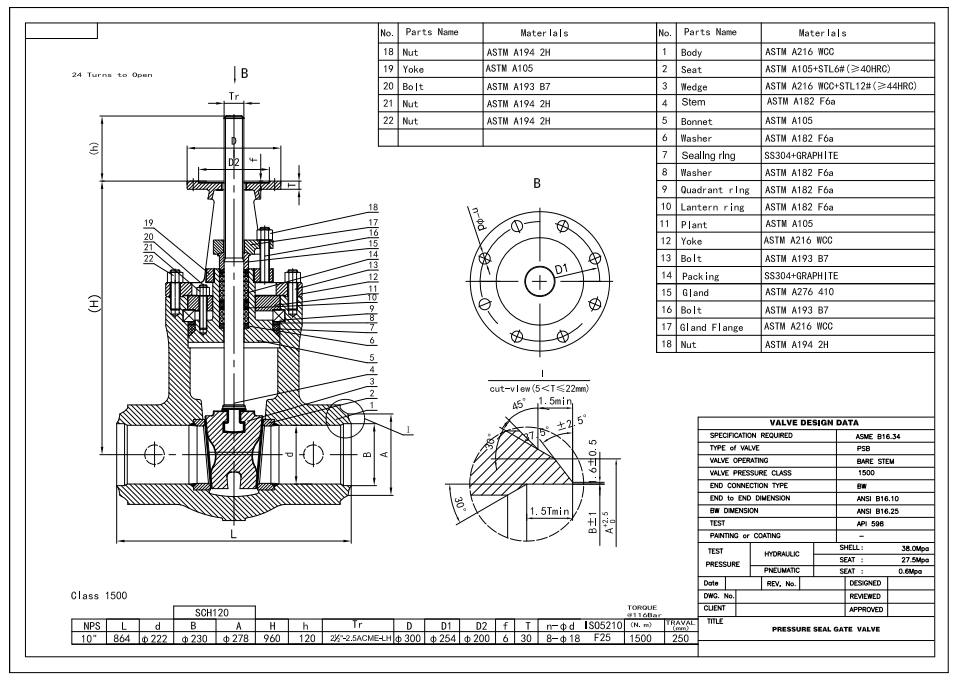

10'' 1500LB gate valve is made according to ASME B16.34 standard. The valve body is made of WCC. It has the structural characteristics of pressure self sealing, rising stem, elastic wedge and structural length of 864mm. Both ends of the valve stem are threaded. It has BW connection type.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

ASTM A216 WCCMethod of Operation:

Bare StemProduct Description

|

Type |

Gate Valve |

|

Size |

10'' |

|

Pressure |

1500LB |

|

Body Material |

ASTM A216 WCC |

|

Design Norm |

ASME B16.34 |

|

Type of Valve |

PSB |

|

Valve Operating |

Bare Stem |

|

End Connection Type |

BW |

|

End to End Dimension |

ANSI B16.10 |

|

BW Dimension |

ANSI B16.25 |

|

Test |

API 598 |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. Elastic wedge is adopted, which has certain elastic compensation under high pressure conditions, and the sealing is more reliable;

2. The sealing structure and sealing material can be selected according to different working conditions and preload requirements.

Technical Drawing

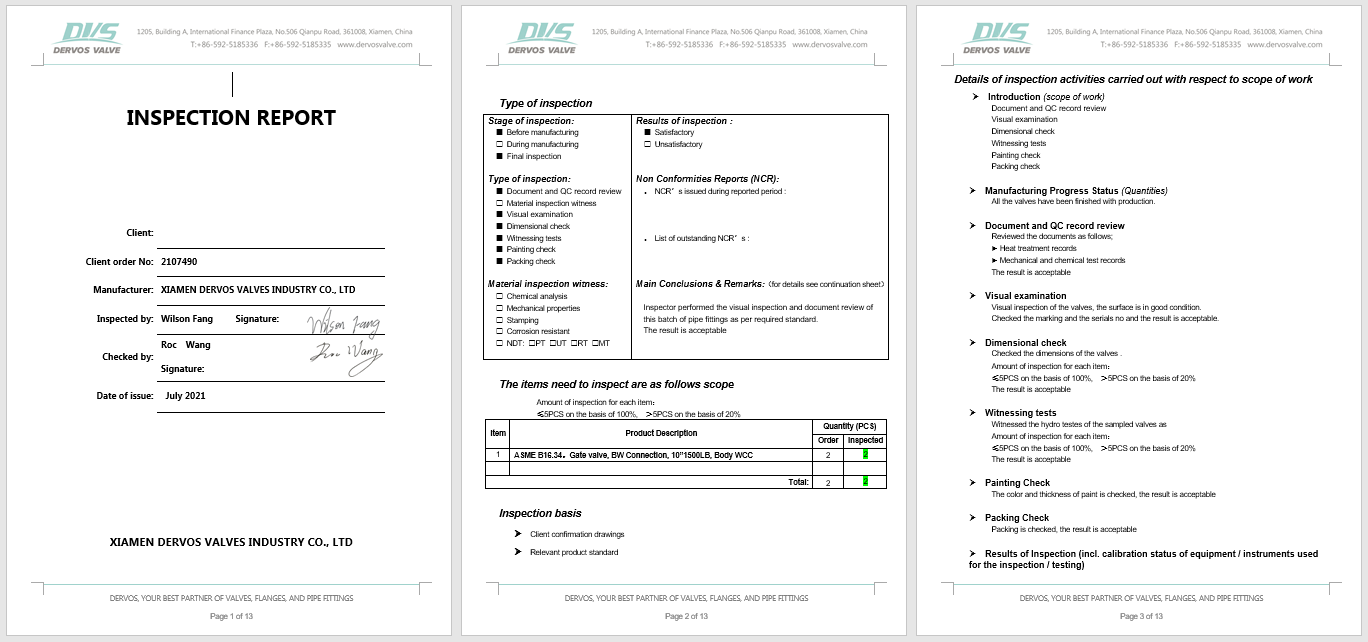

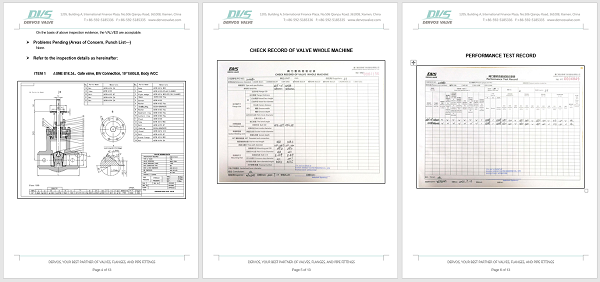

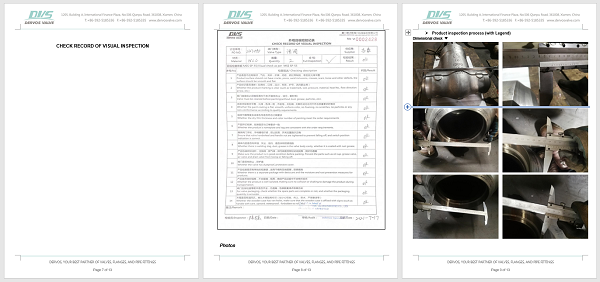

Dimension Checking

Witnessing Tests

Nameplate & Packing

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.