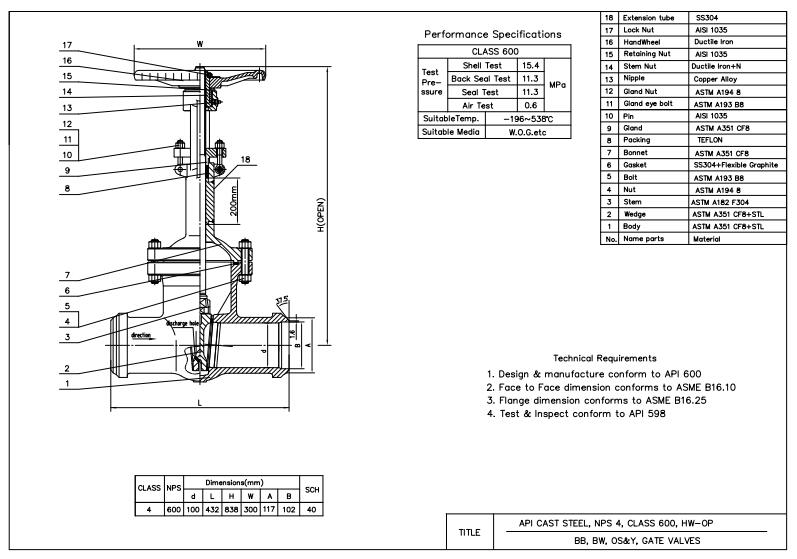

The gate valve, made according to API 600, is made of CF8, one kind of cast steel. The 4 inch valve is equipped a handwheel, outside yoke, bolted bonnet and extended bonnet. All the accessories are traceable.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

CF8Method of Operation:

Handwheel

Quick Details

|

Type |

Gate Valve |

|

Size |

4 Inch |

|

Design Pressure |

600LB |

|

Construction |

B.B; OS&Y; Extended Bonnet |

|

Connection Type |

Bolt Welded |

|

Operation Type |

Handwheel |

|

Body Material |

CF8 |

|

Disc Material |

CF8+STL |

|

Design Code |

API 600 |

|

Flange Ends |

ASME B16.25 |

|

Face to Face |

ASME B16.10 |

|

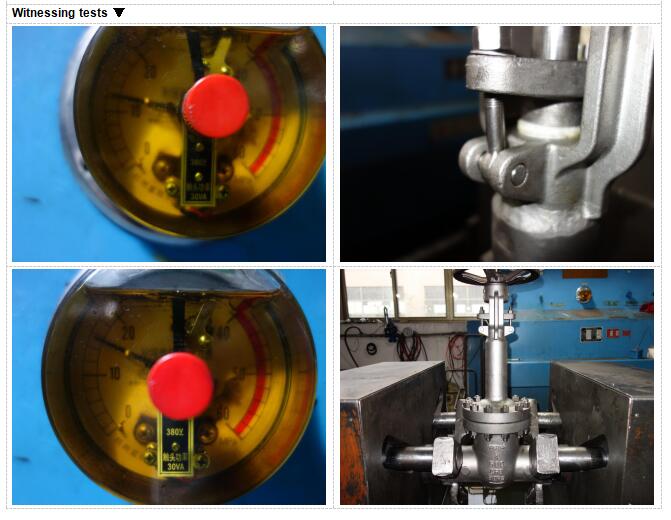

Inspection and Test |

API 598 |

|

Temperature |

-196~539℃ |

|

Medium |

Water, Oil and Gas |

|

Origin |

China |

Features

-Full Bore Design

-Superior flow rates & small friction loss

-Low torque value for closing and opening the valve

-Flexible wedge for better seating and easy operation

-Smooth finish and superior sealing for seat face

-Every valve is manufactured with specific number on body for traceability

Technical Drawing

Our Service

Dervos customer service is one of our biggest competitive advantages. In Dervos, we provide-

1.Quotation within 24 hours or no later than 3 days

This will let you meet the quotation submission deadline and enhance your working efficiency

2.Weekly status report of your order

In this way, you will have a clear picture of your order. You do not need to waste time on pushing us for status update

3.An 18-month warranty period

A warranty certificate will issued after shipment and you will not have any concern after buying valves.

4.Solutions to complaints within 3 days

Quick and responsible actions to complaints will protect your reputation and reduce the financial loss as much as possible.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.