DN15 PN16 lift check valve is made according to BS 5352 standard. The valve body is made of A182-F304+STL. It has the structural characteristics of plug cover, lifting type with spring. Its connection mode is EN1092-1 B.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A182-F304+STLProduct Description

|

Type |

Lift Check Valve |

|

Size |

DN15 |

|

Pressure |

PN16 |

|

Connection |

EN1092-1 B |

|

Body Material |

A182-F304+STL |

|

Design Norm |

BS 5352 |

|

Face to Face |

EN 558 |

|

Flange Dimension |

EN 1092 |

|

Material |

AISI/ASTM |

|

Test & Inspection Code |

EN 12266 |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. When the medium flows in reverse, the valve disc can quickly close to prevent the medium from flowing back, ensuring the normal operation of the system and the safety of the equipment;

2. During design, the occurrence of water hammer can be reduced to avoid impact damage to the pipeline system.

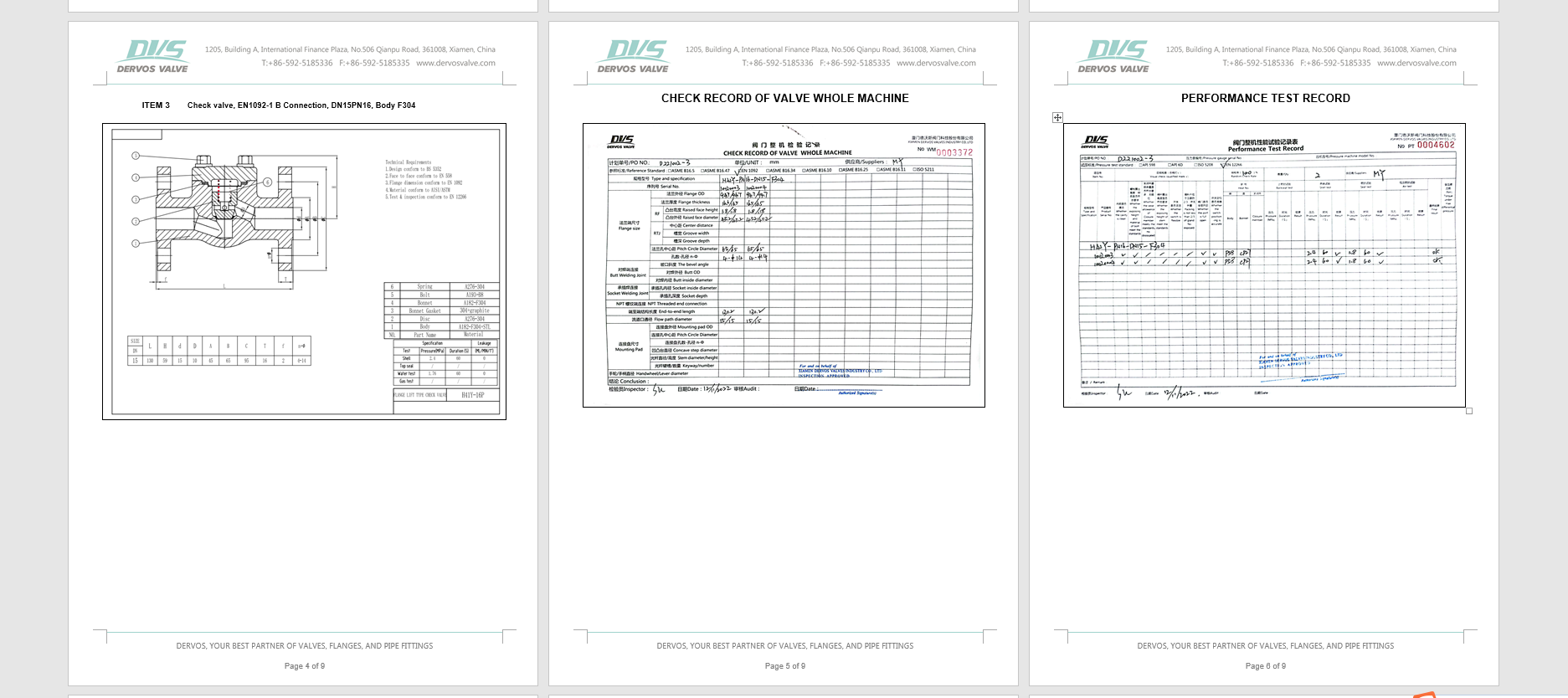

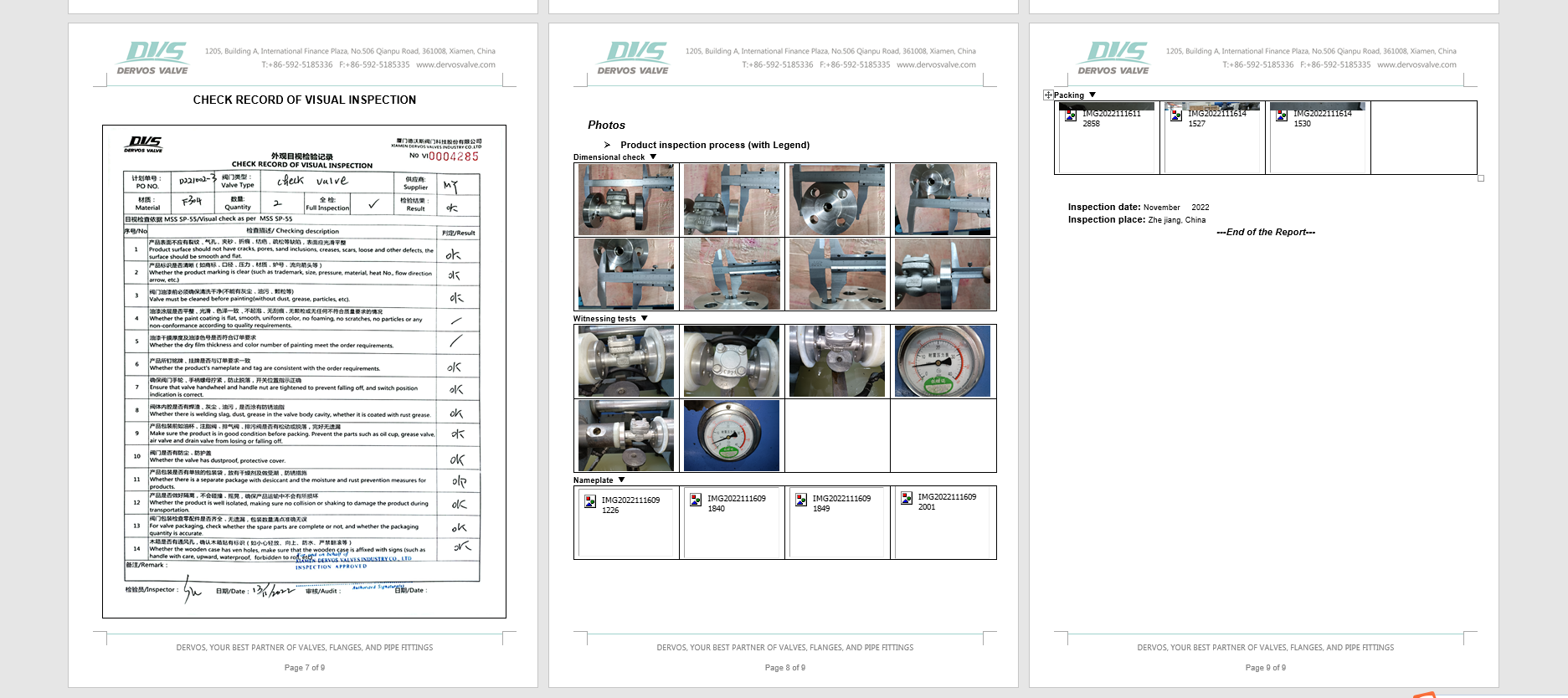

Technical Drawing

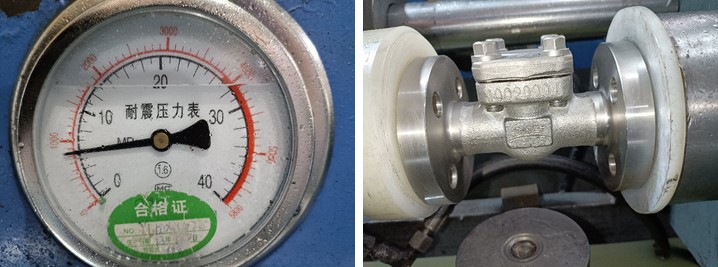

Dimension Checking

Pressure Testing

Nameplate & Packing

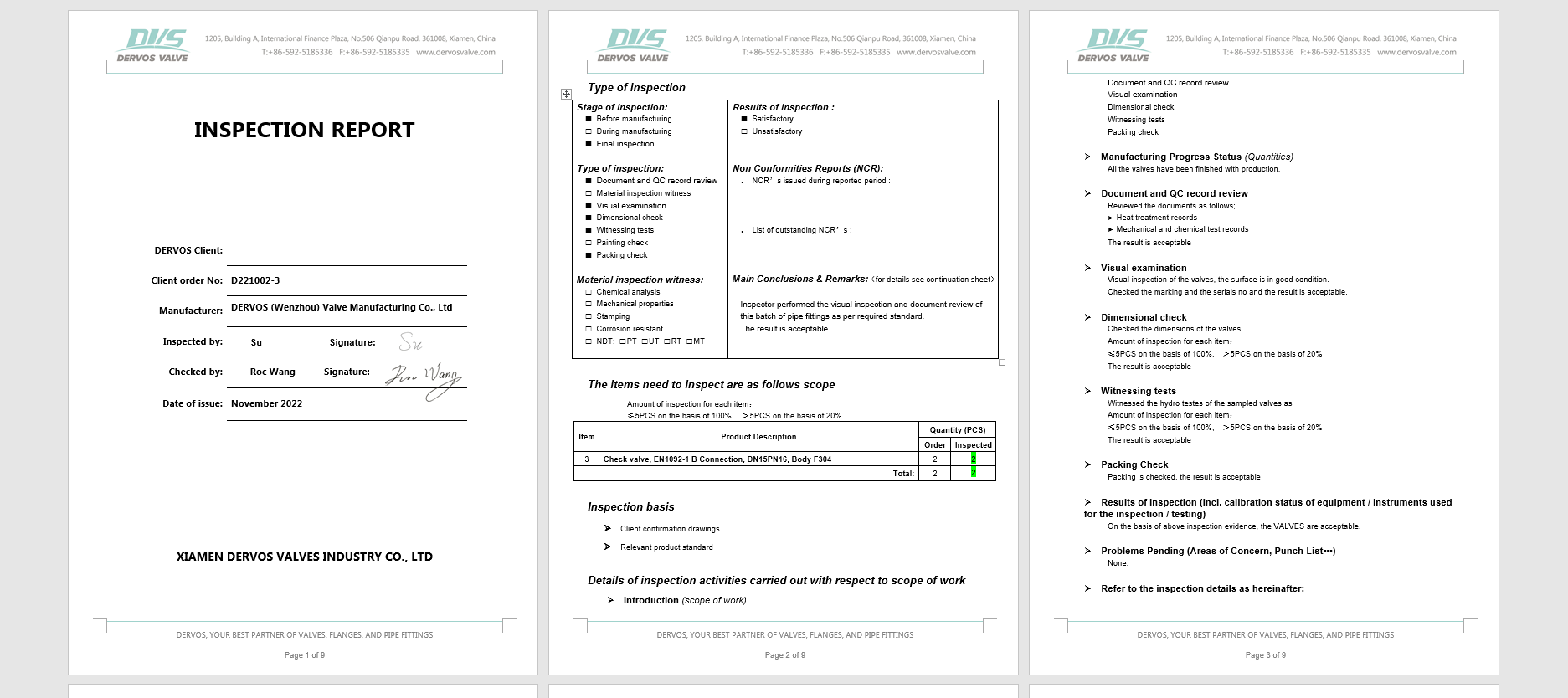

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.