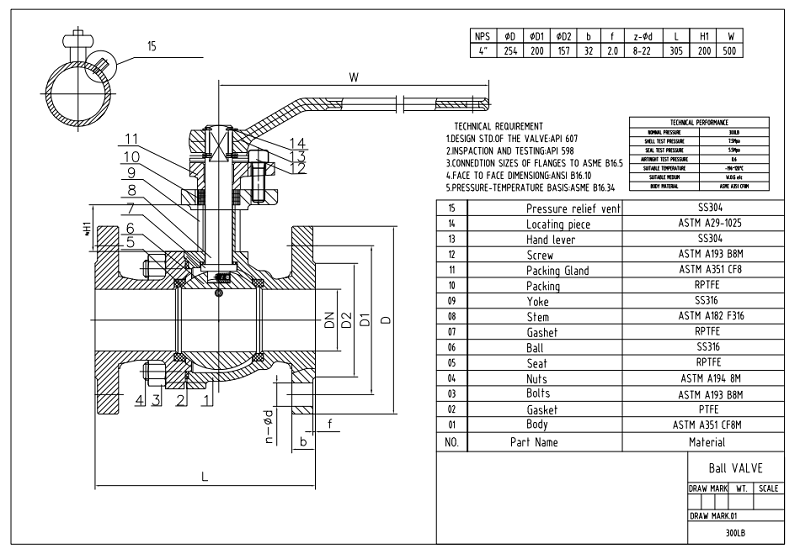

The 4 inch cryogenic ball valve, designed as per API609, has many parts equipped RPTFE --It has the lowest coefficient of friction and the best corrosion resistance of any known plastic material, so that the valve can handle quite extreme situations.

Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

F316Method of Operation:

LeverQuick Details

|

Type |

Ball Valve |

|

Nominal Diameter |

4" |

|

NominalPressure |

300LB |

|

Construction |

Bolted Weld, Extended Stem or Bonnet, Full Port |

|

Connection |

RF |

|

Operation |

Lever Operated |

|

Body Material |

F316 |

|

Design Code |

API 607 |

|

Pressure & Temp |

ASME B16.34 |

|

End toEnd Dimension |

ASME B16.10 |

|

Connection Size of Flanges |

ASME B16.5 |

|

Inspection |

API598 |

|

Temperature Range |

-196℃~+120℃ |

|

Media |

Oil, Water, Gas |

Design Feature

Extended stem and bonnet to position the stem packing above the cryogenic fluid and provide a column of warmer vapor that insulates the stem seal from the effects of low temperatures.

High-density seats and seals throughout the valve enable the valve to be rated down to -196°C service.

Vent hole is in the upstream face of the ball. This prevents the cold liquids from becoming trapped in the valve.

Stem primary seal and bearing are located near the packing end of the extended stem thus keeping these parts from the low temperatures and providing a blow-out proof stem design.

Valves are specially cleaned to remove all grease and oils that may react with the service media

Each valve after cleaning is packaged and sealed in a heavy poly bag to keep the valve clean until installation.

Technical Drawing

Our Service

Dervos customer service is one of our biggest competitive advantages. In Dervos, we provide-

1. Quotation within 24 hours or no later than 3 days

This will let you meet the quotation submission deadline and enhance your working efficiency

2. Weekly status report of your order

In this way, you will have a clear picture of your order. You do not need to waste time on pushing us for status update

3. An 18-month warranty period

A warranty certificate will issued after shipment and you will not have any concern after buying valves.

4. Solutions to complaints within 3 days

Quick and responsible actions to complaints will protect your reputation and reduce the financial loss as much as possible.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.