaterial |

Trim 5 |

|

Temperature Range |

-29℃~+425℃ |

|

Medium |

Water, Oil and Gas |

|

Origin |

China |

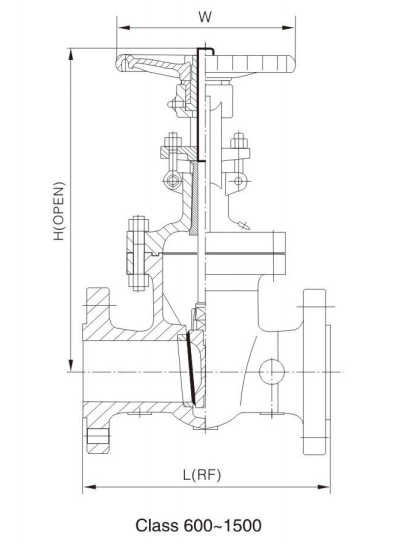

Dimension & Material

| Class 600 | ||||||||||||||

| NPS | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| DN | mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

|

L-L1 (RF-BW) |

in | 11.5 | 13 | 14 | 17 | 22 | 26 | 31 | 33 | 35 | 39 | 43 | 47 | 55 |

| mm | 292 | 330 | 356 | 432 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 | 1397 | |

|

L2 (RTJ) |

in | 11.625 | 13.125 | 14.125 | 17.125 | 22.125 | 26.125 | 31.125 | 33.125 | 35.125 | 39.125 | 43.125 | 47.25 | 55.375 |

| mm | 295 | 333 | 359 | 435 | 562 | 664 | 791 | 841 | 892 | 994 | 1095 | 1200 | 1407 | |

|

H (OPEN) |

in | 18.625 | 21.75 | 23.375 | 28 1/16 | 38 3/16 | 44 3/16 | 52.375 | 59 13/16 | 68.125 | 72.25 | 90.125 | 98 13/16 | 119 |

| mm | 474 | 553 | 593 | 713 | 970 | 1122 | 1330 | 1519 | 1730 | 1835 | 2290 | 2510 | 3022 | |

| W | in | 9.875 | 9.875 | 11 13/16 | 13.75 | 19 11/16 | 22 1/16 | 28.375 | 24 | 24 | 24 | 24 | 30 | 30 |

| mm | 250 | 250 | 300 | 350 | 500 | 560 | 720 | 610* | 610* | 610* | 610* | 760* | 760* | |

|

WT (kg) |

RF | 41 | 58 | 88 | 131 | 253 | 413 | 623 | 784 | 1288 | 1820 | 2150 | 2540 | 4080 |

| BW | 35 | 50 | 68 | 104 | 208 | 328 | 496 | 637 | 1120 | 1448 | 1828 | 2201 | 3360 | |

| *Manual gear operator is recommended | ||||||||||||||

| No | Part Name | Carbon steel to ASTM | Alloy steel to ASTM | Stainless steel to ASTM | ||||||

| WCB | LCB | WC6 | WC9 | C5 | CF8 | CF8M | CF3 | CF3M | ||

| 1 | Body | A216 WCB | A350 LCB | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 2 | Seat Ring | A105 | A350 LF2 | A182 F11 | A182 F22 | A182 F5 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 3 | Wedge | A216 WCB | A350 LCB | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 4 | Stem | A182 F6 | A182 F6 | A182 F304 | A182 F304 | A182 F316 | A182 F304L | A182 F316L | ||

| 5 | Bonnet nut | A194 2H | A194 4 | A194 7 | A194 8 | |||||

| 6 | Bonnet bolt | A193 B7 | A320 L7 | A193 B16 | A193 B8 | |||||

| 7 | Gasket | SS Spiral Wound graphite or SS Spiral Wound PTFE | ||||||||

| 8 | Bonnet | A216 WCB | A352 LCB | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 9 | Backseat bushing | A182 F6 | A182 F6 | A182 F304 | A182 F304 | A182 F316 | A182 F304L | A182 F316L | ||

| 10 | Stem packing | Graphite or PTFE | ||||||||

| 11 | Lantern | A182 F6 | A182 F6 | A182 F304 | A182 F304 | A182 F304 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 12 | Gland Nut | A194 2H | A194 8 | |||||||

| 13 | Gland Eyebolt | A193 B7 | A193 B8 | |||||||

| 14 | PIN | Carbon steel or Stainless Steel | ||||||||

| 15 | Gland | A182 F6 | A182 F304 | A182 F316 | A182 F304L | A182 F316L | ||||

| 16 | Gland Flange | A216 WCB | A351 CF8 | |||||||

| 17 | Stem Nut | A439 D2 or B148-952A | ||||||||

| 18 | Nipple | Carbon steel or Stainless Steel | ||||||||

| 19 | Retaining Nut | Carbon steel | ||||||||

| 20 | Hand Wheel | Ductile Iron or carbon steel | ||||||||

| 21 | Name Plate | Stainless steel or Aluminum | ||||||||

| 22 | H.W.Lock Nut |

Carbon steel |

||||||||

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.