Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai ChinaLead Time:

30~55 days Ex Works After Order ConfirmationMaterial:

Carbon Steel Plug Valve, Cast Steel Plug Valve, WCBMethod of Operation:

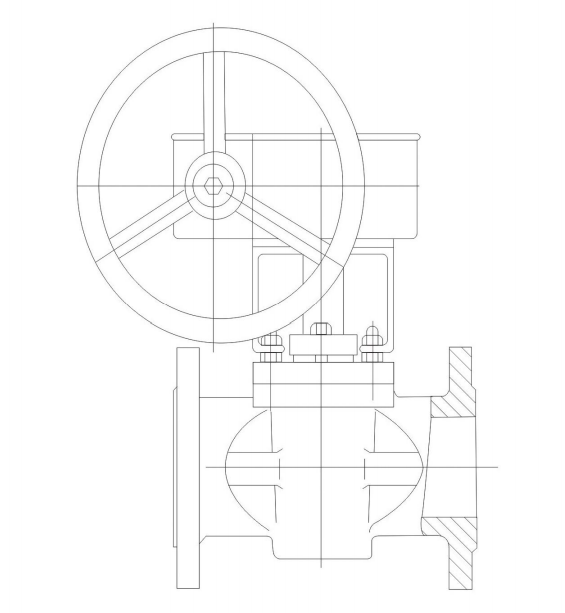

Manual Plug Valve, Gearbox Operation Plug ValveThe 6 inch sleeved plug valve features in non lubricated design and soft seat. The full port plug valve is made of carbon steel body and PTFE seat as per API 6D, with Class 150 flange connection.

Quick Detail

|

Type |

Plug Valve |

|

Size |

6'' |

|

Design Pressure |

150LB |

|

Construction |

Self-Lubricated Type, Sleeved Type, Soft Seat |

|

Connection Type |

RF Flange |

|

Operation |

Gearbox Operation |

|

Design Code |

API 599 |

|

Face to Face |

ASME B16.10 |

|

End Connection |

ASME B16.5 |

|

Pressure & Temp |

ASME B16.34 |

|

Test & Inspection |

API 598 |

|

Body Material |

A216 WCB |

|

Temperature Range |

-29℃~+425℃ |

|

Application |

Water, Oil, Gas |

Material & Dimension

| No | Part Name | Carbon steel to ASTM | Stainless steel to ASTM | ||||

| WCB | LCB | CF8 | CF8M | CF3 | CF3M | ||

| 1 | Body | A216 WCB | A350 LCB | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 2 | Bonnet | A216 WCB | A350 LCB | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 3 | Plug | A105 | A182 F304 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 4 | Stem | A182 F6 | A182 F6 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 5 | Seat Ring | PTFE | |||||

| 6 | Gasket | PTFE or Stainless Steel and Graphite | |||||

| 7 | Stem Seat | PTFE | PTFE | PTFE | PTFE | PTFE | PTFE |

| 8 | Small spring | 17-17PH | |||||

| 9 | Small ball | A182 F304 or A182 F316 | |||||

| 10 | Gland | A182 F6 | A182 F6 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 11 | Gland Flange | A216 WCB | A350 LCB | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 12 | Stem packing | PTFE or Graphite | |||||

| 13 | Bonnet bolt | A193 B7 or A320 L7 or A320 B8 or A193 B8M | |||||

| 14 | Bonnet nut | A194 2H or A194 4 or A194 8 | |||||

|

Class 150 |

|||||||||||||

| DN | mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 |

| NPS | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| L(RF) | mm | 108 | 117 | 127 | 165 | 178 | 191 | 203 | 229 | 394 | 457 | 533 | 610 |

| in | 4.25 | 4.6 | 5 | 6.5 | 7 | 7.5 | 8 | 9 | 15.5 | 18 | 21 | 24 | |

| L1(BW) | mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | 559 | 635 |

| in | 5.5 | 6 | 6.5 | 7.48 | 8.5 | 9.5 | 11.13 | 12 | 18 | 20.5 | 22 | 25 | |

| L2(RTJ) | mm | 119 | 129.7 | 139.7 | 178 | 191 | 203 | 216 | 241 | 406 | 470 | 546 | 622 |

| in | 4.69 | 5.11 | 5.5 | 6.9 | 7.5 | 8 | 8.5 | 905 | 16 | 18.5 | 21.5 | 24.5 | |

| H | mm | 59 | 63 | 75 | 92 | 153 | 165 | 195 | 213 | 272 | 342 | 495 | 580 |

| in | 2.3 | 2.5 | 2.95 | 3.74 | 6.02 | 6.5 | 7.68 | 8.39 | 10.7 | 13.5 | 19.5 | 22.85 | |

| D(W) | mm | 130 | 130 | 160 | 230 | 400 | 400 | 600 | 850 | 1100 | 1500 | 350* | 350* |

| in | 5.1 | 5.1 | 6.3 | 9 | 15.74 | 15.74 | 23.62 | 33.46 | 43.3 | 59 | 13.8 | 13.8 | |

| Weight (Kg) | RF | 2.3 | 3 | 4.5 | 7 | 15 | 20 | 25 | 40 | 97 | 160 | 240 | 390 |

| BW | 2.0 | 2.5 | 3.8 | 5.8 | 12 | 17 | 21 | 36 | 92.8 | 154 | 227 | 365 | |

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.