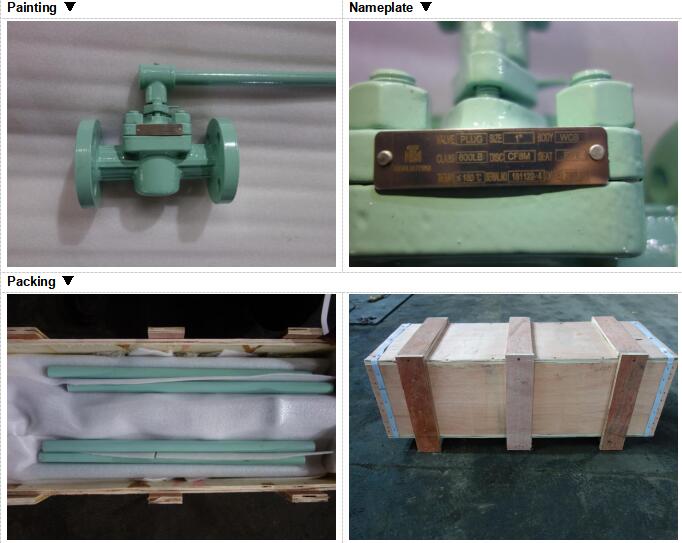

The 1 inch sleeved type plug valve is made of A216 WCB as per API 599. Thanks to its PTFE seat, the valve has excellent sealing and anti-corrosion performance. The valve is capable in working condition lower than 180 degree.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

WCBMethod of Operation:

Lever/Wrench

Quick Details

|

Type |

Plug Valve |

|

Size |

1 Inch |

|

DesignPressure |

Class 600 |

|

Construction |

Sleeve Type Plug Valve |

|

Connection Type |

Flange Connection |

|

Operation |

Lever/Wrench |

|

Design Code |

API599 |

|

Face to Face |

ASME B16.10 |

|

End Connection |

ASME B16.5 |

|

Pressure & Temp |

ASME B16.34 |

|

Test & Inspection |

API 598 |

|

Body Material |

A216 WCB |

|

Temperature Range |

<180℃ |

|

Application |

W.O.G |

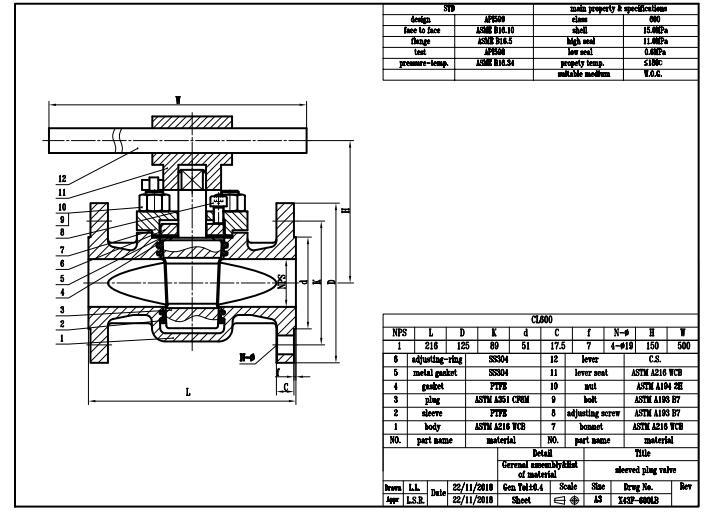

General description

The simplest form of a plug valve is the petcock. The body of a plug valve is machined to receive the tapered or cylindrical plug. The disk is a solid plug with a bored passage at a right angle to the longitudinal axis of the plug. In the open position, the passage in the plug lines up with the inlet and outlet ports of the valve.

When the cap is rotated 90 ° from the open position, the solid part of the cap blocks the ports and stops the flow of fluid. The plug valves are available in a lubricated or non-lubricated design and with a variety of styles of port openings through the plug, as well as a number of plug designs.

Technical Drawing

FAQ

1. Can the orders always be delivered on time?

Our purchasing team follows up very closely with each order to make sure on-time delivery for most of orders. In 2018, more than 90% orders were delivered on time, and we are dedicated to doing better.

2. What’s the normal delivery lead time?

For normal material, usually the delivery time is about 35~40 days, and for forged material, the delivery can even be shortened to 20~25 days. We believe the short lead time can make our offer more competitive and help you secure more orders.

3. Do you have different price levels for us?

With our numerous suppliers, different price levels are available with us, so we are able to help you win more customer from different markets requesting for high, medium and low prices.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.