The gate valve is made of ductile iron GGG50 . The valves disc is rubber-packed to get excellent sealing effect by the rubber's resilient deformation. Non-rising resilient seated gate valves solve the problem in general gate valves such as leakage, rusting etc. And it also saves space.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

Ductile Iron GGG50Method of Operation:

handwheelQuick Detail

|

Type |

Gate Valve |

|

Nominal Diameter |

DN200 |

|

Nominal Pressure |

PN10 |

|

Construction |

Resilient Type; Non-rising Stem;B.B |

|

Connection |

RF |

|

Operation |

Handwheel |

|

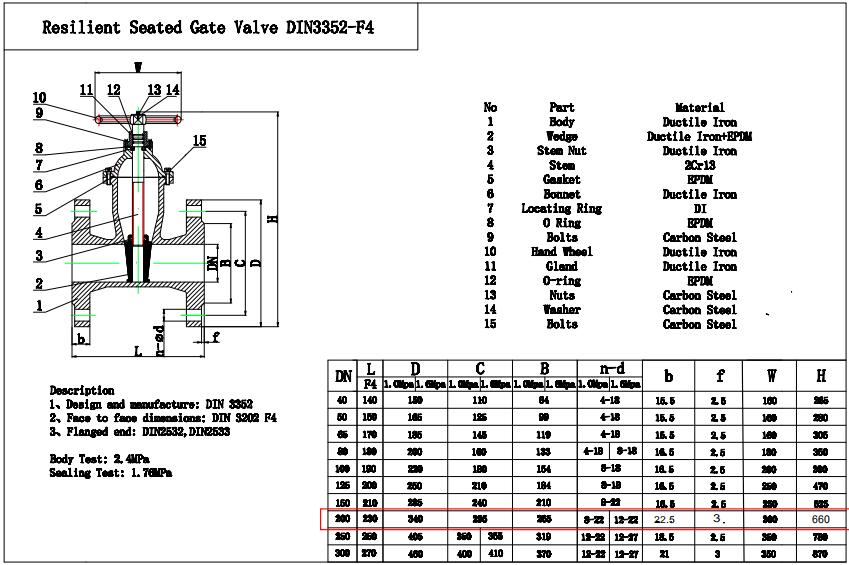

Design & Manufacture |

DIN 3352 |

|

End to End |

DIN 3202 |

|

Flange End Dimension |

DIN2532, DIN2533 |

|

Temperature Range |

-29℃~+425℃ |

|

Body Material |

GGG50 |

|

Wedge Material |

GGG50+EPDM |

|

Stem |

2Cr13 |

|

Media |

W.O.G. |

Technical Drawing

Painting &Packing

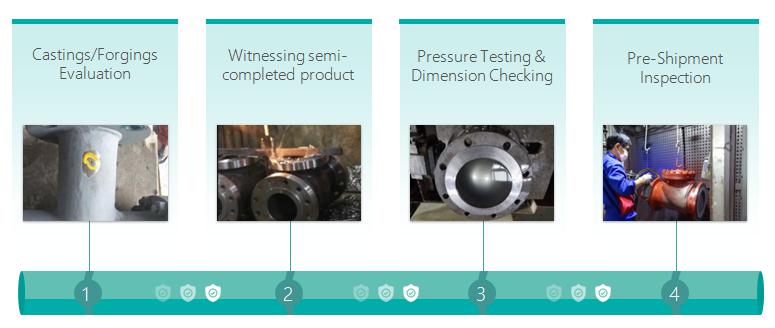

DVS Quality Checking

Quality means everything in Dervos. Quality checking team will do inspections according to standard procedure and provide reports. Our QC team will check valve quality from casting and forging, machining, pressure testing, dimension checking, painting & packing.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.