Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai ChinaLead Time:

35~60 days Ex Works After Order ConfirmationMaterial:

Alloy Steel Gate Valve WC6Method of Operation:

Gear Operated Gate ValveThe 8 inch Class 2500 gate valve is designed with pressure seal bonnet, butt weld connection, and gearbox operation. The 8 inch gate valve has carbon steel WCB body and trim 5.

Quick Detail

|

Type |

Gate Valve |

|

Size |

8'' |

|

Design Pressure |

ANSI 2500 |

|

Construction |

Pressure Seal Bonnet, Flexible Wedge, Metal to Metal Seat |

|

ConnectionType |

Butt Weld (SW) |

|

OperationType |

Gearbox Operation |

|

Body Material |

A217 WC6 |

|

TrimMaterial |

Trim 5 |

|

Design Code |

API 600 |

|

Face to Face Dimension |

ASME B16.10 |

|

End Connection |

ASME B16.25 |

|

Pressure & Temp |

ASME B16.34 |

|

Medium |

Water, Oil and Gas |

|

Origin |

China |

Dimension & Material

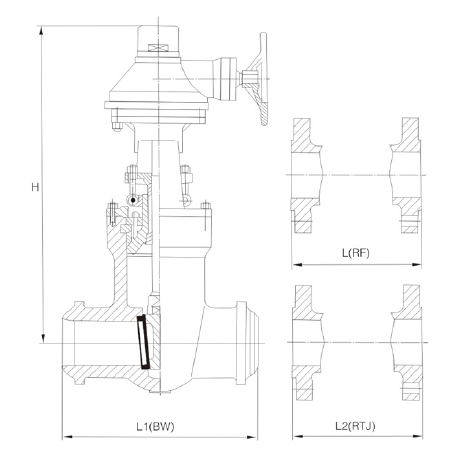

| NPS DN | Class | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | ||

| L(RF) | 900LB | 368 | 419 | 381 | 457 | 610 | 737 | 838 | 965 | 1029 | 1130 | |||

| 1500LB | 368 | 419 | 470 | 546 | 705 | 832 | 991 | 1130 | 1257 | 1384 | ||||

| 2500LB | 451 | 508 | 578 | 673 | 917 | 1022 | 1270 | |||||||

| L1(BW) | 900LB | 216 | 254 | 305 | 355 | 508 | 660 | 787 | 914 | 991 | 1092 | 1346 | 1473 | 1600 |

| 1500LB | 216 | 254 | 305 | 406 | 559 | 711 | 864 | 991 | 1067 | 1194 | 1697 | |||

| 2500LB | 279 | 330 | 368 | 457 | 610 | 762 | 914 | 1041 | 1118 | 1245 | ||||

| L2(RTJ) | 900LB | 371 | 422 | 384 | 460 | 613 | 740 | 841 | 968 | 1038 | 1140 | |||

| 1500LB | 371 | 422 | 473 | 549 | 711 | 841 | 1000 | 1146 | 1276 | 1407 | ||||

| 2500LB | 454 | 514 | 584 | 683 | 927 | 1038 | 1292 | |||||||

| H(Opne) | 900LB | 554 | 637 | 680 | 796 | 1084 | 1372 | 1494 | 1550 | 1960 | 2210 | |||

| 1500LB | 554 | 637 | 767 | 875 | 1094 | 1372 | 1655 | 1834 | 2150 | 2260 | 2460 | 2721 | 2940 | |

| 2500LB | 610 | 654 | 753 | 850 | 1254 | 1374 | 1685 | 1894 | 2226 | 2382 | 2585 | |||

| W | 900LB | 300 | 350 | 350 | 400 | 560 | 460* | 610* | 610* | 610* | 760* | |||

| 1500LB | 300 | 450 | 450 | 560 | 305* | 460* | 610* | 610* | 760* | 760* | ||||

| 2500LB | 500 | 500 | 600 | 600 | 460* | 460* | 610* | |||||||

| Weight (RF) | 900LB | 50 | 84 | 92 | 154 | 341 | 622 | 950 | 1295 | 1720 | 2380 | |||

| 1500LB | 60 | 91 | 128 | 182 | 394 | 795 | 1370 | 2120 | 2800 | 3870 | ||||

| 2500LB | 121 | 175 | 195 | 229 | 720 | 1295 | 2250 | |||||||

| Weight (BW) | 900LB | 39 | 64 | 82 | 120 | 266 | 524 | 760 | 1090 | 1450 | 2018 | |||

| 1500LB | 46 | 71 | 85 | 130 | 292 | 578 | 974 | 1615 | 2010 | 2815 | 3315 | 4150 | 5219 | |

| 2500LB | 88 | 135 | 144 | 158 | 500 | 892 | 1550 | 1978 | 2580 | 3780 | 5988 | |||

| *Manual gear operator is recommended | ||||||||||||||

| No. | Part | WCB | WC6 | WC9 | C5 | CF8 | CF8M |

| 1 | Body | A216 WCB | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M |

| 2 | Seat | A182 F6a | A182 F22 | A182 F22 | A182 F5 | A182 F304 | A182 F316 |

| 3 | Wedge | A216 WCB | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M |

| 4 | Stem | A182 F6a | SAEHNV3 | A182 F304 | A182 F316 | ||

| 5 | Stuffing Box | A216 WCB | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M |

| 6 | Seal Ring | ANSI 316L | Flexible Graphite+316 | ||||

| 7 | Split Ring | Steel | F6 | F6 | F6 | A182 F304 | F316 |

| 8 | Back Ring | Steel | Steel | Steel | Steel | SS | SS |

| 9 | Bolt | A193 B7 | A193 B7 | A193 B7 | A193 B7 | A193 B8 | A193 B8 |

| 10 | Nut | A194 2H | A194 2H | A194 2H | A194 2H | A194 Gr.8 | A194 Gr.8 |

| 11 | Yoke | A216 WCB | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M |

| 12 | Bolt | A193 B7 | A193 B7 | A193 B7 | A193 B7 | A193 B8 | A193 B8 |

| 13 | Nut | A194 2H | A194 2H | A194 2H | A194 2H | A194 Gr.8 | A194 Gr.8 |

| 14 | Packing Plate | ANSI 410 | ANSI 410 | ANSI 410 | ANSI 410 | ANSI 304 | ANSI 316 |

| 15 | Packing | Flexible Graphite(Braided and Ring) or PTFE | |||||

| 16 | Split Pin | Steel | Steel | Steel | Steel | Steel | Steel |

| 17 | Eyebolt | A193 B7 | A193 B7 | A193 B7 | A193 B7 | A193 B8 | A193 B8 |

| 18 | Gland | A182 F6 | A182 F6 | A182 F6 | A182 F6 | A182 F304 | A182 F316 |

| 19 | Gland Flange | A105 | A105 | A105 | A105 | A182 F304 | A182 F316 |

| 20 | Nut | A194 2H | A194 2H | A194 2H | A194 2H | A194 Gr.8 | A194 Gr.8 |

| 21 | Stud | A193 B7 | A193 B7 | A193 B7 | A193 B7 | A193 B7 | A193 B7 |

| 22 | Stem Nut | Ni-resist A439-D2 | |||||

| 23 | Gear Box | Purchased | |||||

| 24 | Protector | Steel | |||||

| 25 | Nameplate | ANSI 304 | |||||

| 26 | Rivet | ANSI 304 | |||||

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.