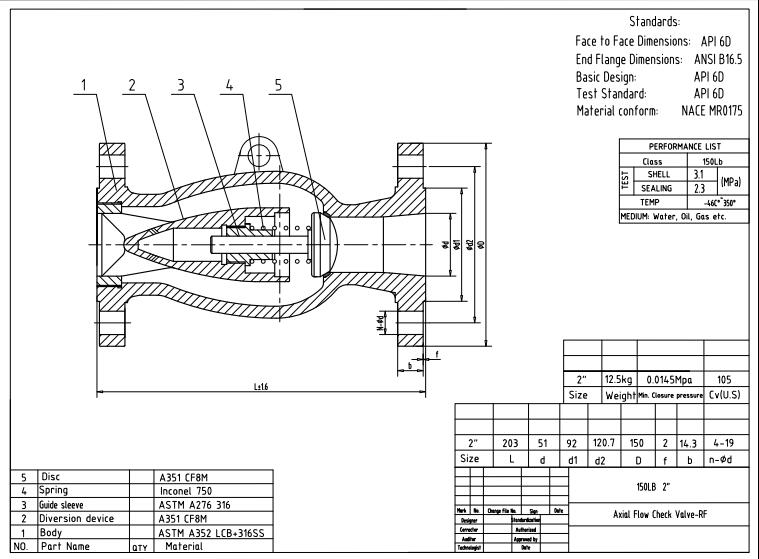

The 2inch axial nozzle check valve is the preferred solution for preventing return flow or shocks on critical process equipment. Thank for its LCB body, the valve is capable for working temperature down to -46 degree Celsius.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

LBCMethod of Operation:

NonQuick Detail

|

Type |

Check Valve |

|

Size |

2 Inch |

|

DesignPressure |

150LB |

|

Construction |

Axial Flow Type |

|

Connection |

RF |

|

Design & Manufacture |

API 6D |

|

End to End |

API 6D |

|

End Flange Dimensions |

ANSI B16.5 |

|

Test & Inspection |

API 6D |

|

Body Material |

LCB |

|

Trim Material |

SS316 |

|

Temp Range |

-46℃~350℃ |

|

Media |

W.O.G. |

Our nozzle check valve, characterized by an optimized flow profile and unique dual-spring design, solves common check valve operational issues while improving on the dynamic response and pressure loss of existing nozzle check valve designs.

Features

-Low pressure loss

-Unique dual-spring design for fast, dynamic, non-slam response

-Reliable, maintenance-free operation

Technical Drawing

Witness Tests

Nameplate&Packing

Why choose Dervos as your partner?

One Stop Service

Here in Dervos, we can provide you with one stop service by our complete product list, it means, you don’t need to search for various suppliers for different types of valves, and it will surely save your time and energy. All you need to do is choose Dervos and we will provide complete solutions to you.

On Time Delivery

Dervos keeps a high percentage of on time delivery. Why could we achieve that? Our purchasing team follows the order very closely. Plus, our QC and sales person will also do monitoring job on each order.

Strict Quality Control

All the members in the QC team are very experienced and professional. For each order, they will check the raw material, manufacturing process, do the pressure testing on shell and seal, and check the valve dimension per assembly drawing. Lastly, they will inspect the painting and packaging.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.