NPS16 Class 150 check valve is made according to API6D standard. The valve body is made of ASTM A216 WCB+13Cr. Its connection mode is RF.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

ASTM A216 WCB+13CrProduct Description

|

Type |

Check Valve |

|

Size |

NPS16 |

|

Pressure |

Class 150 |

|

Connection |

RF |

|

Body Material |

ASTM A216 WCB+13Cr |

|

Design Norm |

API 6D |

|

Face to Face Dimension |

Customer requirements |

|

Flange Dimension |

ASME B16.5 |

|

Test & Inspection Code |

API 598 |

|

Temperature |

-29 ~ 120°C |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. Anti-Reverse Flow Function: The function of preventing fluid reflux is achieved through a heavy hammer device;

2. Compact Structure: Small footprint, suitable for installation environments with limited space;

3. Low Pressure Loss: Its design reduces pressure loss during fluid passage;

4. Excellent Sealing: A reliable sealing system ensures that the valve can effectively prevent fluid leakage when closed;

5. Multiple Material Options: Stainless steel, cast iron, copper alloy, and more.

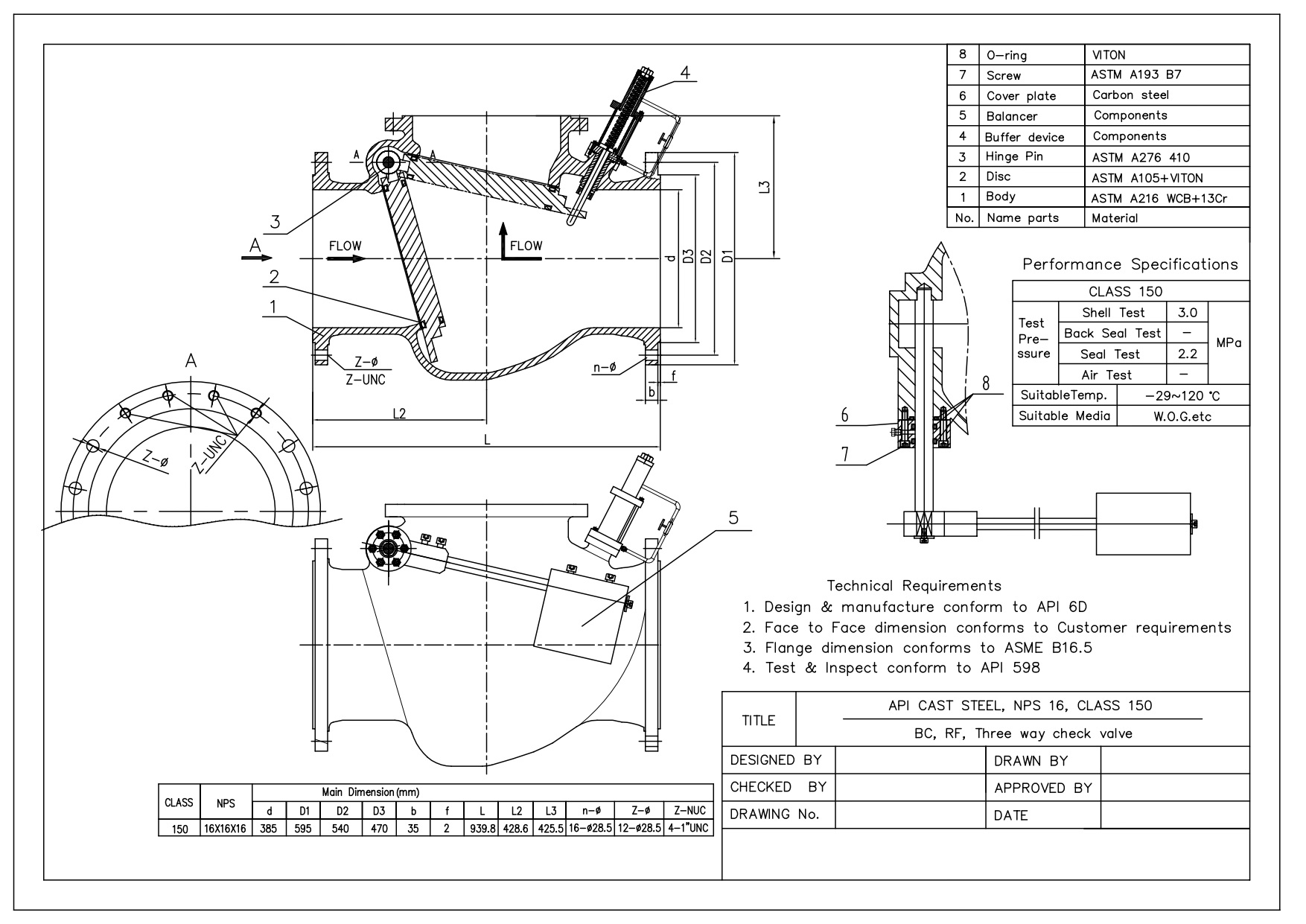

Technical Drawing

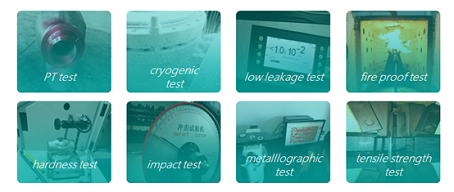

Witnessing tests

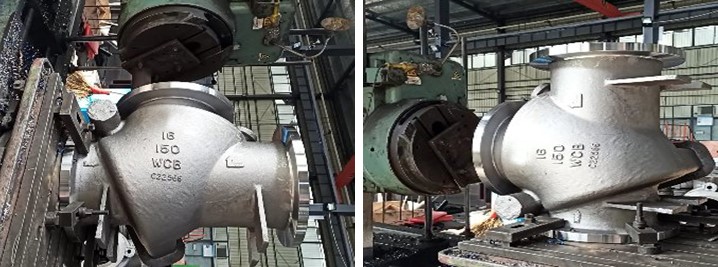

Finish products

Special Tests

Besides general tests we will do (hydraulic and air test), we could also do tensile strength test, metallographic test, fugitive emission test, and NDE test (UT,RT,PT,MT) upon customers’ specific requests.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.