Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai ChinaLead Time:

30~55 days Ex Works After Order ConfirmationMaterial:

Stainless Steel Butterfly ValveMethod of Operation:

Lever Butterfly Valve, Manual Butterfly ValveThe double offset high performance butterfly valve, with lever operation and lug body, is designed per API 609. The CF8M body and PTFE seat butterfly valve is more durable in serving the application.

Quick Detail

|

Type |

Butterfly Valve |

|

Size |

3'' |

|

Design Pressure |

150LB |

|

Construction |

Double Eccnetric, Soft Seat |

|

Connection Type |

Lug |

|

Operation |

Wrench Operated |

|

Design Code |

API 609 |

|

Face to Face |

ASMEB16.10 |

|

End Connection |

ASMEB16.5 |

|

Test & Inspection |

API 598 |

|

Body Material |

Stainless Steel CF8M |

|

Temperature Range |

-29℃~+150℃ |

|

Application |

Water, Oil, Gas |

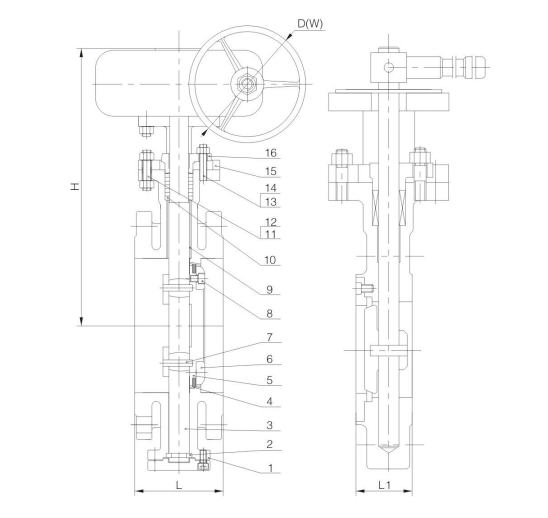

Dimension

| Class 150 | |||||||||||||

| DN | mm | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| NPS | in | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 |

| L | mm | 127 | 127 | 127 | 127 | 152 | 203.2 | 203.2 | 203.2 | 203.2 | |||

| in | 5 | 5 | 5 | 5 | 6 | 8 | 8 | 8 | 8 | ||||

| L1 | mm | 38.1 | 46 | 50.8 | 48 | 54 | 63.5 | 57 | 63.5 | 71.5 | 81 | 92 | 101.5 |

| in | 1.5 | 1.81 | 2 | 1.88 | 2.13 | 2.5 | 2.25 | 2.5 | 2.81 | 3.19 | 3.62 | 4 | |

| H | mm | 185 | 190 | 220 | 229 | 239 | 252 | 284 | 307 | 337 | 392 | 435 | 481 |

| in | 7328 | 7.48 | 8.7 | 9 | 9.4 | 9.9 | 11.2 | 12 | 13.3 | 15.4 | 17.1 | 19 | |

| D(W) | mm | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 200 | 200 | 250 | 250 | 300 |

| in | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 | 7.9 | 7.9 | 9.8 | 9.8 | 11.8 | |

| Weight (Kg) | mm | 12.5 | 13.5 | 17 | 38 | 72 | 105 | 148 | 182 | 230 | |||

| in | 8 | 9 | 10 | 10 | 11 | 14.5 | 34.2 | 66 | 98 | 134 | 168 | 200 | |

Related Knowledge

What is a high performance butterfly valve?

A high performance butterfly valve is often designed with double offset and PTFE seat, to handle everything from general applications to viscous and corrosive liquids; corrosive gases and steam.

Compared to concentric resilient seat butterfly valve, the disc of the high performance butterfly valve is arranged and positioned off the center of the pipe bore, which could reduce wear and tear to the valve during operation and increase sealing performance.

In conlusion, high performance butterfly valve is applicable for higher pressure and temperature applications. Meanwhile, it has longer cycle life and better sealing ability.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.