High Pressure Check Valve Supplier in China Offers Pressure-Seal Bonnet Check Valve, ASTM A105N, 1 Inch, Class 1500 LB, Forged Steel Lift Check Valve.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

ASTM A105NMethod of Operation:

Non

Quick Detail:

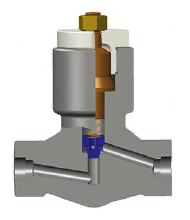

Type: Pressure-Seal Bonnet Check Valve.

Material: ASTM A105N.

Valve Size: 1 Inch.

Applicable Pressure Rating: Class 1500 LB.

Temperature Rating: Up to 500℃.

Molding Style: Forging.

Product Range:

Material: ASTM A105, ASTM A350 LF2, ASTM A182 F5, ASTM A182 F22, ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F347, ASTM A182 F321, ASTM A182 F51, ASTM A182 F55, Inconel Alloy, Monel Alloy, Hastelloy Alloy.

Standards: API 608, BS 5351, ASME B16.34/ B16.11/ B1.20.1/ B16.25.

Valve Size: 1/2 - 4 Inch.

Applicable Pressure Rating: Class 150 LB - 1500 LB.

Temperature Rating: Up to 500℃.

Molding Style: Forging.

FORGED STEEL LIFT CHECK VALVE - Pressure-Seal Cover

STANDARD MATERIALS

|

PART NAMES |

MATERIALS |

|

BODY |

ASTM A105, ASTM A350 LF2, ASTM A182 F5, ASTM A182 F22, ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F347, ASTM A182 F321, ASTM A182 F51, ASTM A182 F55, Inconel Alloy, Monel Alloy, Hastelloy Alloy. |

|

|

BONNET |

ASTM A105, ASTM A350 LF2, ASTM A182 F5, ASTM A182 F22, ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F347, ASTM A182 F321, ASTM A182 F51, ASTM A182 F55, Inconel Alloy, Monel Alloy, Hastelloy Alloy. |

|

|

SEAT |

ASTM A105 + HF |

|

|

DISC |

ASTM A276 420 |

|

|

P.S SEAT |

304 SS |

|

PRESSURE TEST ( A105 ) |

||||

|

CLASS |

SHELL (psig) |

BACKSEAT(psig) |

SEAT(psig) |

||

|

WATER |

WATER |

AIR |

WATER |

||

|

1500LB |

5575 |

- |

- |

4100 |

|

|

2500LB |

9275 |

6800 |

|||

Design and Manufacture Conform to: API 602, BS 5352, ASME B16.34/ B16.11/ B1.20.1/ B16.25.

Structure Features:

★ End Connection: Threaded, Socket-Welded or Butt-Welded

★ Pressure-Seal Cover

★ Reduced Bore / Full Bore

About Dervos

Xiamen Dervos Valves Industry Co.,Ltd (stock code 861601), founded in June 2008, is a one-stop industrial valves supplier integrated of R&D, manufacture, resource integration, and trade service. For 12 years, Dervos has been committed to finding solutions for industrial needs and providing professional service for both general and specialized valves.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.