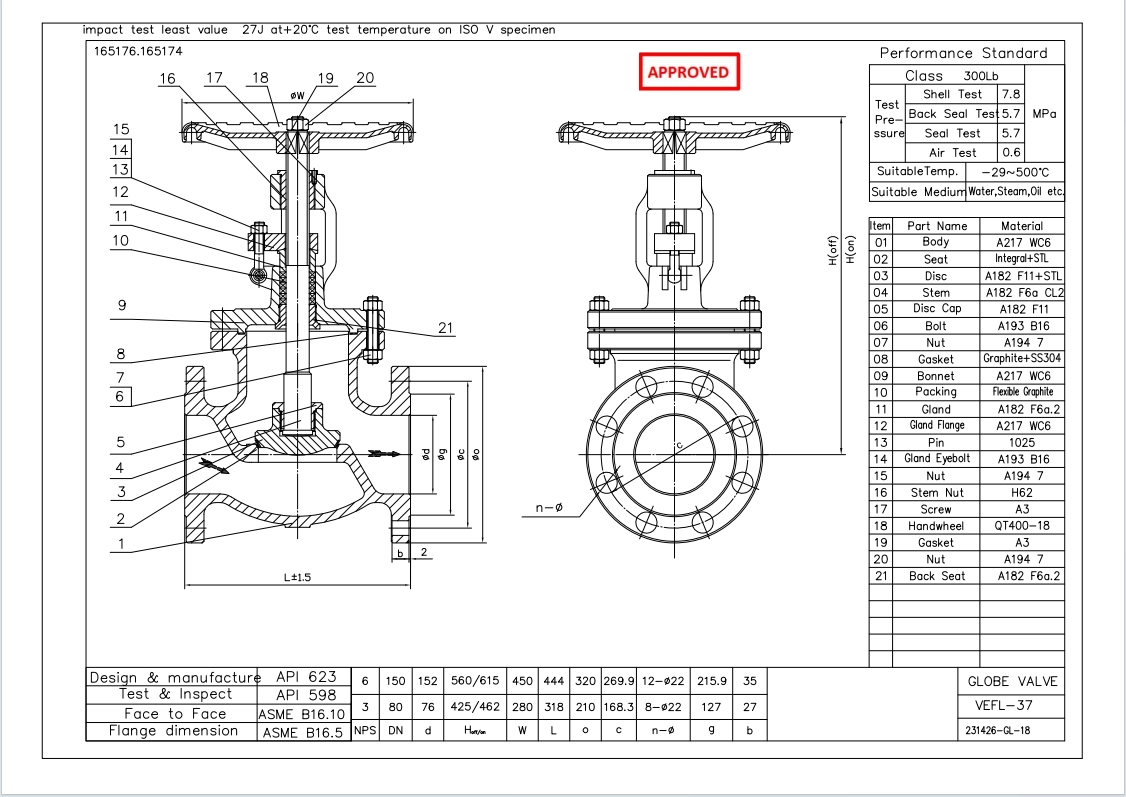

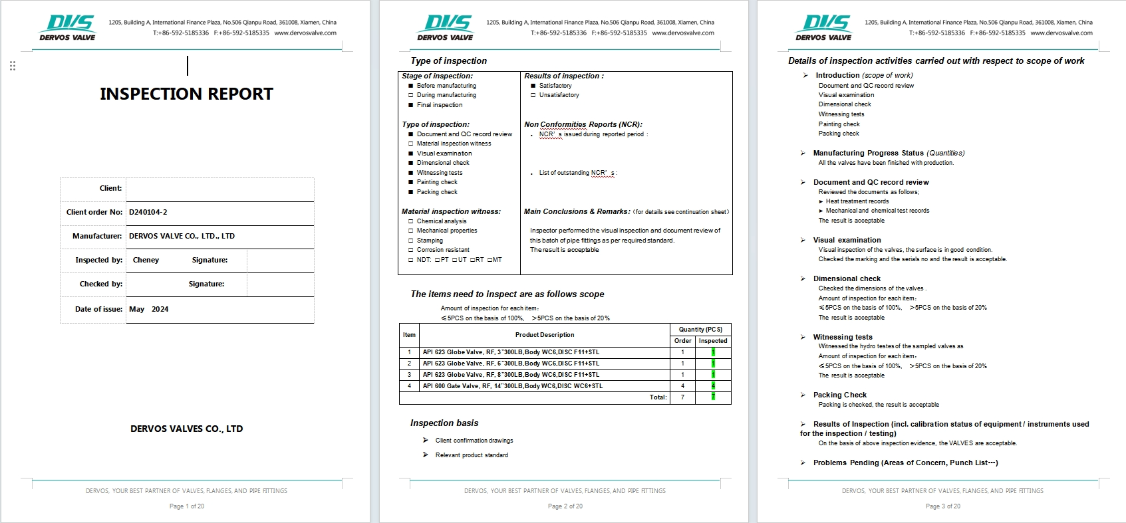

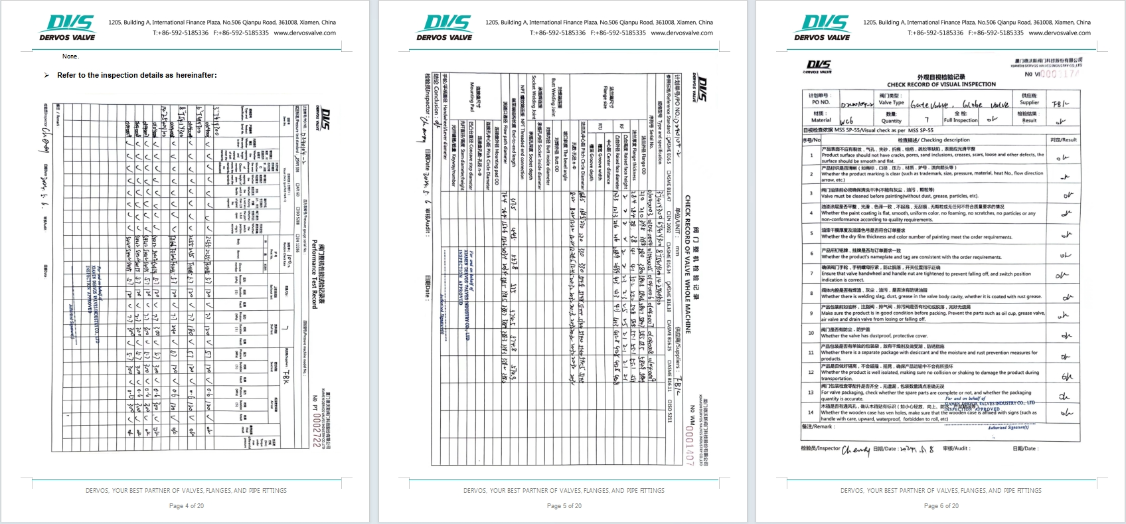

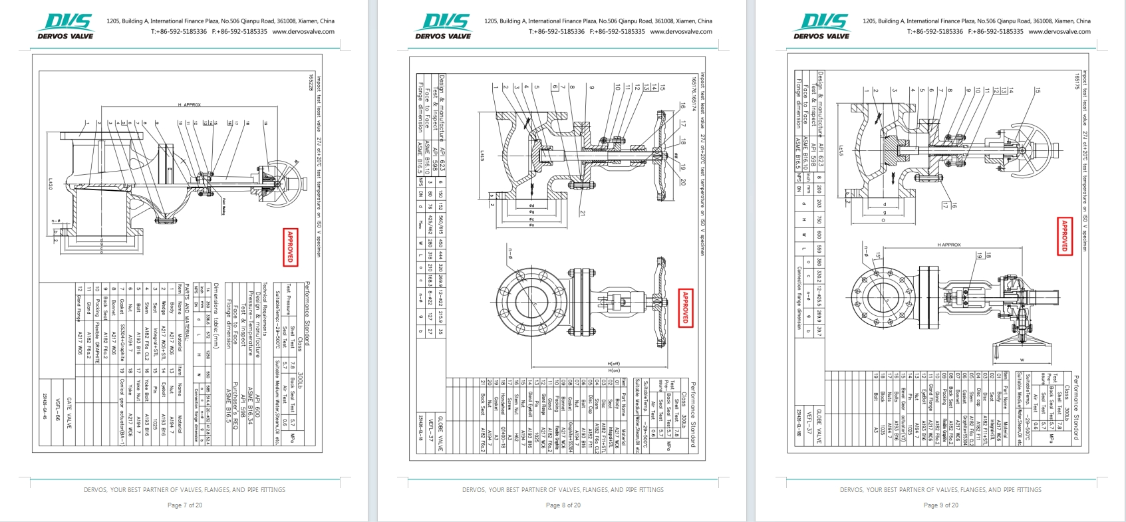

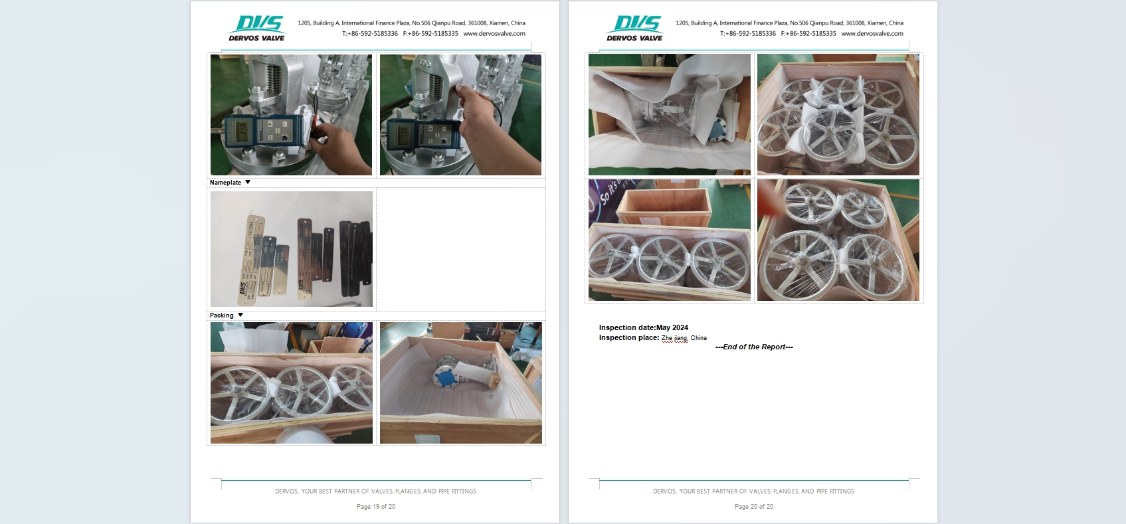

3" 300LB Alloy Steel Globe Valve is made according to API623 standard. The valve body is made of A217 WC6. It has the structural characteristics of through way type and structural length of 317.5mm. Its connection mode is RF. And it has hand wheel operation mode.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A216 WC6Method of Operation:

H.W.|

Type |

Alloy Steel Globe Valve |

|

Size |

3” |

|

Pressure |

300LB |

|

Connection |

RF |

|

Operation |

H.W. |

|

Body Material |

A216 WC6 |

|

Design Norm |

API 623 |

|

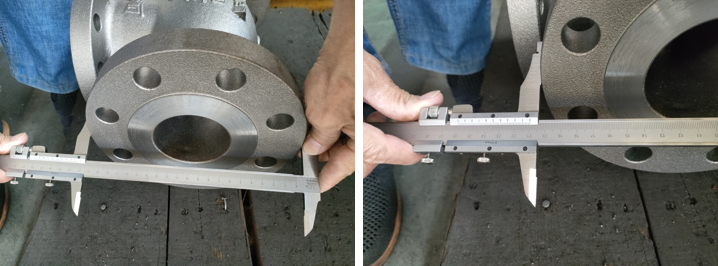

Face to Face |

ASME B16.10 |

|

Flange dimension |

ASME B16.5 |

|

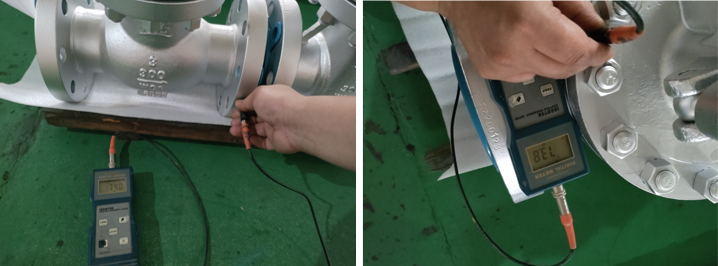

Test & Inspection Code |

API 598 |

|

Temperature |

-29 ~ 500°C |

|

Applicable Medium |

Water, Oil and Steam |

1. Alloy steel provides significantly higher strength and toughness compared to carbon steel, particularly after heat treatment processes such as quenching and tempering;

2. Alloy steel offers good resistance to high-temperature oxidation and thermal fatigue, making it suitable for applications involving temperature fluctuations and corrosive media.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.