6" 150LB Y type strainer is made according to ASME B16.34 standard. The valve body is made of ASTM A995 4A. It has the structural characteristics of Y-shaped, bolted cover, MESH 40, with integral drain plug. Its connection mode is RF.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

ASTM A995 4AProduct Description

|

Type |

Y Type Strainer |

|

Size |

6" |

|

Pressure |

150LB |

|

Connection |

RF |

|

Body Material |

ASTM A995 4A |

|

Design Norm |

ASME B16.34 |

|

Face to Face Dimension |

ASME B16.10 |

|

Flange Dimension |

ASME B16.5 |

|

Comply |

NACE MR-0175 |

|

Marking |

MSS-SP-25 |

|

Test & Inspection Code |

API 598 |

|

Temperature |

-29 ~ 315°C |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. Simple design, compact structure, small volume, easy to manufacture and maintain;

2. The filter is easy to disassemble and clean, with simple maintenance, reducing maintenance workload and downtime.

Technical Drawing

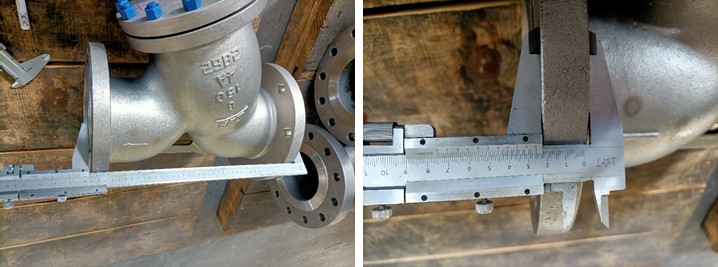

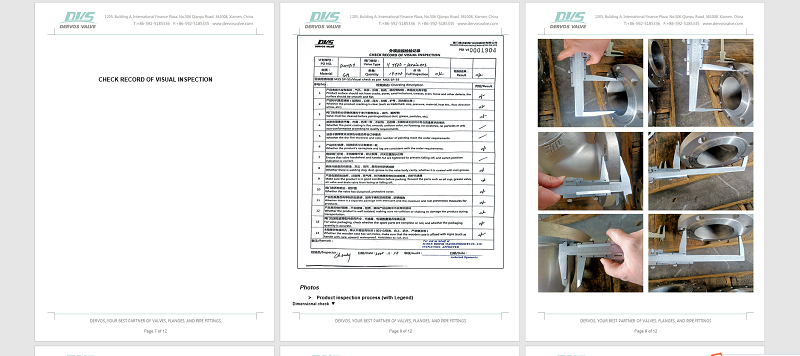

Dimension Checking

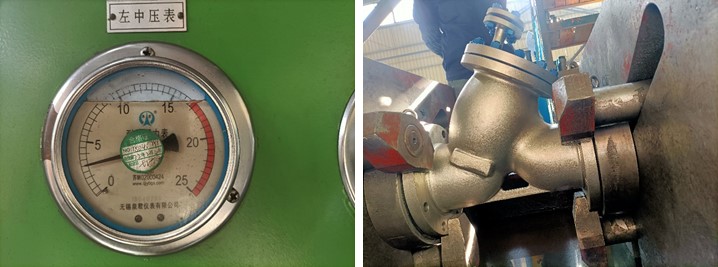

Pressure Testing

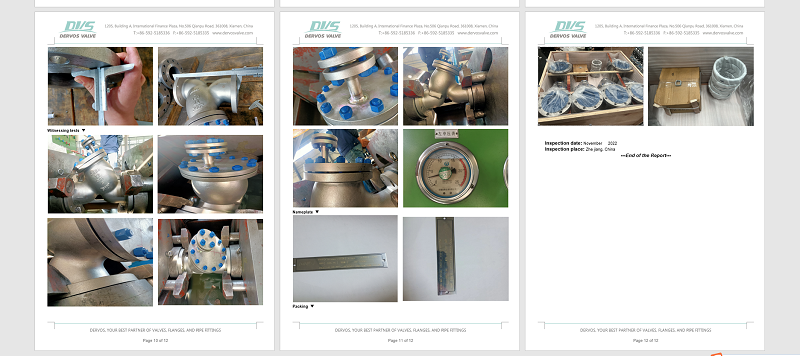

Nameplate & Packing

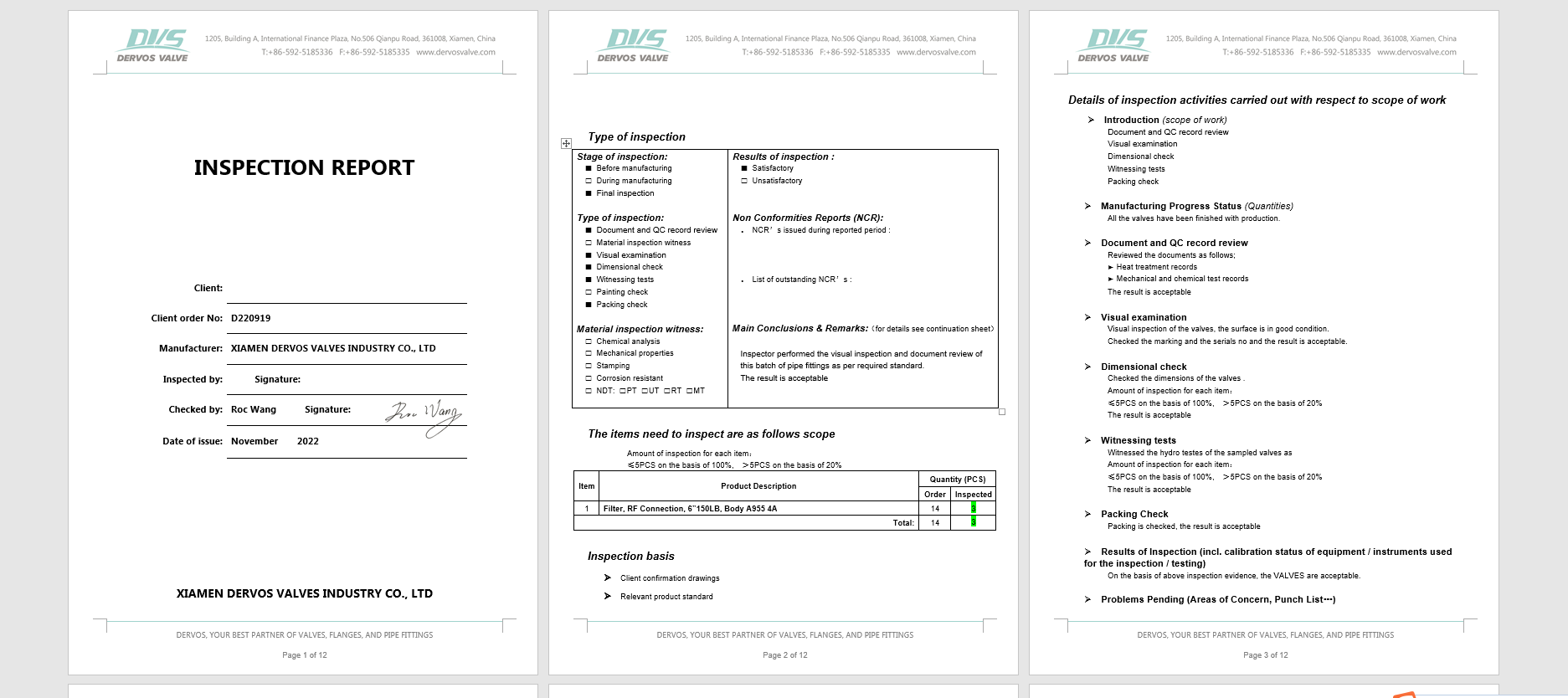

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.