This 20 inch butterfly valve is plastic lined type one. Its PFA lined disc and its PTFE seat ring enable it a excellent corrosion resistant performance. With a gearbox, it is easy to drive.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A216 WCBMethod of Operation:

GearboxQuick Detail

|

Type |

Butterfly Valve |

|

Nominal Diameter |

20' |

|

Nominal Pressure |

150LB |

|

Construction |

Flat Flange |

|

Connection |

Lug Type; |

|

Operation |

Gearbox |

|

Design & Manufacture |

API609 |

|

End to End Dimension |

ASME B16.10 |

|

Flange Dimension |

ASME B16.5 |

|

Body Material |

A216 WCB |

|

Disc Material |

SS2205+PFA |

|

Media |

W.O.G |

Features

--Substantial PFA liners for 3" through 12" and PTFE liners for 14" through 24"

Well resistance to permeation leading to extension of product life and operator safety

--Low torque. Smaller operators taking up less space, ease of operation and cost savings with less expensive automation packages.

--Improved disc design leads to less deflection at higher pressures and tighter in-line seal.

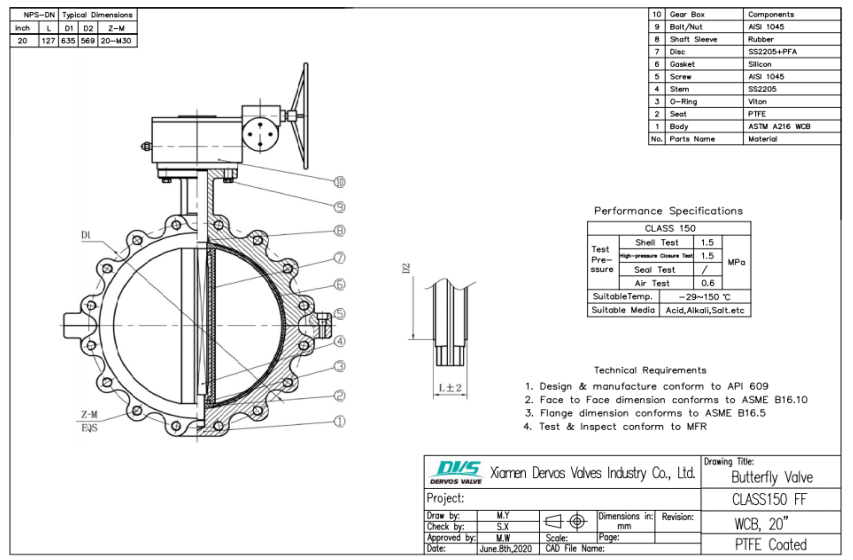

Technical Drawing

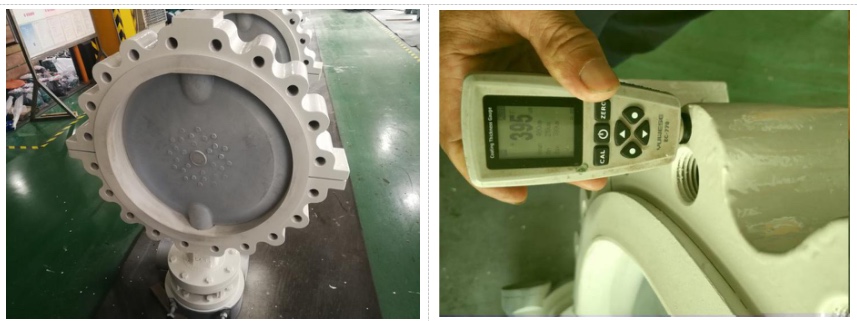

Painting Check

Packing

Our Main Product Range

As an experienced supplier and vendor of industrial valves, Dervos supply cast steel valve, forged steel valve, cast iron valve, stainless steel valve, bronze valve, brass valve and alloy steel valve and so on, suitable for sea water, water, oil, and gas application.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.