Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai ChinaLead Time:

35~60 days Ex Works After Order ConfirmationMaterial:

Carbon Steel Globe Valve, Cast Steel Globe ValveMethod of Operation:

Gearbox Operation Globe ValveQuick Detail

|

Type |

Globe Valve |

|

Size |

6'' |

|

Design Pressure |

Class 1500 |

|

Construction |

Pressure Seal Bonnet, Plug Type Disc, Rising Stem |

|

Connection Type |

Butt Weld |

|

Operation Type |

Bevel Gearbox Opearted |

|

Design Code |

BS 1873 |

|

End to End |

ASME B16.10 |

|

Connection End |

ASME B16.25 |

|

Pressure & Temperature |

ASME B16.34 |

|

Test & Inspection Standard |

API 598 |

|

Body Material |

Cast Steel WCB |

|

Trim Material |

Trim NO. 5 |

|

Temperature Range |

-29℃~+425℃ |

|

Application |

WOG |

|

Origin |

China |

Material & Dimension

NPS

DN

Class

2

2 1/2

3

4

6

8

50

65

80

100

150

200

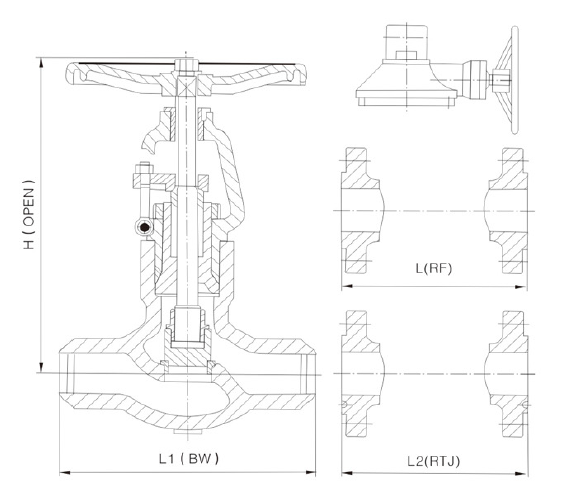

L(RF) L1(BW)

900LB

368

419

381

457

610

737

1500LB

368

419

470

546

705

832

2500LB

451

508

578

673

917

1022

L2(RTJ)

900LB

371

422

384

460

613

740

1500LB

371

422

473

549

711

841

2500LB

454

514

584

683

927

1038

H(Opne)

900LB

550

605

678

798

930

1230

1500LB

550

605

866

956

1260

1263

2500LB

560

720

755

1230

1791

2086

W

900LB

350

350

400

450

458

610*

1500LB

400

400

450

560

610*

610*

2500LB

400

450

560

310*

610*

760

Weight (RF)

900LB

78

108

102

142

400

960

1500LB

85

110

135

230

660

1590

2500LB

140

168

247

620

1500

3200

Weight (BW)

900LB

66

91

87

128

355

868

1500LB

77

101

122

209

595

1440

2500LB

100

118

180

438

1148

2594

*Manual gear

operator is recommended

No

Part Name

Carbon steel to

ASTM

Alloy

steel to ASTM

Stainless

steel to ASTM

WCB

WC6

WC9

C5

CF8

CF8M

CF3

CF3M

1

Body

A216 WCB

A217 WC6

A217 WC9

A217 C5

A351 CF8

A351 CF8M

A351 CF3

A351 CF3M

2

Seat Ring

A105

A182 F11

A182 F22

A182 F5

A182 F304

A182 F316

A182 F304L

A182 F316L

3

Disc

A105

A182 F11

A182 F22

A182 F5

A182 F304

A182 F316

A182 F304L

A182 F316L

4

Stem

A182 F6

A182 F304

A182 F304

A182 F316

A182 F304L

A182 F316L

5

Disc nut

A182 F6

A182 F304

A182 F304

A182 F316

A182 F304L

A182 F316L

6

Cap

SS Spiral Wound graphite or

SS Spiral Wound PTFE

7

Body Seal

Flexible Graphite+316

8

Adjustment Gasket

F6

F6

F316

9

Stem packing

Flexible Graphite+316

10

Gland Nut

A194 2H

A194 8

11

Gland Eyebolt

A193 B7

A193 B8

12

Pin

Carbon steel or Stainless

Steel

13

Cap Nut

Carbon steel or Stainless

Steel

14

Gland

A182 F6

A182 F304

A182 F316

A182 F304L

A182 F316L

15

Gland Flange

A216 WCB

A351 CF8

16

Yoke

A216 WCB

A351 CF8

17

Stem Nut

A439 D2 or B148-952A

18

Screw

Carbon steel

19

Handwheel

Ductile Iron or carbon

steel

20

Name Plate

Stainless steel or Aluminum

21

Washer

Carbon steel

22

Nut

Carbon steel or Stainless

Steel

Related Knowledge

Why do we use

pressure seal bonnet?

Pressure sealed

bonnet are often used for valves with high design pressure. The higher the

internal pressure gets, the greater the sealing force beween body and bonnet

become.

For bolted bonnet

valves, the body and bonnet are joined by studs and nuts with a gasket between

the flange faces to facilitate sealing. However,as system pressure

increases,the potential for leakage through the body and bonnet increases.

But for pressure sealed valve, “bonnet take-up bolts” to pull the bonnet up and seal against the pressure seal gasket. That is why when pressure increase, the performance of pressure seal gasket between body and bonnet becomes better.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.