Both V-port ball valves and O-port ball valves are important types of ball valves, with clear differences in design, applicable media, and control performance. Understanding these differences helps engineers make more appropriate selections for specific applications.

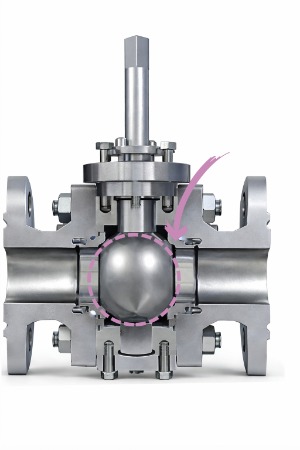

V-port ball valves feature a distinctive partial-sphere ball design with a V-shaped port on one side. By adjusting the opening position of the ball, the valve enables precise control of the process flow and provides excellent throttling performance.

In addition, this valve design offers a self-cleaning effect and is suitable for services involving fibrous media, fine particles, or slurries. It provides a wide turndown ratio and supports accurate control at low flow rates.

In the figure above, the valve trim is a quarter-sphere ball, which is a type of V-port ball valve trim.

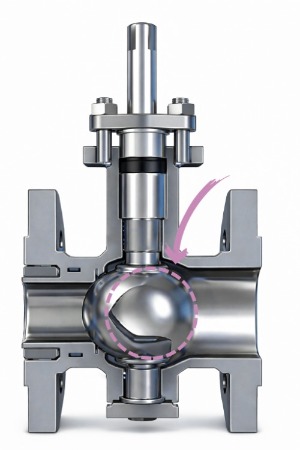

O-port ball valves use a full-sphere ball with a complete circular flow passage, resulting in low flow resistance and fast on/off operation, requiring only a 90° rotation. They are commonly used in applications where rapid shut-off is required.

These valves provide good sealing performance and are suitable for gas, steam, liquids, and media containing small amounts of suspended solids.