Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai ChinaLead Time:

35~60 days Ex Works After Order ConfirmationMaterial:

Carbon Steel Plug Valve, Cast Steel Plug Valve, WCCMethod of Operation:

Gear Operated Plug ValveQuick Detail

|

Type |

Plug Valve |

|

Size |

8'' |

|

Design Pressure |

300LB |

|

Construction |

Lubricated Type, Inverted Type, Pressure Balanced Type, Metal Seated |

|

Connection Type |

Flanged Connection |

|

Operation |

Gear Operated |

|

Design Code |

API 599 |

|

Face to Face |

ASME B16.10 |

|

End Connection |

ASME B16.5 |

|

Pressure & Temp |

ASME B16.34 |

|

Test & Inspection |

API 598 |

|

Body Material |

WCC |

|

Temperature Range |

-29℃~+425℃ |

|

Application |

Water, Oil, Gas |

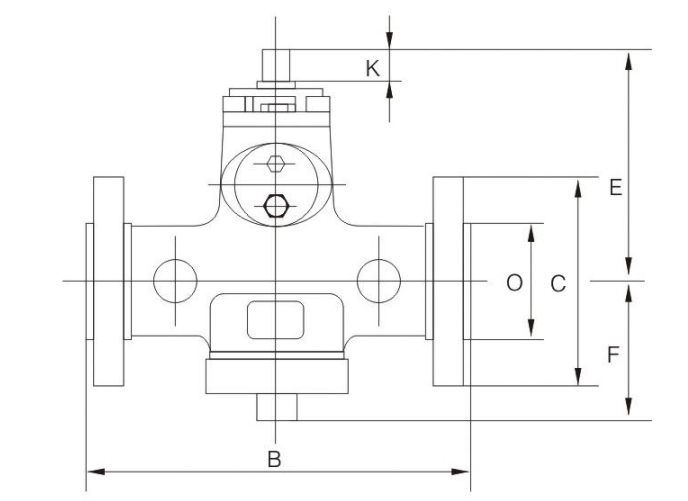

Dimension

| Class | Size | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| 300 | B | 191 | 216 | 241 | 283 | 305 | 403 | 419 | 457 | 502 |

| C | 156 | 165 | 191 | 210 | 254 | 318 | 381 | 445 | 521 | |

| D | 20.6 | 22.2 | 25.4 | 28.3 | 31.8 | 36.5 | 41.3 | 47.6 | 50.8 | |

| E | 169 | 178 | 219 | 235 | 362 | |||||

| F | 106 | 118 | 143 | 165 | 187 | 248 | 300 | 392 | ||

| O | 73 | 92.1 | 105 | 127 | 157 | 216 | 270 | 324 | 381 | |

| Weight(RF) | 16 | 21 | 38 | 60 | 101 | 192 | 281 | 508 |

Related Knowledge

What is a plug valve?

Plug valve is a quater-turn valve whose plug rotates around the centerline of valve body to realize on-off function. The plug valve is used for cutting off, distributing and changing the flow directoin. Currently, plug valves are mainly applicable for small size, normal temperature, and low pressure conditions.

The advantages of plug valve are shown below:

-Quick opening and closing the valve

-Small fluid resistance

-Reliable leak-tight service

-Available inline maintenance

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.