The 3 inch 150LB butterfly valve has a double-offset disc design that allows the disc to move off the seat reducing running torque and seat wear. The Wafer type valve can be driven by a gearbox and handwheel or by electric, pneumatic or hydraulic actuator.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

CF8MMethod of Operation:

Lever

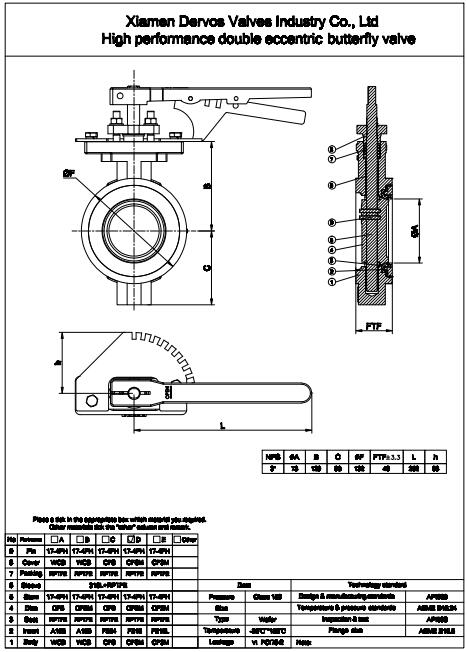

Specification table

|

Type |

Butterfly Valve |

|

Size |

3’’ |

|

Pressure |

150LB |

|

Structure |

Double Offset; Double Eccentric, Soft Seated |

|

Connection Type |

Wafer type |

|

Operation |

Lever operation |

|

Design Code |

API 609 |

|

Pressure Standards |

ASME B16.34 |

|

Test & Inspection |

API 598 |

|

Body Material |

CF8M |

|

Temperature Range |

-30℃~+180℃ |

|

Application |

Water, Oil, Gas |

Design features

1. Rational design, compact structure, easy to install and disassemble, maintenance-friendly

2. Dual eccentric structure reduces the friction onto the seal ring and prolong the service life.

3. Leakage free. Can be used in ultra-high vacuum conditions.

4. Different seals, plates, shafts and other materials are available for a wide range of media and temperature.

Technical Drawing

Report Available

Along with each order, Dervos will provide inspection reports and material test reports free of charge after shipment. All these certificates will let you have a clear picture of inspection process and results. Plus, these reports can be used for traceability.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.