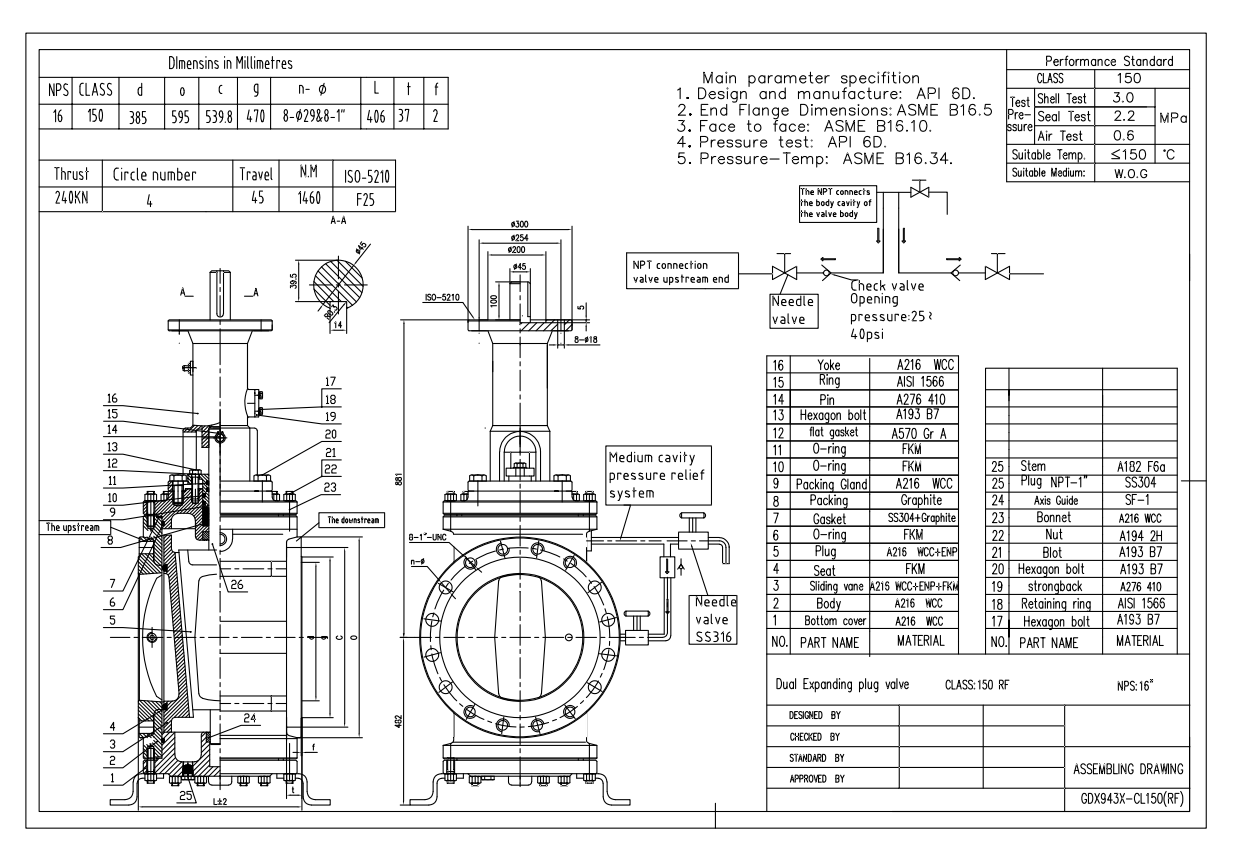

16" 150LB plug valve is made according to API6D standard. The valve body is made of A216 WCC. It has the structural characteristics of DBB, suitable for mediums such as Naptha, Gasoline, MTBE. Its connection mode is RF.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A216 WCCProduct Description

|

Type |

Double Sealed Track Plug Valve |

|

Size |

16" |

|

Pressure |

150LB |

|

Connection |

RF |

|

Body Material |

A216 WCC |

|

Design Norm |

API 6D |

|

Face to Face |

ASME B16.10 |

|

End Flange Dimensions |

ASME B16.5 |

|

Pressure Test |

API 6D |

|

Pressure-Temp |

ASME B16.34 |

|

Temperature |

≤ 150°C |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. The plug valve utilizes a dual sealing system that ensures a tight seal, significantly reducing the risk of leakage in critical applications.

2. The plug valve design of the Double Sealed Track Plug Valve allows for quick and easy operation, with low fluid resistance, making it an ideal choice for applications requiring frequent valve adjustments.

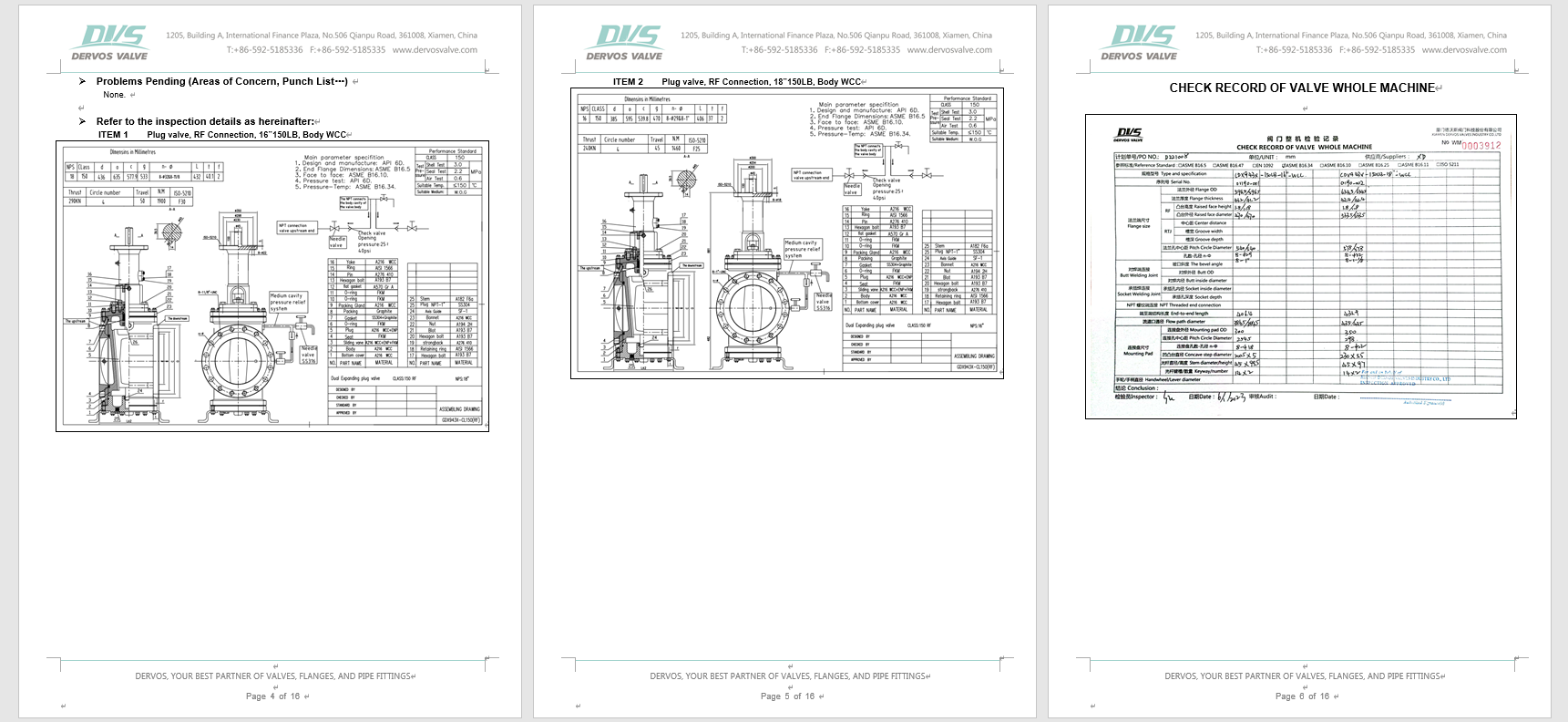

Technical Drawing

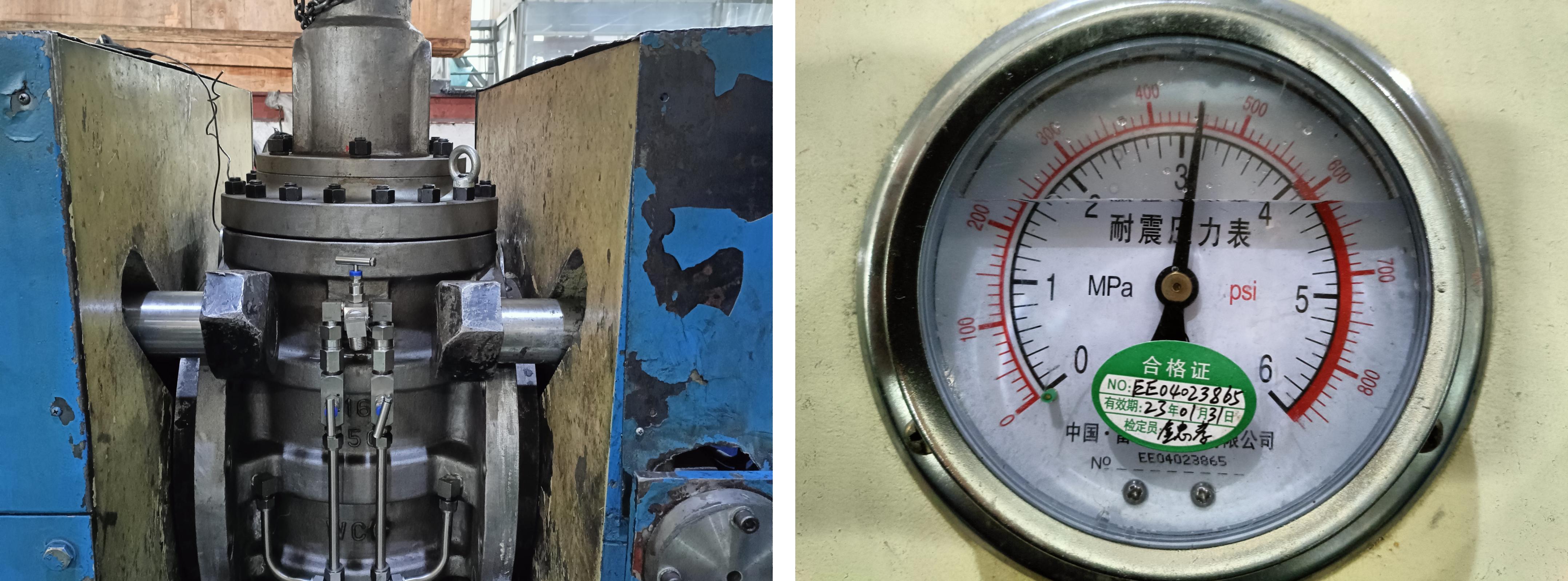

Dimension Checking

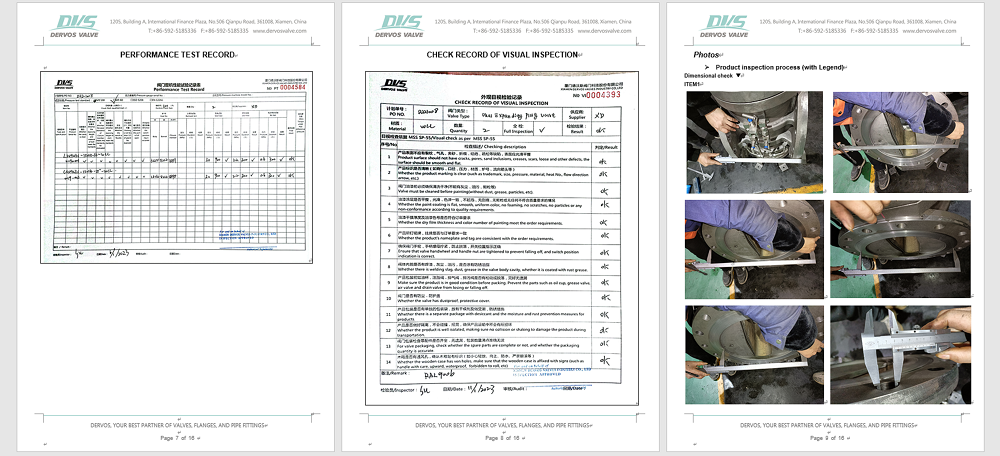

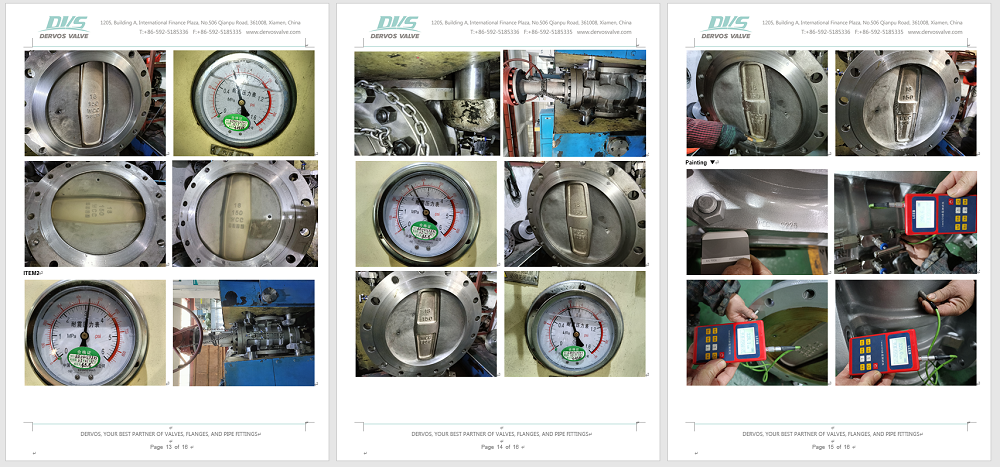

Pressure Testing

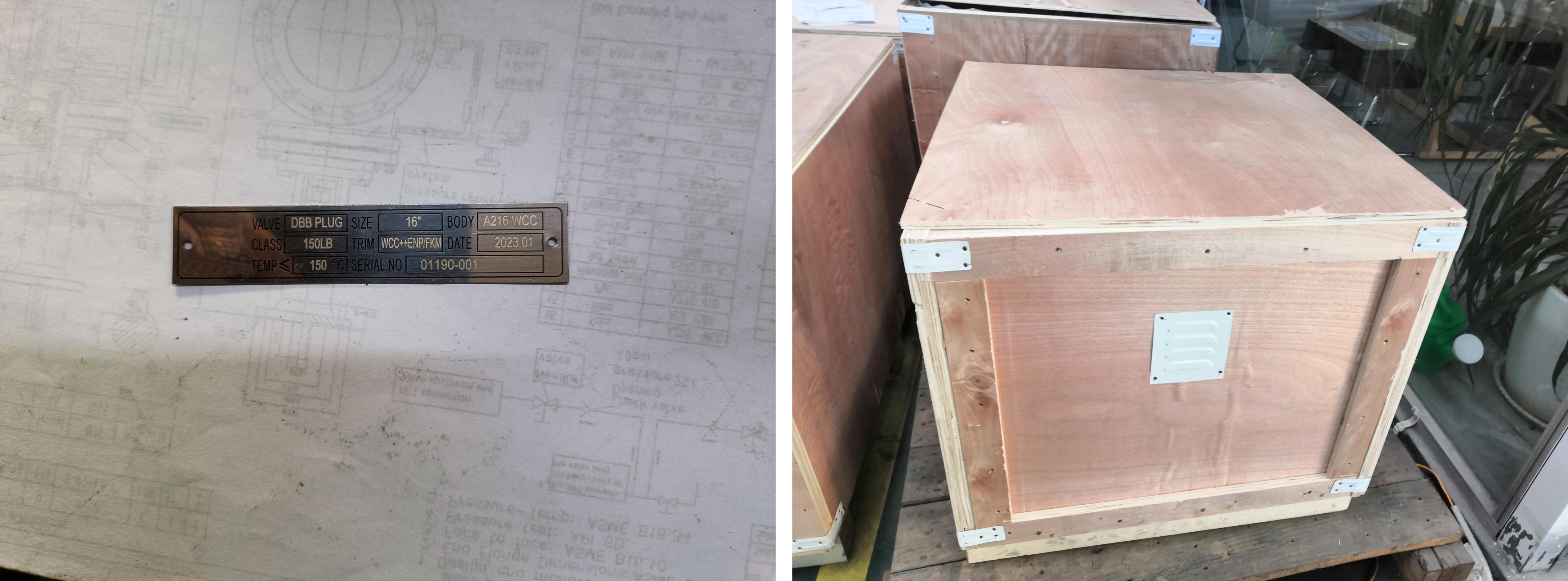

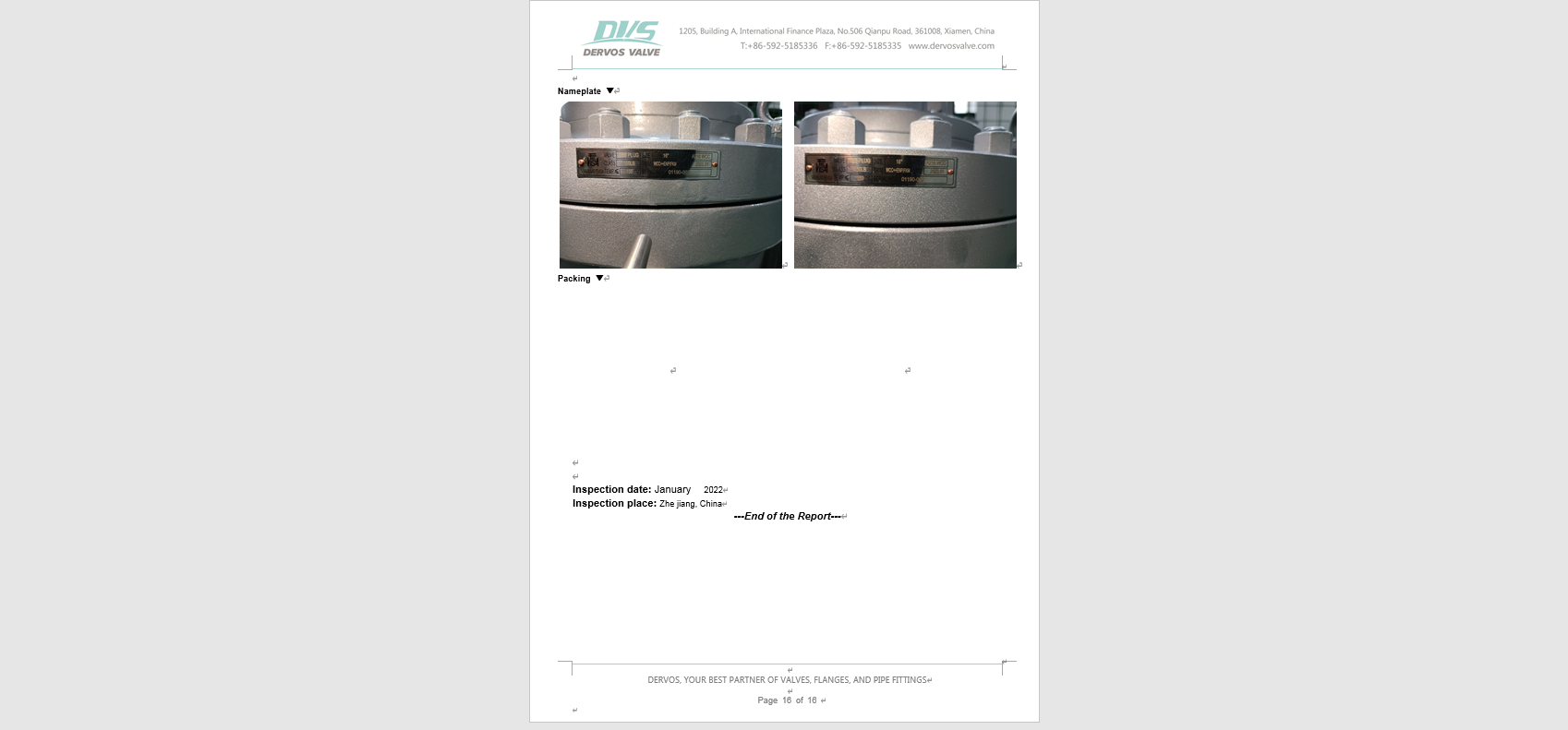

Nameplate & Packing

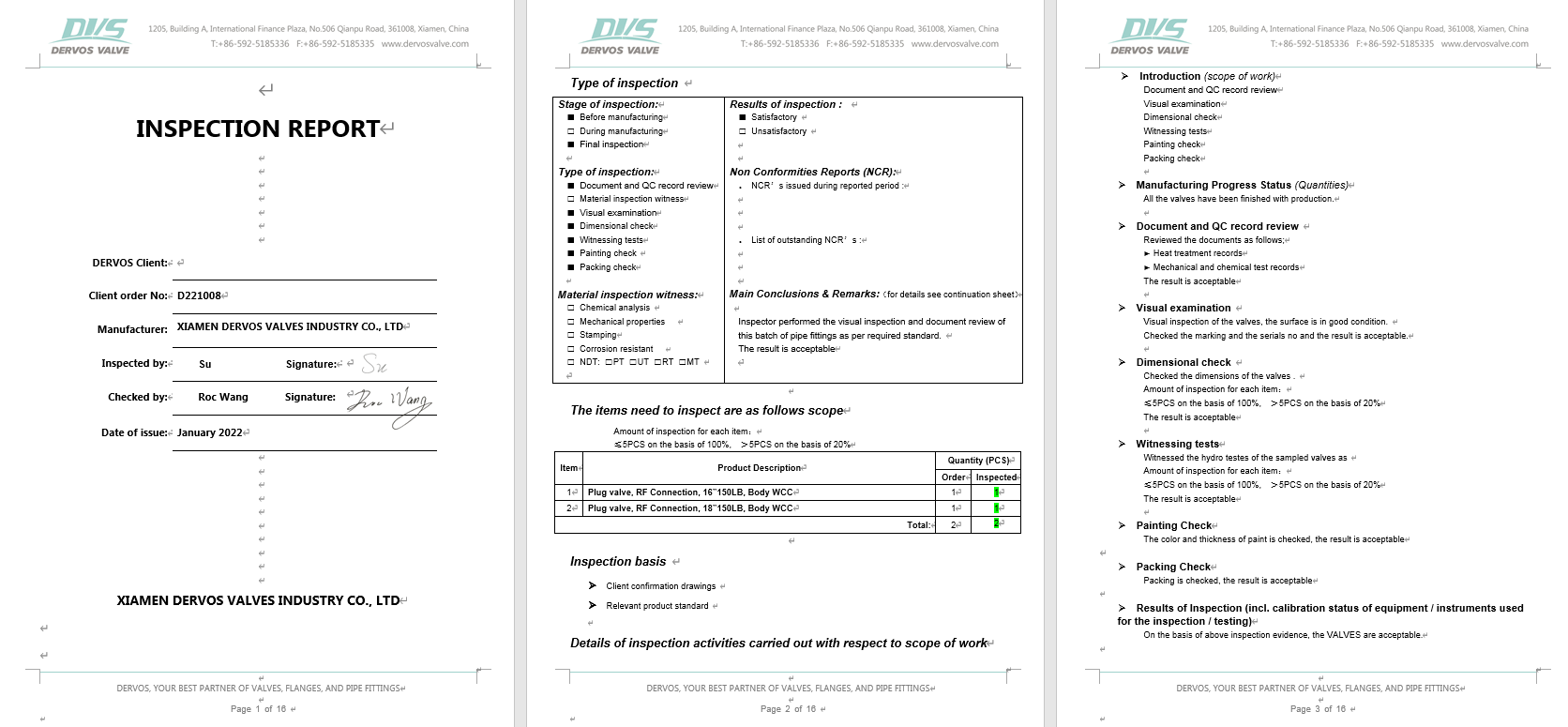

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.