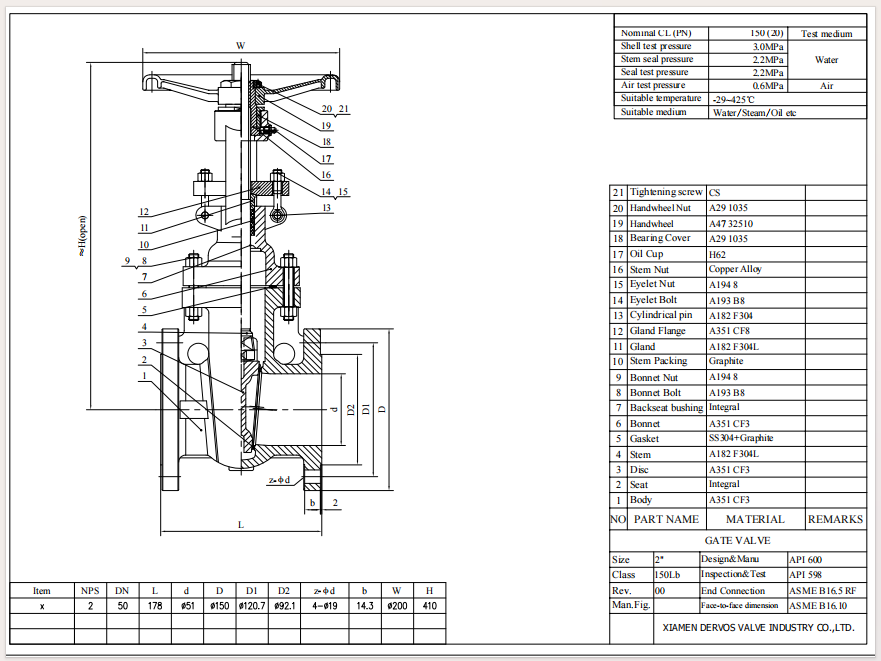

2" 150LB gate valve is made according to API 600 standard. The valve body is made of A351 CF3. It has the structural characteristics of bolt cover, rising stem bracket. Its connection mode is RF. And it has handwheel operation mode.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A351 CF3Method of Operation:

HandwheelProduct Description

|

Type |

Gate Valve |

|

Size |

2" |

|

Pressure |

150LB |

|

Connection |

RF |

|

Operation |

Handwheel |

|

Body Material |

A351 CF3 |

|

Design Norm |

API 600 |

|

Face to Face Dimension |

ASME B16.10 |

|

End Connection |

ASME B16.5 RF |

|

Test & Inspection Code |

API 598 |

|

Temperature |

-29 ~ 425 °C |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. Compact structure, simple structure, compact appearance, easy assembly, and reliable operation;

2. Flexible switch, easy to open and close operation.

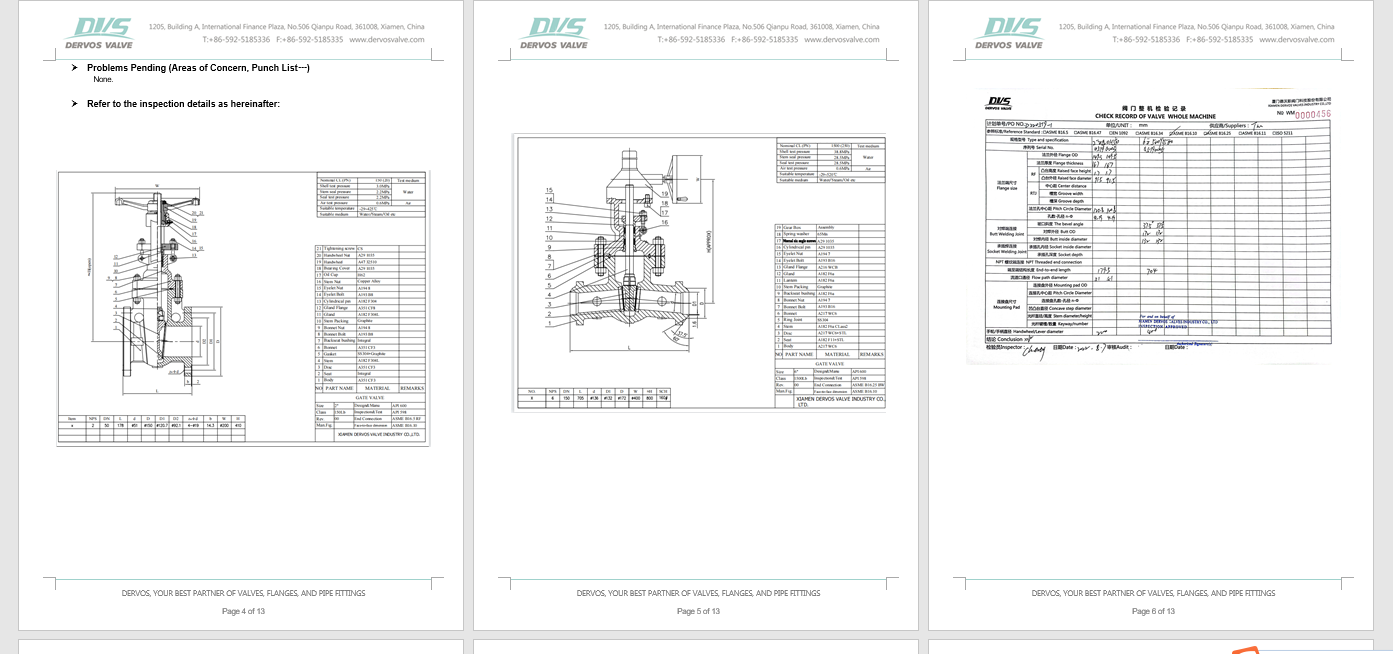

Technical Drawing

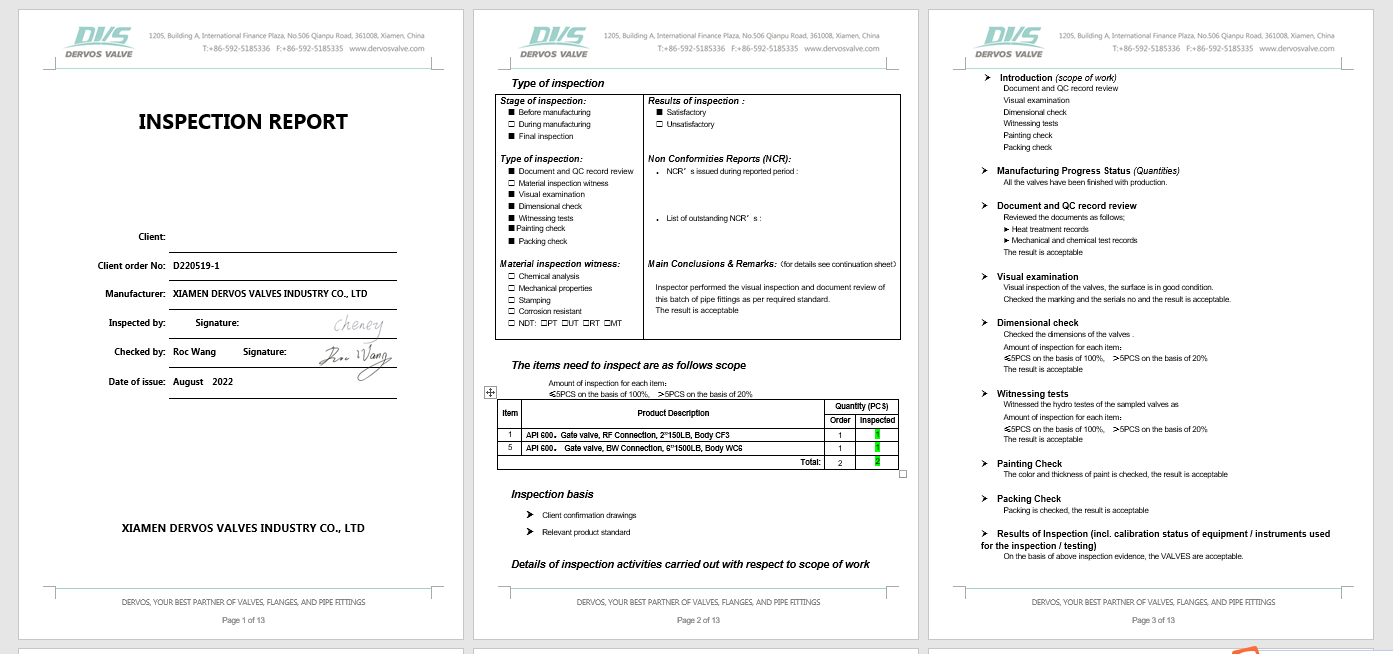

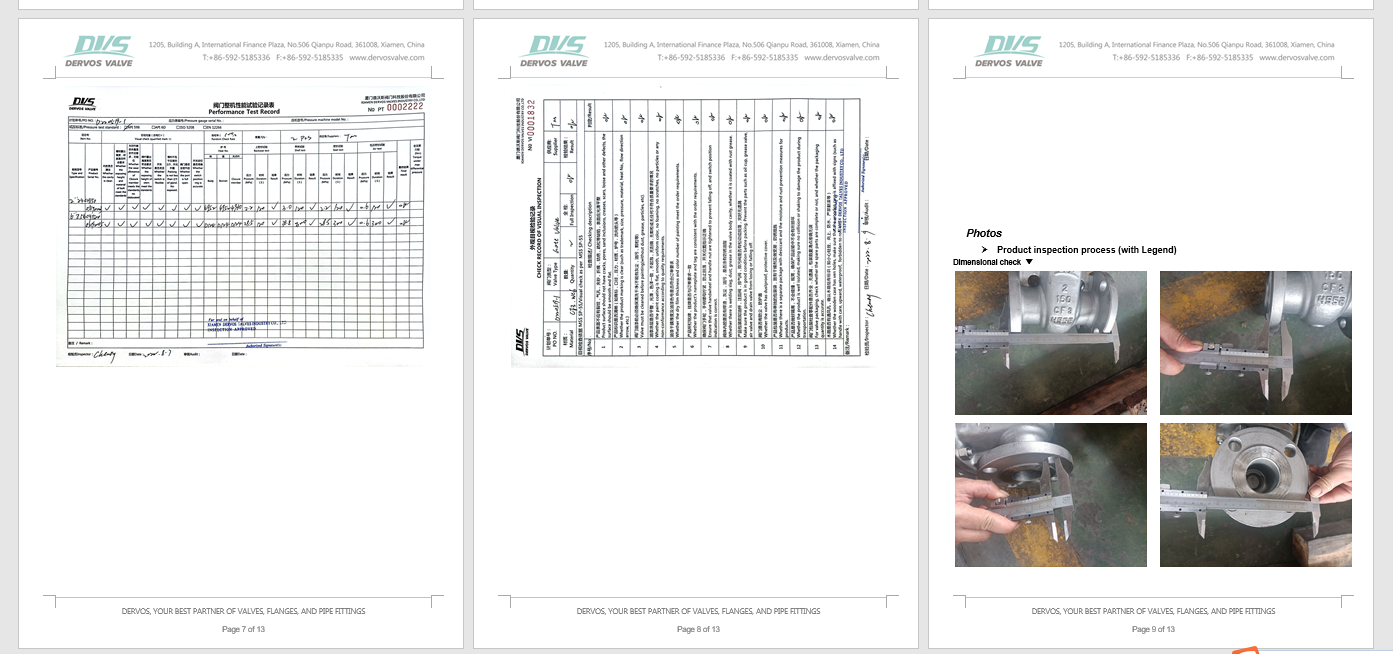

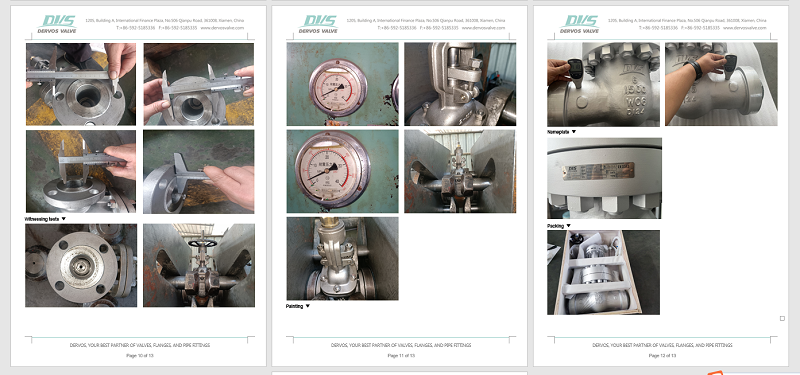

Dimension Checking

Pressure Testing

Nameplate & Packing

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.