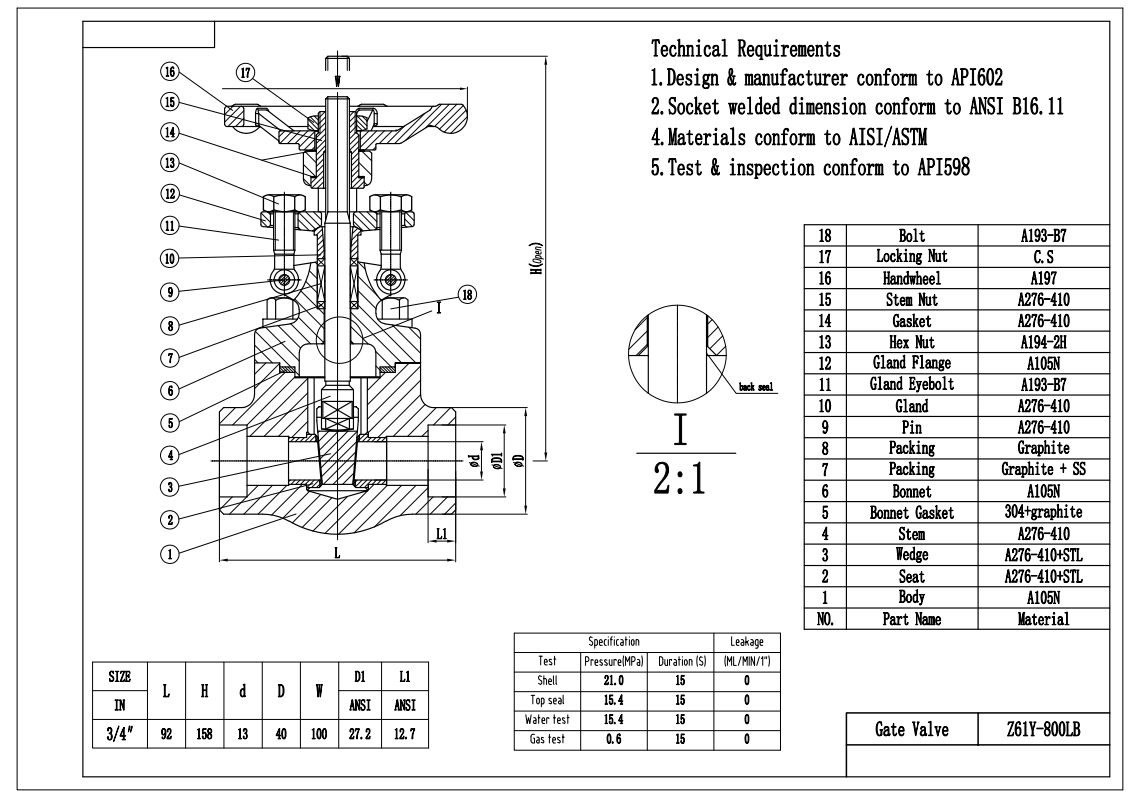

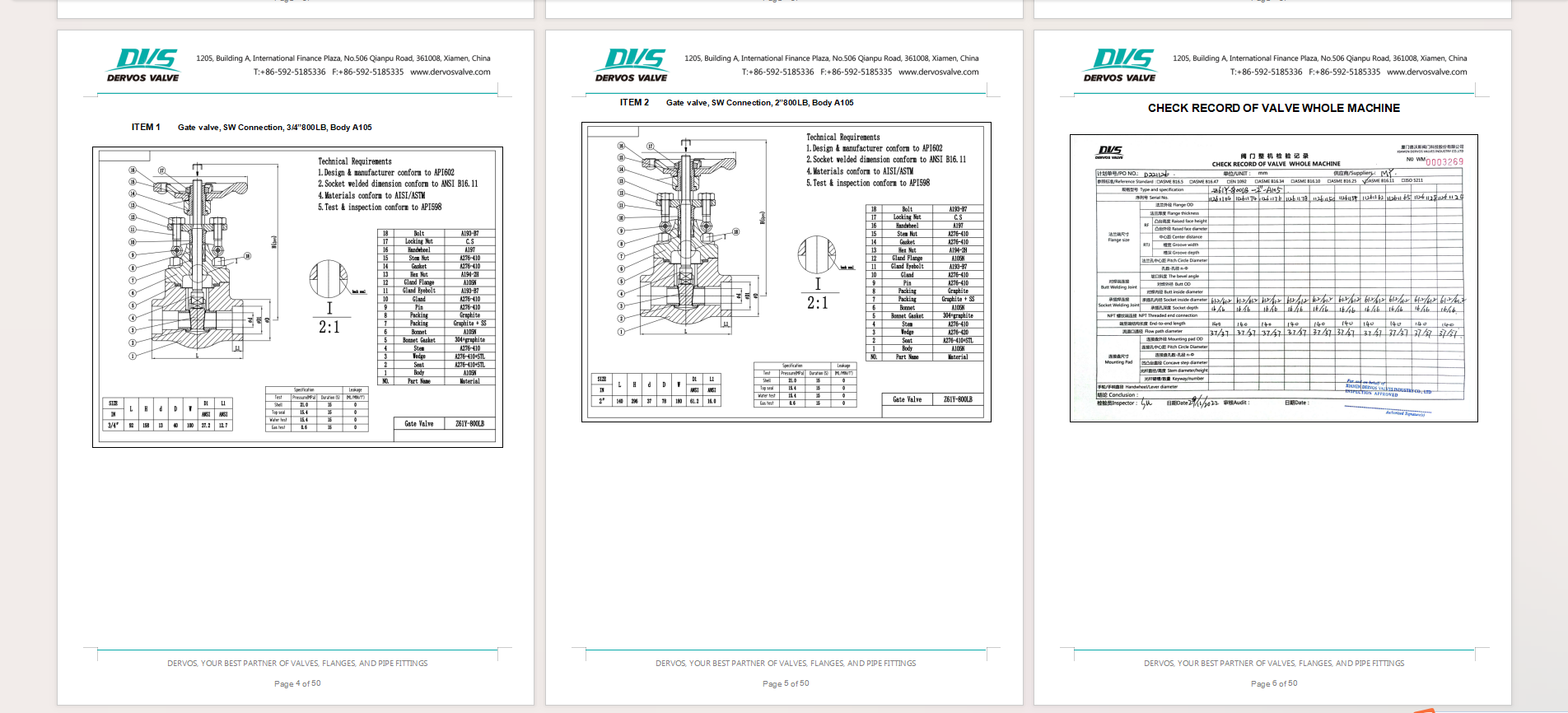

3/4" 800LB forged steel gate valve is made according to API 602 standard. The valve body is made of A105N. It has the structural characteristics of bolt cover, rising stem, OS&Y, reduced diameter. Its connection mode is SW. And it has hand wheel operation mode.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A105NMethod of Operation:

Hand WheelProduct Description

|

Type |

Forged Steel Gate Valve |

|

Size |

3/4" |

|

Pressure |

800LB |

|

Connection |

SW |

|

Operation |

Hand Wheel |

|

Body Material |

A105N |

|

Design Norm |

API 602 |

|

Socket Welded Dimension |

ANSI B16.11 |

|

Materials |

AISI/ASTM |

|

Test & Inspection Code |

API 598 |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. The sealing surface of forged steel gate valves is usually made of wear-resistant and corrosion-resistant alloy materials, which can maintain reliable sealing performance for a long time;

2. Forged steel gate valves are manufactured using forging technology. After high-temperature forging, the grain structure of the material becomes denser, with higher strength and durability than cast steel gate valves, making it particularly suitable for harsh working conditions such as high pressure and high temperature.

Technical Drawing

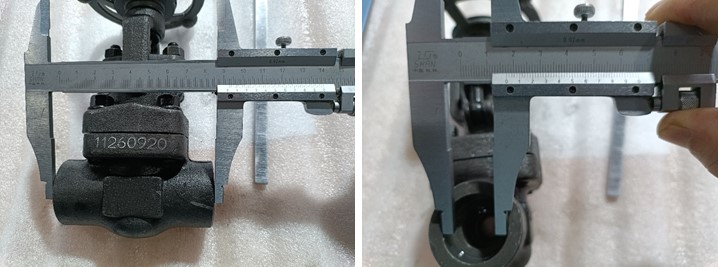

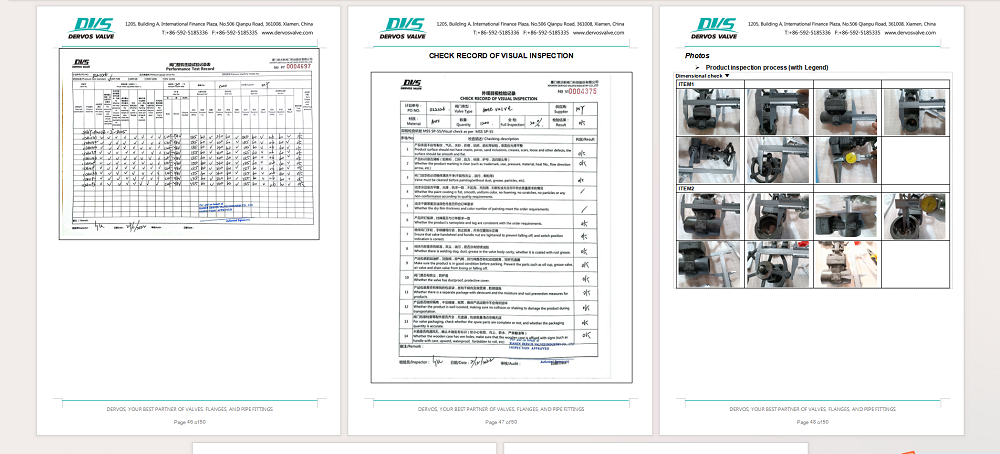

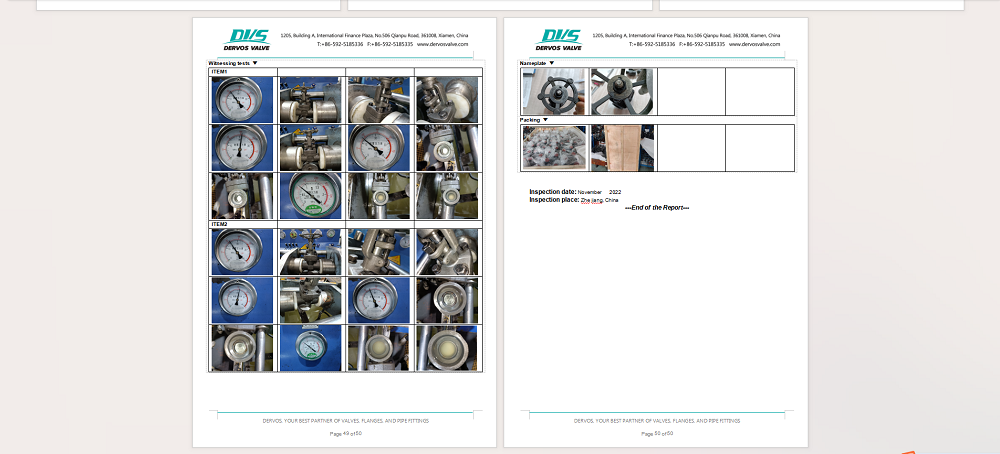

Dimension Checking

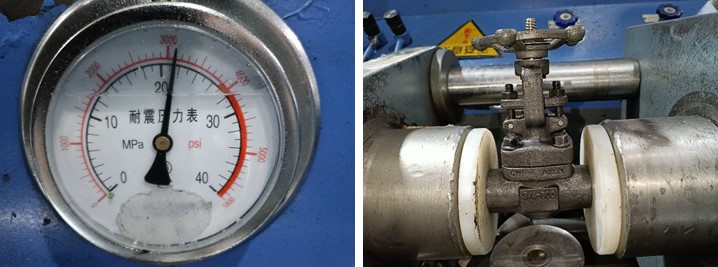

Pressure Testing

Nameplate & Packing

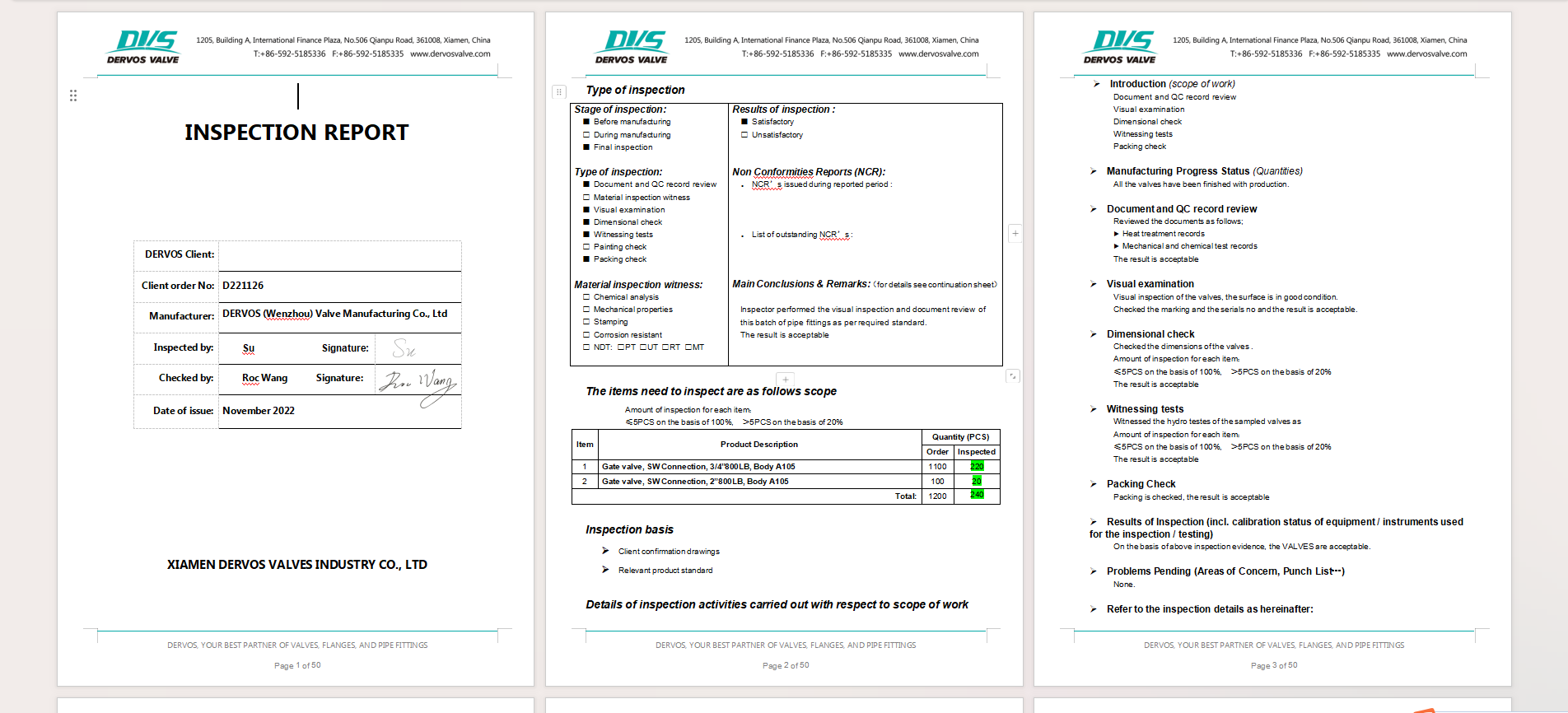

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.