The 3 inch 150LB expanding plug valves are designed for applications in which positive shutoff, verifiable zero leakage, and double block-and-bleed capabilities are required.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A216 WCBMethod of Operation:

HandwheelQuick Detail

|

Type |

Plug Valve |

|

Nominal Diameter |

3 Inch |

|

NominalPressure |

150 LB |

|

Construction |

DBB, Expanding Type, Non-Lubricated Type |

|

Connection |

RF |

|

Design & Manufacture |

API 6D |

|

F toF Dimension |

ASME B16.10 |

|

Test & Inspection |

API 6D |

|

Body Material |

A216 WCB |

|

Disc Material |

A216 WCB |

|

Side Valve Material |

Ductile Iron |

|

O-ring |

Teflon |

|

Temp. Range |

-29--150℃ |

|

Media |

Corrosive |

Features/Benefits

--Manufactured and tested to API 6D and ANSI B16.34 specifications

--Repairable on line

--Repeated positive shutoff

--Proved zero leakage

--Reduced wear on sealing surfaces

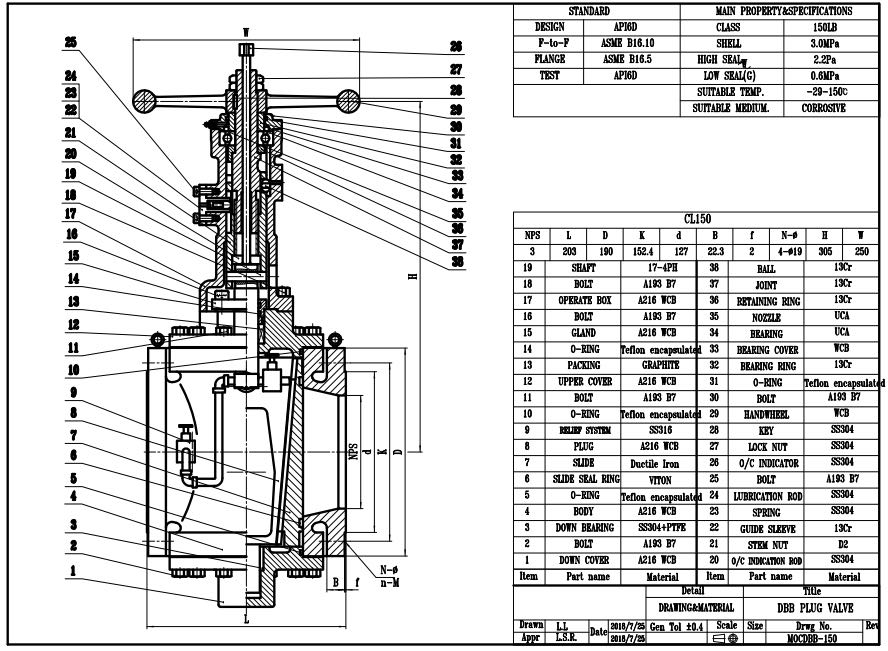

Technical Drawing

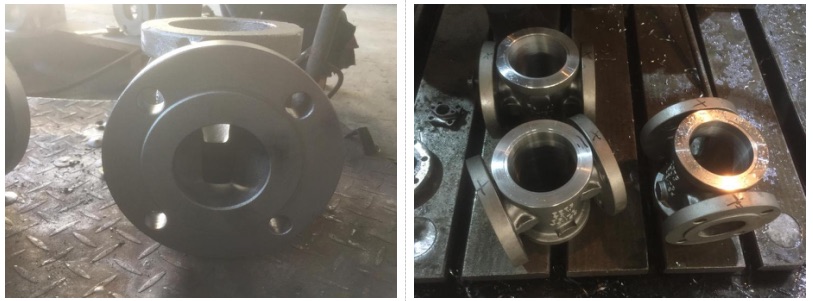

During Manufacturing

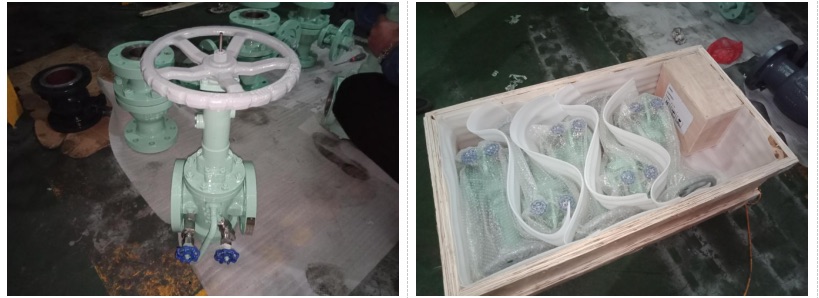

Packing

About Dervos

Xiamen Dervos Valves Industry Co.,Ltd (stock code 861601), founded in June 2008, is a one-stop industrial valves supplier integrated of R&D, manufacture, resource integration, and trade service. For 12 years, Dervos has been committed to finding solutions for industrial needs and providing professional service for both general and specialized valves.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.