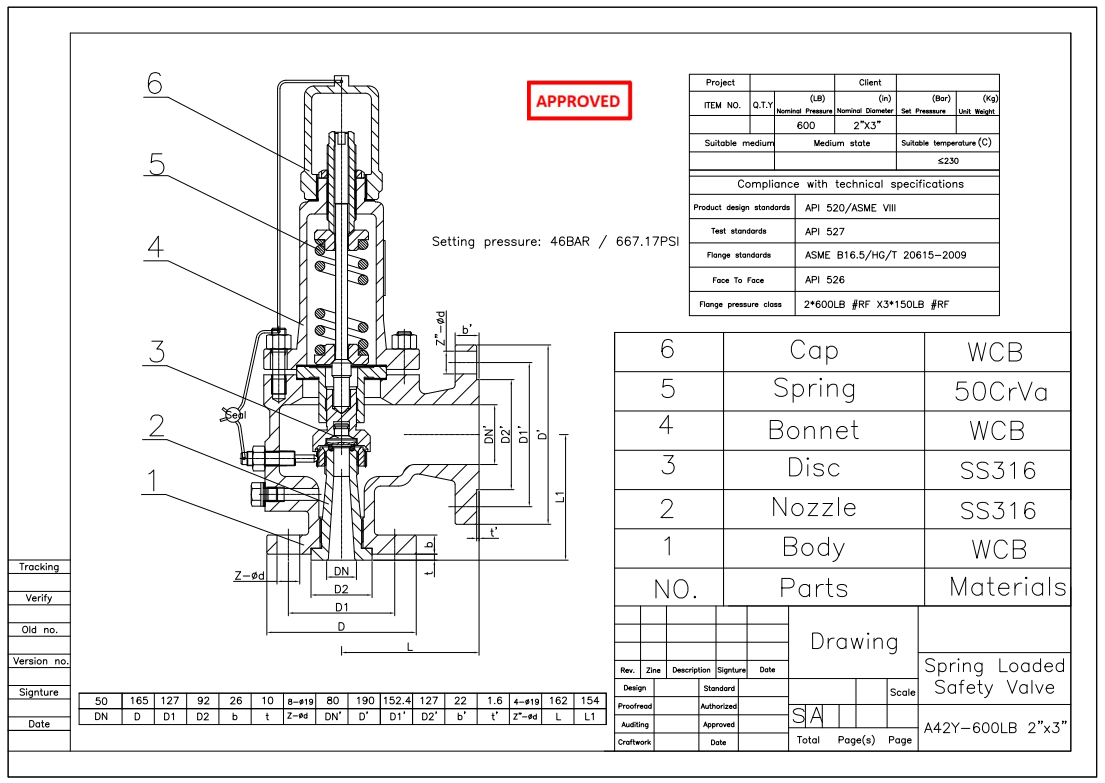

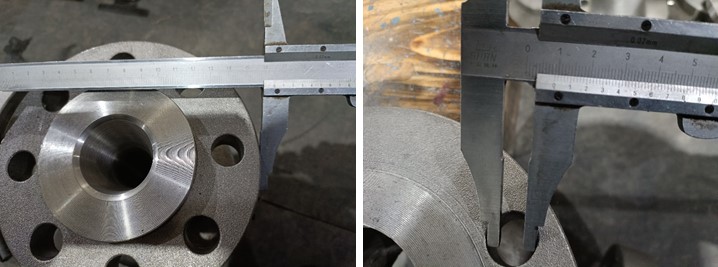

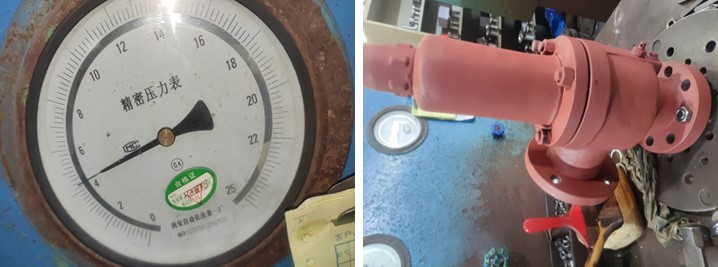

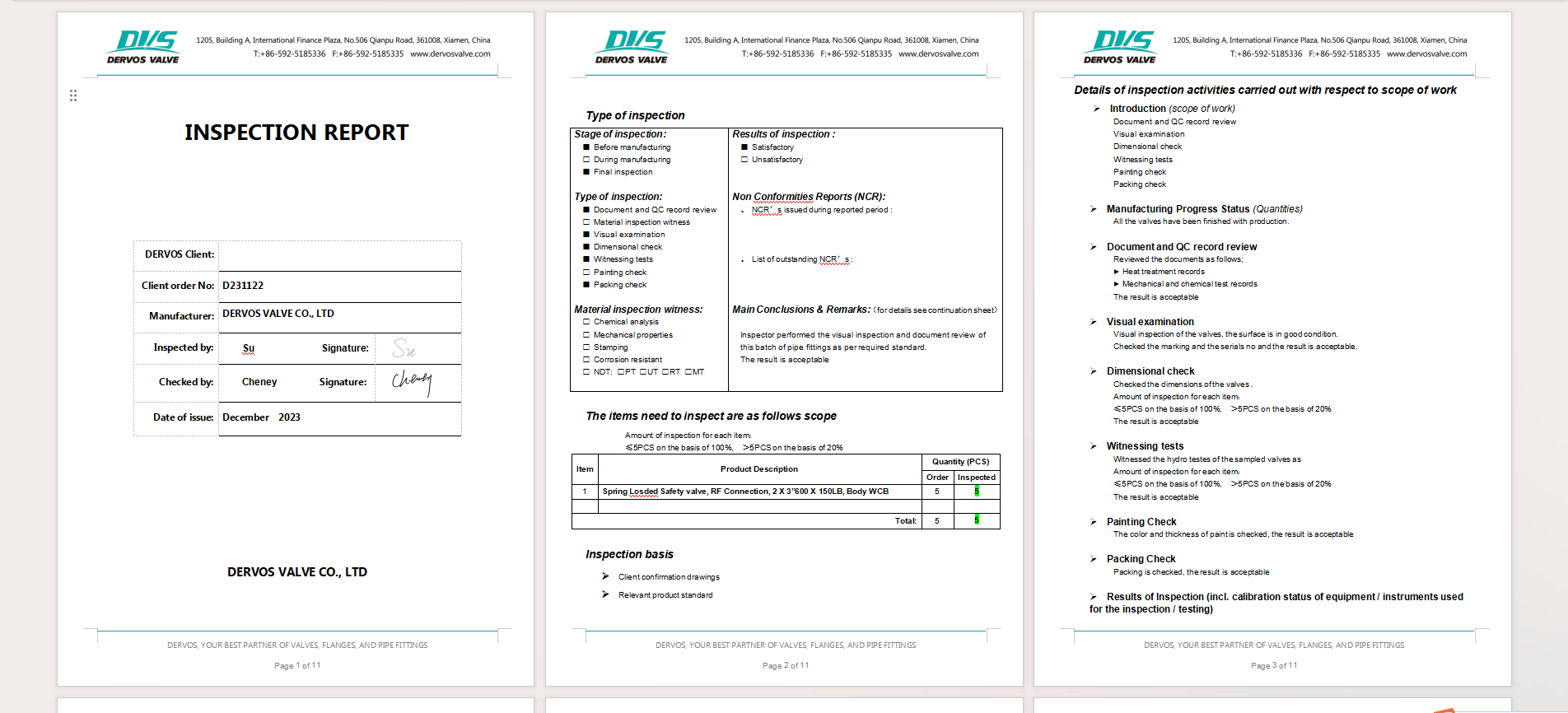

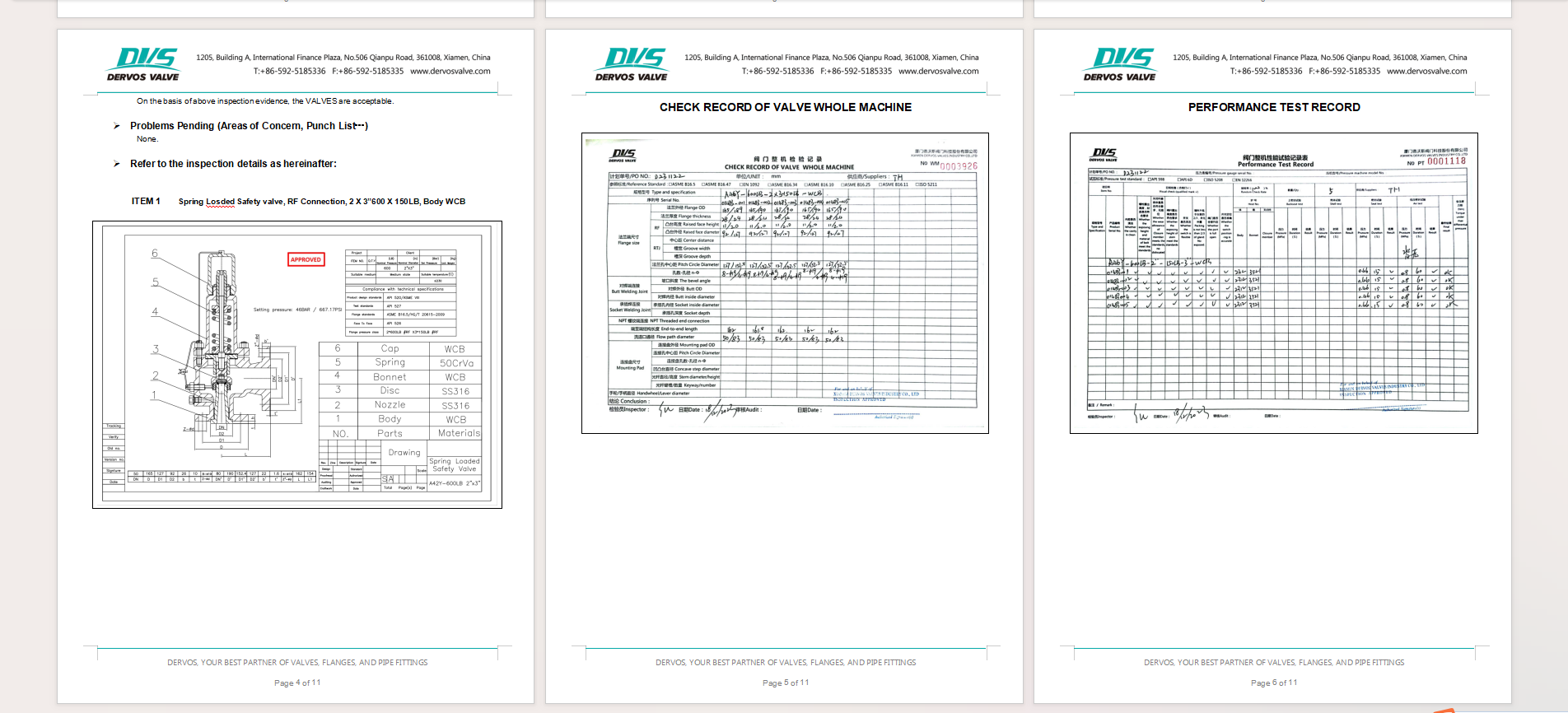

2" X 3" 600LB X 150LB spring loaded safety valve is made according to API 520 / ASME VIII standard. The valve body is made of WCB. It has the structural characteristics of fully open, spring loaded, suitable for media: hydrocarbons, channel diameter code H. Its connection mode is RF(ASME B16.5).

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

WCB

|

Type |

Spring Loaded Safety Valve |

|

Size |

2" X 3" |

|

Pressure |

600LB X 150LB |

|

Connection |

RF(ASME B16.5) |

|

Body Material |

WCB |

|

Design Norm |

API 520 / ASME VIII |

|

Flange Standards |

ASME B16.5/HG/T 20615-2009 |

|

Face to Face |

API 526 |

|

Test & Inspection Code |

API 527 |

|

Flange Pressure Class |

2*600LB #RF X 3*150LB #RF |

|

Temperature |

≤ 230°C |

|

Applicable Medium |

Water, Oil and Gas |

1. When the valve is opened, it can quickly discharge a large amount of medium, ensuring a rapid drop in pressure and protecting system safety;

2. Good sealing performance, effectively preventing medium leakage and ensuring safe operation.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.