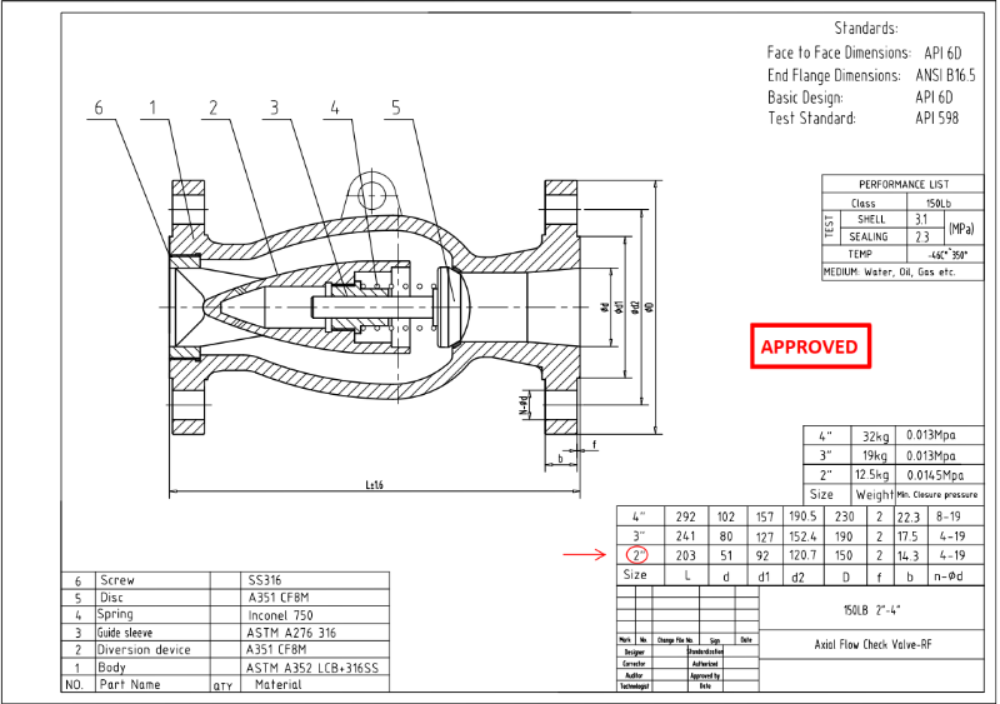

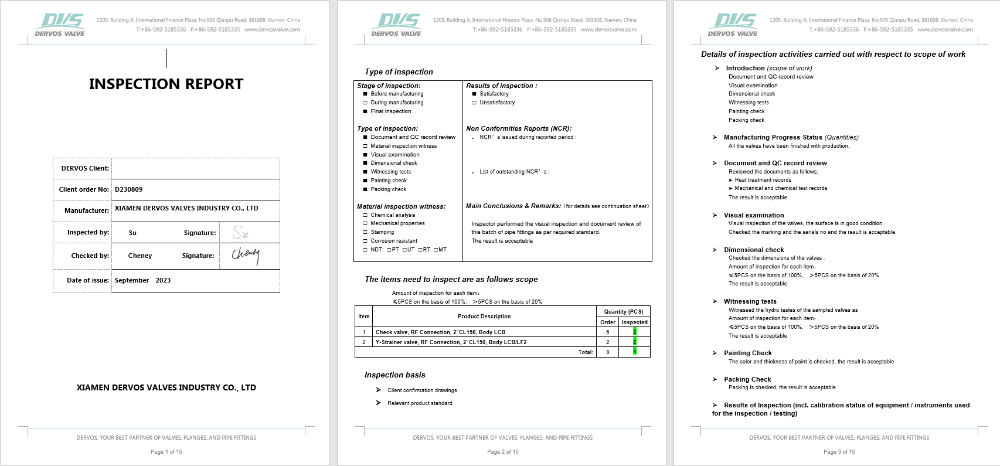

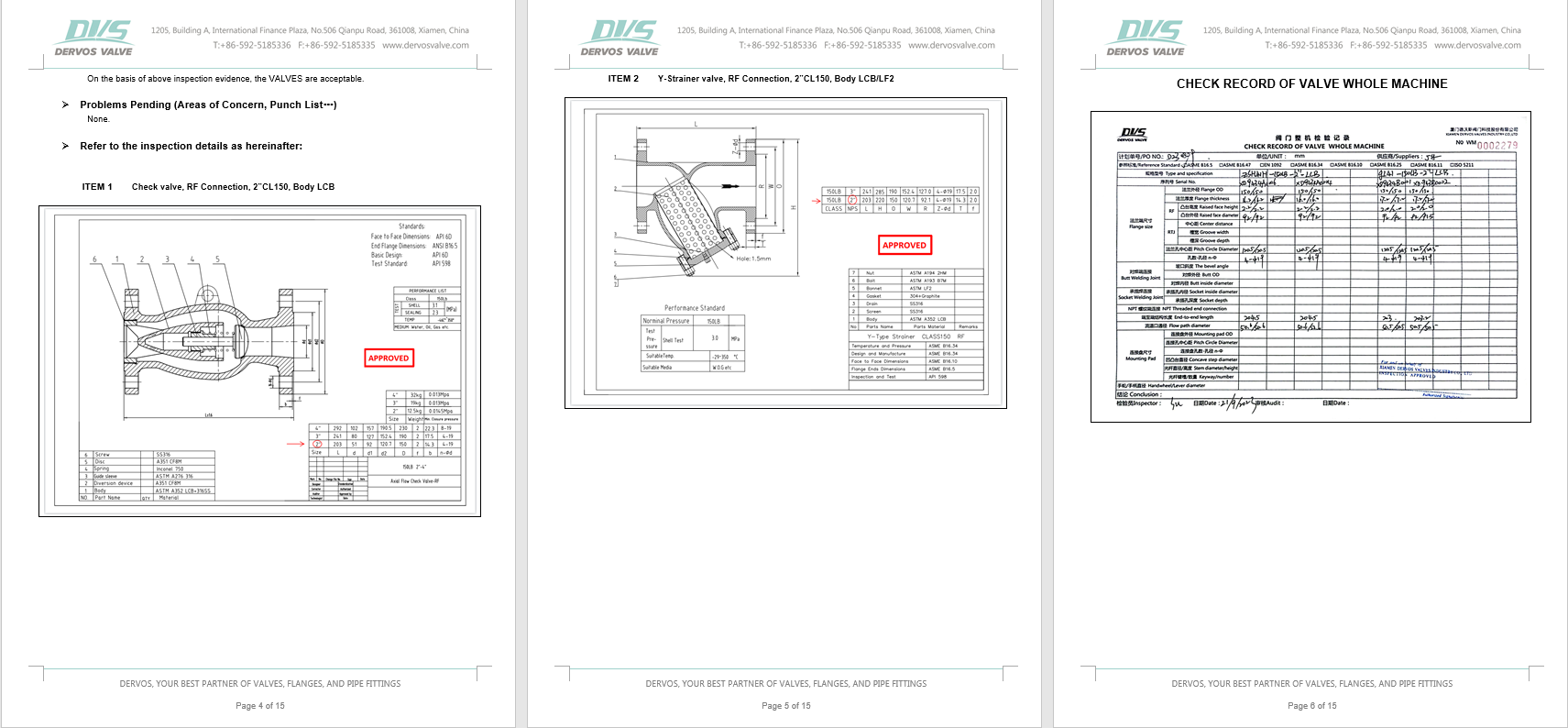

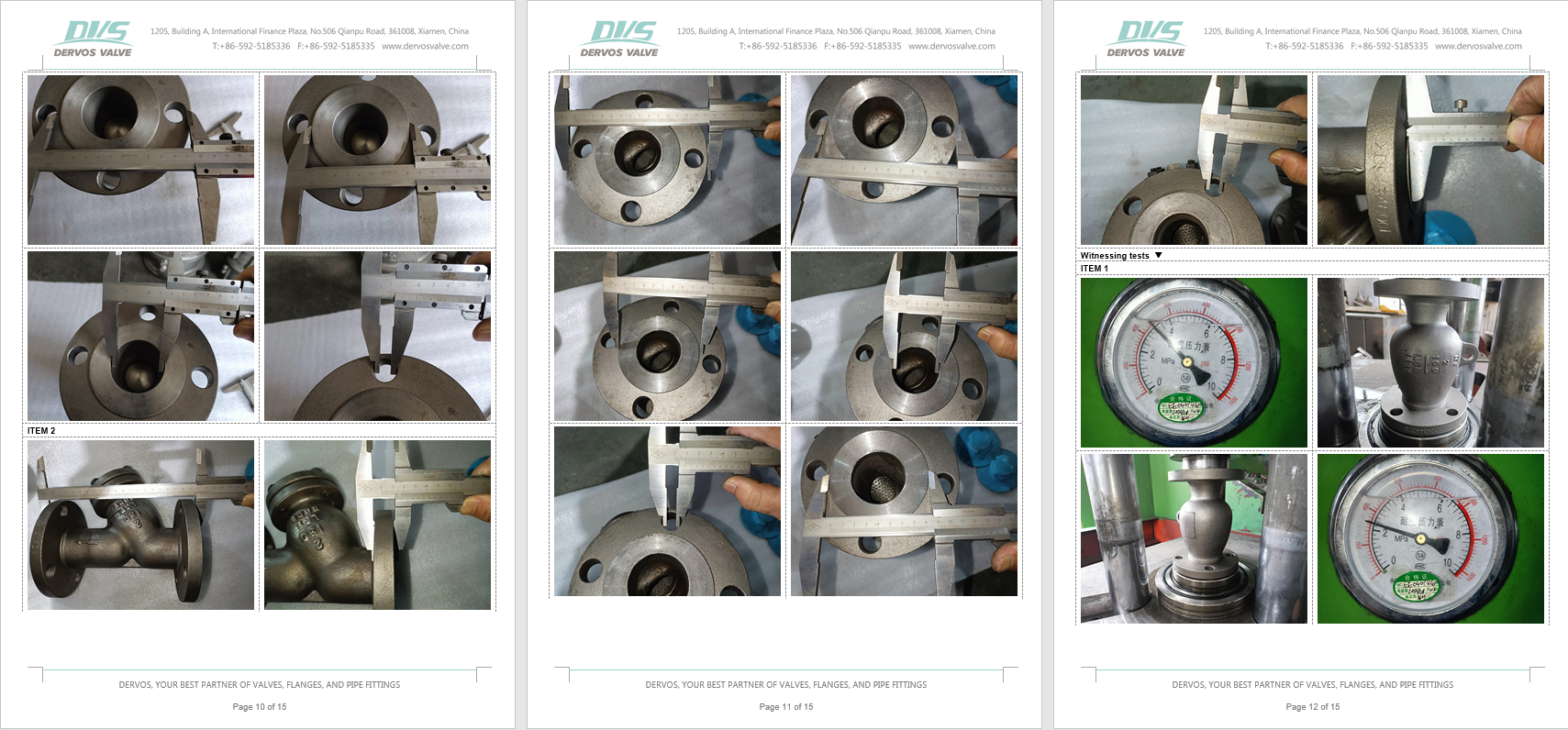

2”CL150 Axial Flow Check Valve is made according to API 6D standard. The valve body is made of ASTM A352 LCB+316SS. It has the structural characteristics of axial flow. Its connection mode is RF.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

chinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

ASTM A352 LCB+316SSMethod of Operation:

H.W.

|

Type |

Axial Flow Check Valve |

|

Size |

2” |

|

Pressure |

CL150 |

|

Connection |

RF |

|

Body Material |

ASTM A352 LCB+316SS |

|

Design Norm |

API 6D |

|

Face to Face |

API 6D |

|

End Flange Dimensions |

ASME B16.5 |

|

Test & Inspection Code |

API 598 |

|

Temperature |

-46 ~ 350°C |

|

Applicable Medium |

Water, Oil and Gas |

1. Axial flow design minimizes pressure drop and ensures smooth, low-turbulence flow.

2. Manufactured to API 6D standard with RF ends, providing reliable backflow prevention in pipeline systems.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.