China 1 Inch Gate, Valve Manufacturer Dervos Provides 1 Inch Gate Valve, A105, API 600, Class 600, Flanged, Handwheel Operation.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

Forging Steel A105Method of Operation:

HandwheelQuick Detail

|

Type |

Gate Valve |

|

Nominal Diameter |

1 Inch |

|

Nominal Pressure |

600LB |

|

Construction |

B.B ; OS&Y; Solid Wedge; Reduced Bore |

|

Connection |

Flange |

|

Operation |

Handwheel |

|

Design & Manufacture |

API600/ ASME B16.34 |

|

End to End |

ASME B16.10 |

|

Flange End Dimension |

ASME B16.5 |

|

Test & Inspection |

API598 |

|

Body Material |

A105 |

|

Wedge Material |

F316 |

|

Media |

W.O.G. |

Features

- Bolted Bonnet:valve body and bonnet are bolted and flanged together.

- Rising Stem:larger structure requires more space and long-time opening.

- Solid Wedge:solid design also minimized the vibration and chatter.

- Reduced Port:also standard port.

- Renewable Seat: convenient for maintenance.

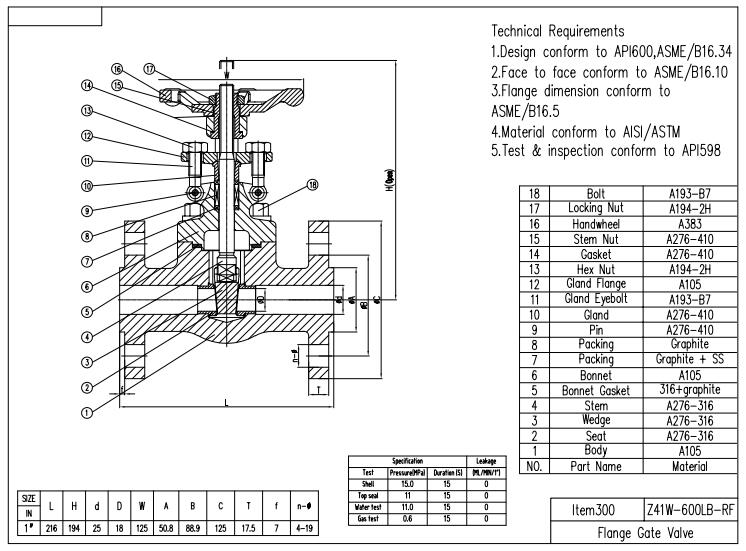

Technical Drawing

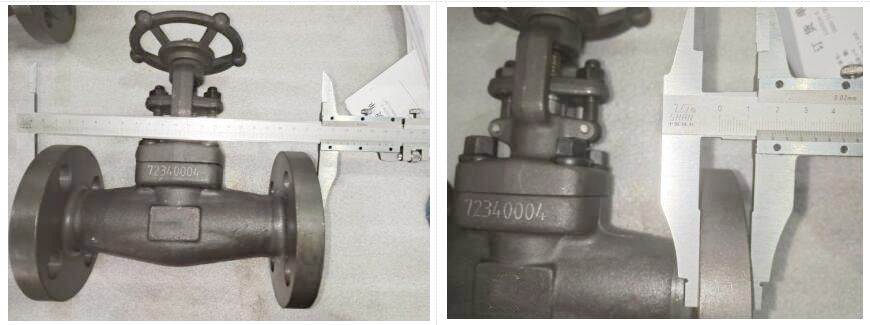

Dimension Check

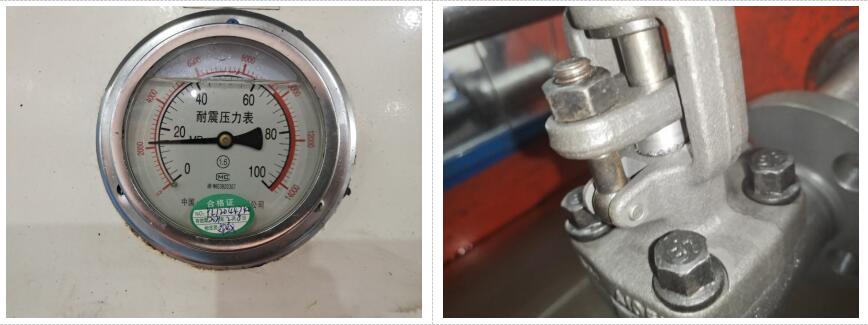

Witnessing Tests

About Dervos

Specializing in valve industry over 10 years, Dervos becomes the leading vendor of gate, globe, check, ball, butterfly, plug valves and strainers. We serve oil and gas user such as LUKOIL, MOL, YPF with local partners.

Dervos show its advantages in:

1. Our partnerships with tens of stable suppliers allow us to provide customers with a wide range of high-quality products at a competitive price.

2. Each order is under strict quality control with inspection reports before delivery.

3. We value delivery time as much as our customers do. With the powerful purchasing system, we follow each order closely to secure on-time delivery.

4. One-stop solutions will be offered in a timely manner

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.