Key International Standards for Butterfly Valves: Detailed Overview of API 609, ISO 5752, and JB/T 8527

2025-12-05

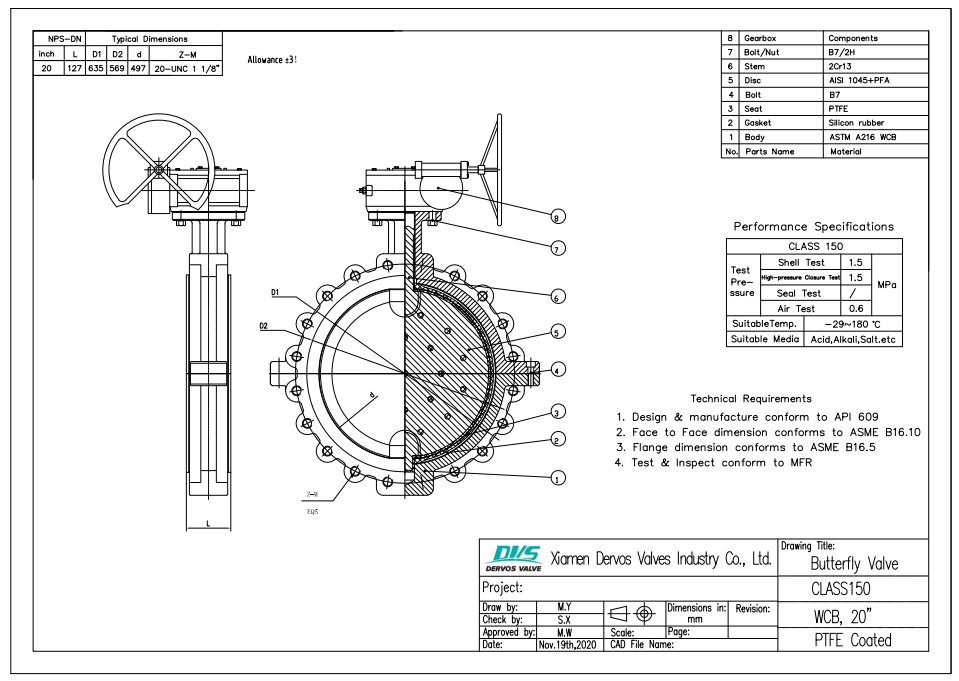

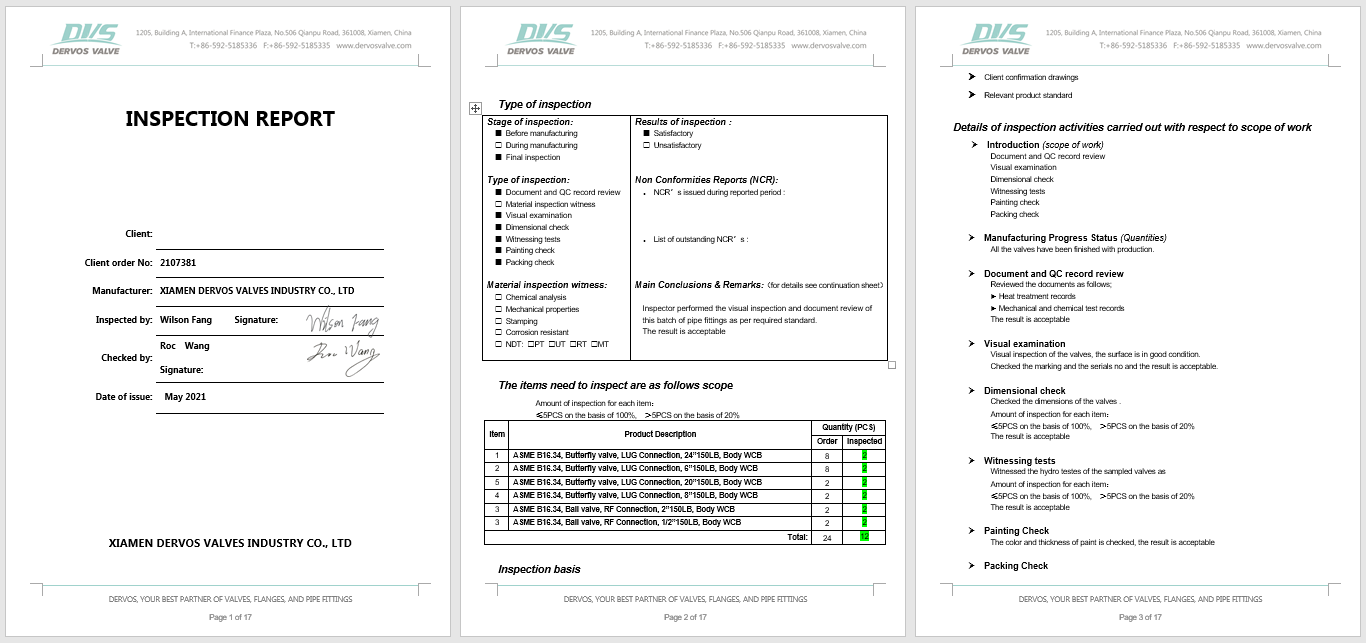

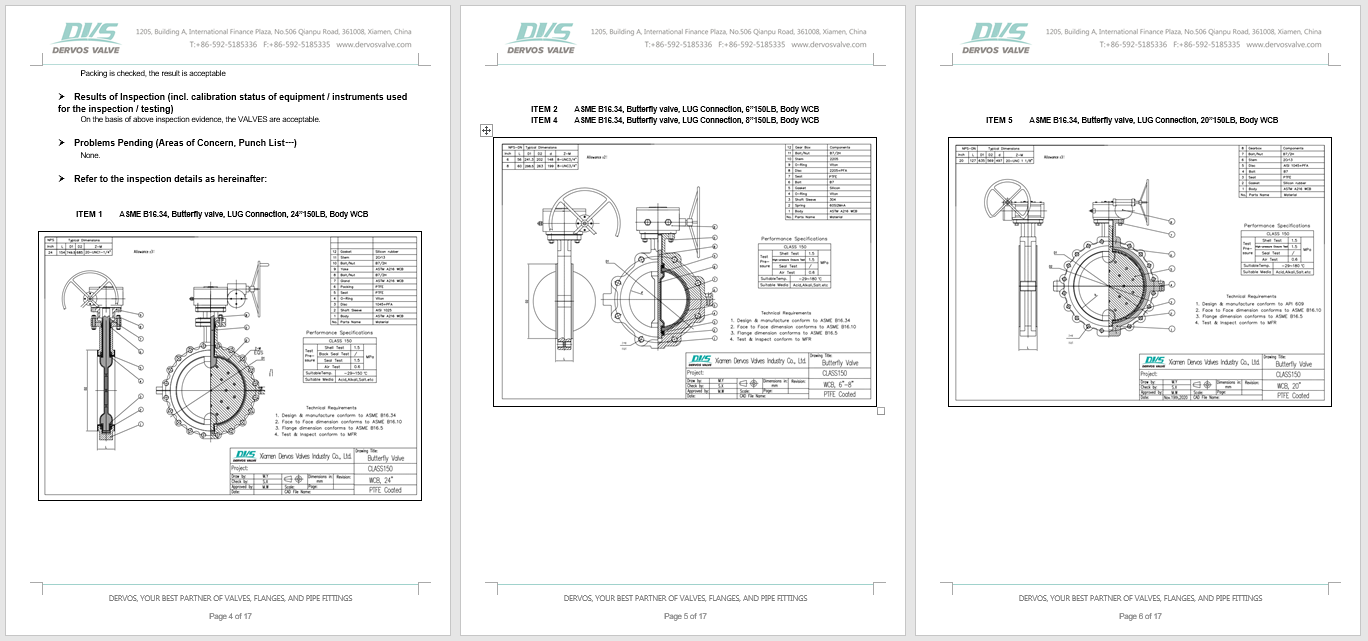

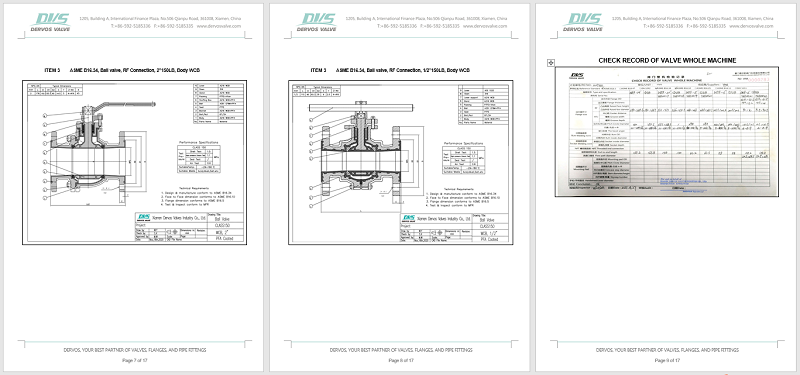

Butterfly valves are widely used in industrial piping systems due to their compact structure, lightweight design, and quick operation. They are commonly applied in water treatment, chemical, power, oil, and gas industries. However, when dealing with industrial standards across different countries and regions, selecting a butterfly valve that meets the relevant specifications is crucial. This article provides a detailed analysis of butterfly valve design and selection requirements based on three key standards: API 609, ISO 5752, and GB/T 12238. 1. API 609 — American Petroleum Institute Standard API 609 is the American Petroleum Institute (API) standard for metal-seated butterfly valves, primarily used in the oil, gas, and chemical industries. The standard defines valve structure, materials, dimensions, and pressure ratings to ensure reliable performance under high temperature, high pressure, and corrosive media conditions. Key points include: ● Pressure Ratings: Covers Class 150 to 1500, accommodating various service conditions. ● Body and Disc Design: Metal-to-metal sealing requires precise alignment between disc and seat to prevent leakage under high temperature or high pressure. ● Testing and Inspection: Includes shell tests, seat leakage tests, and operational performance checks to ensure valve safety and reliability. For high-temperature steam or high-pressure oil and gas pipelines, selecting a butterfly valve compliant with API 609 can significantly reduce leakage risk and extend equipment lifespan. 2. ISO 5752 — International Standard Organization Standard ISO 5752 is the International Organization for Standardization (ISO) standard that specifies end dimensions and flange connection sizes for valves. It defines the face-to-face dimensions, flange sizes, and connection methods for butterfly valves, providing a consistent interface specification for industrial users worldwide. Key points include: ● Face-to-Face Dimensions: Specifies valve lengths for different nominal diameters to ensure compatibility with piping systems. ● Flange Dimensions: Ensures valves match international standard pipe fittings, such as ANSI or DIN flanges. ● Interchangeability: Butterfly valves designed according to ISO 5752 can be replaced or serviced globally without redesigning the pipeline interface. ISO 5752 is particularly suitable for multinational engineering projects, ensuring the universality of butterfly valves across different plants and systems. 3. JB/T8527 — Chinese National Standard JB/T8527 is the Chinese national standard specifying the dimensions, structure, and testing requirements for metal hard-seal butterfly valves. It is widely applied in domestic industrial projects such as water conservancy, power, and petrochemical industries, serving as an important reference for procurement and acceptance. Key ...