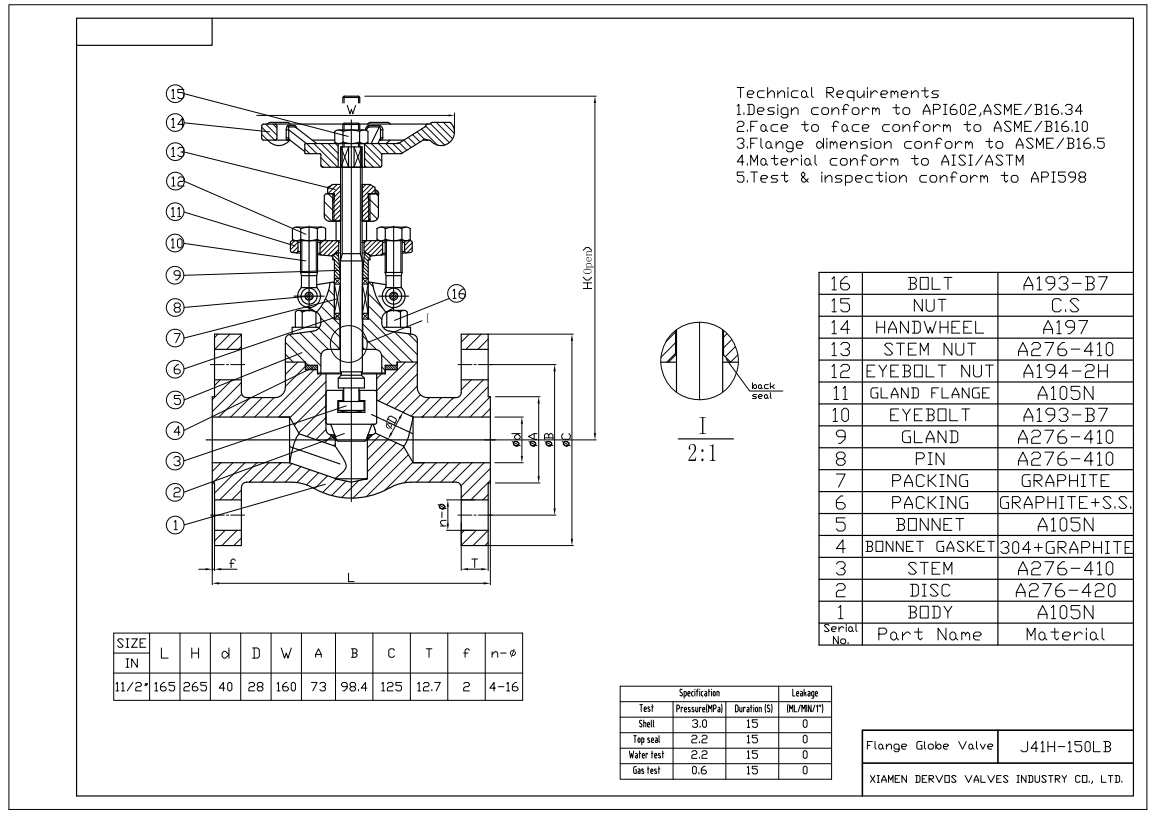

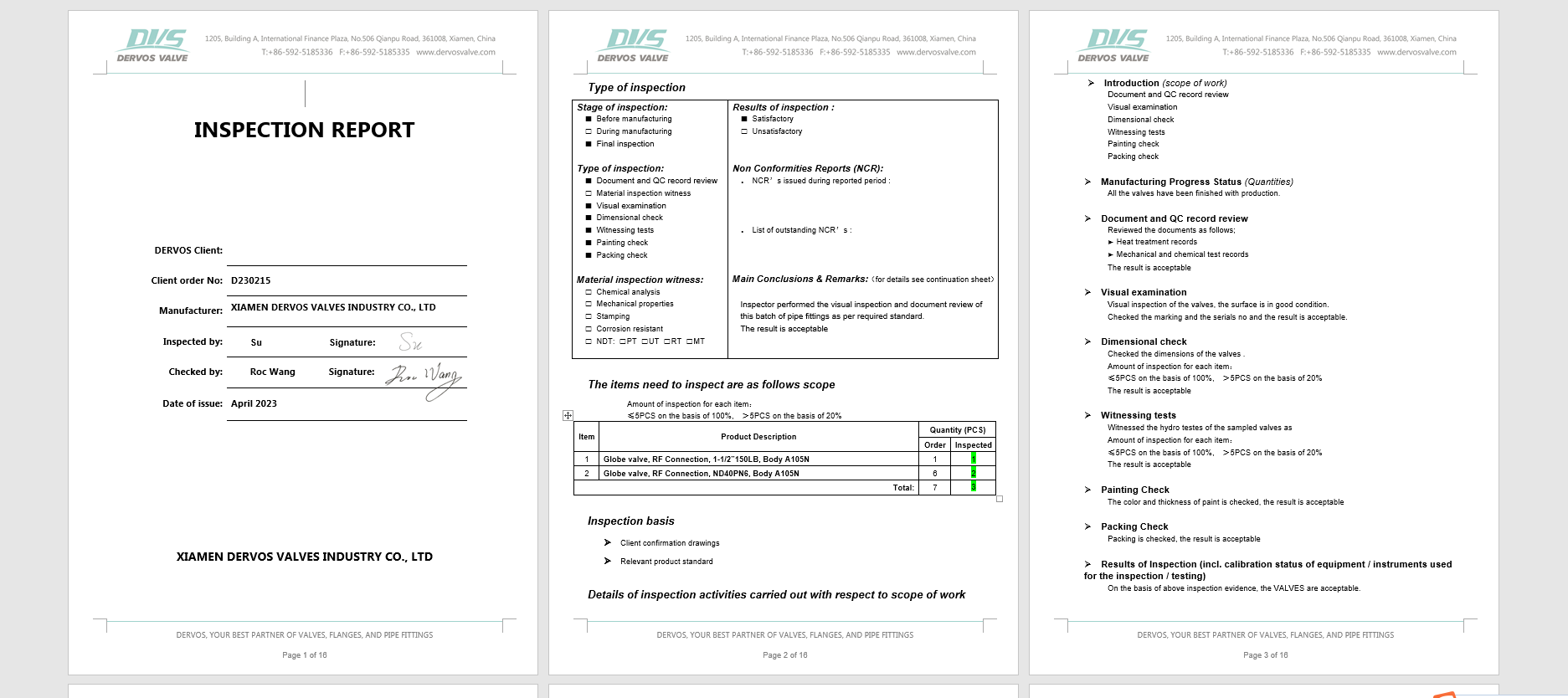

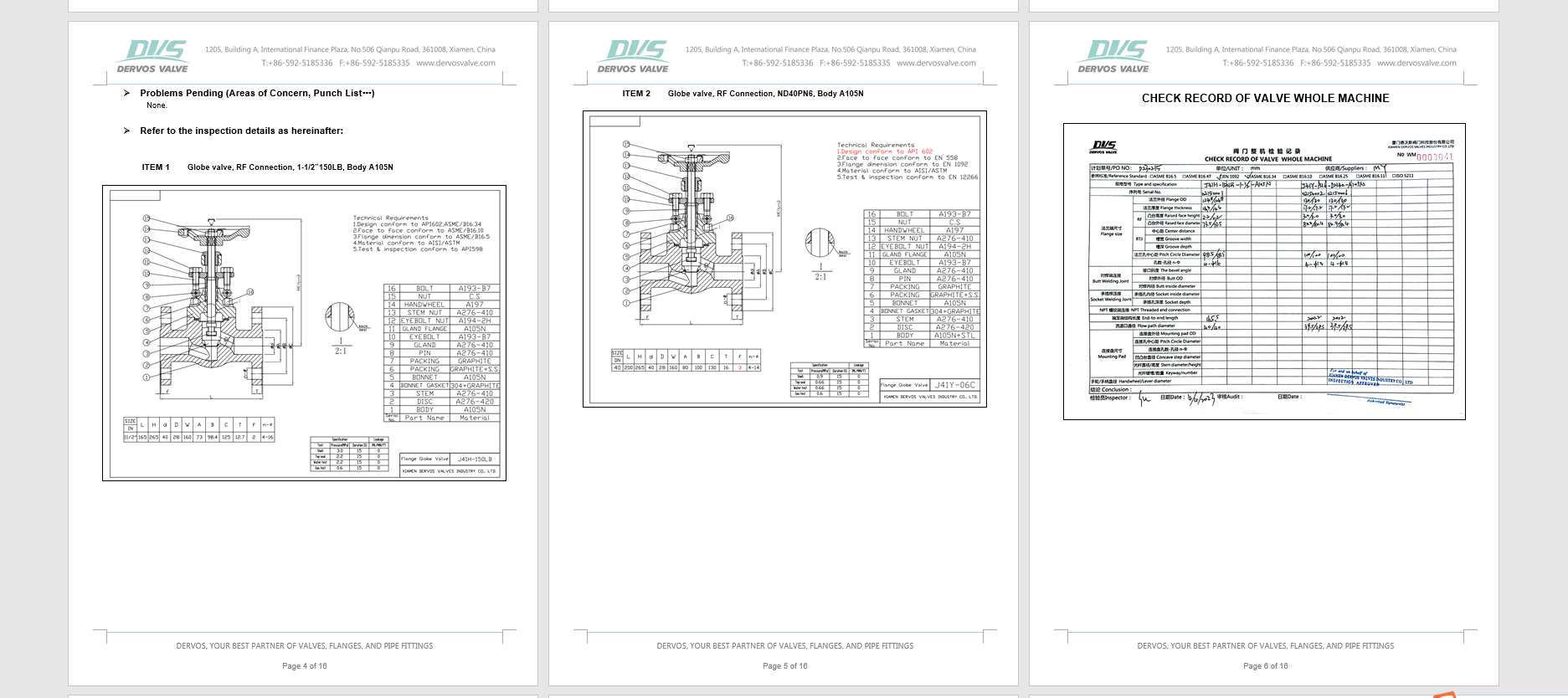

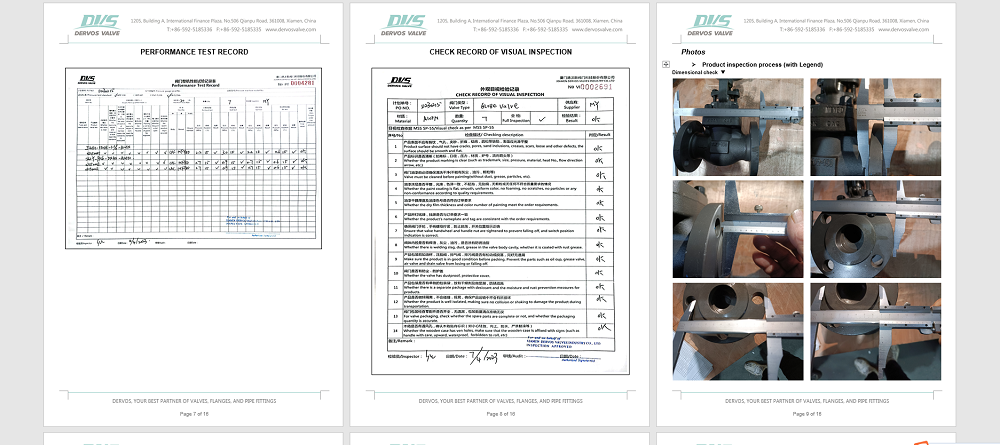

1 1/2'' 150LB forged steel globe valve is made according to API 602 standard. The valve body is made of A105N. It has the structural characteristics of BB, OS&Y. Its connection mode is RF. And it has hand wheel operation mode.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A105NMethod of Operation:

Hand Wheel

|

Type |

Forged Steel Globe Valve |

|

Size |

1 1/2'' |

|

Pressure |

150LB |

|

Connection |

RF |

|

Operation |

Hand Wheel |

|

Body Material |

A105N |

|

Design Norm |

API 602, ASME B16.34 |

|

Face to Face |

ASME B16.10 |

|

Flange Dimension |

ASME B16.5 |

|

Material |

AISI / ASTM |

|

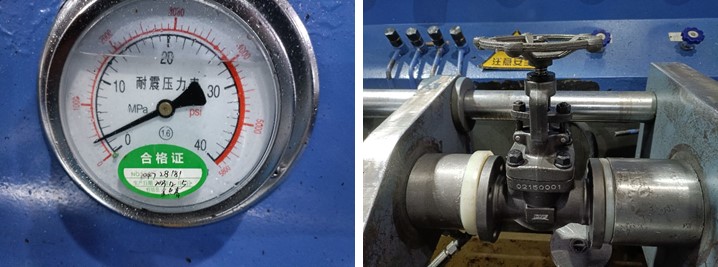

Test & Inspection Code |

API 598 |

|

Applicable Medium |

Water, Oil and Gas |

1. With a simple structure, forged steel globe valves are easy to dismantle and maintain, offering a long service life and cost-effectiveness;

2. Excellent sealing performance, effectively preventing medium leakage, especially suitable for systems that require strict sealing.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.