Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaShipping Port:

Shanghai ChinaLead Time:

35~60 days Ex Works After Order ConfirmationMaterial:

Carbon Steel Ball Valve ASTM A105NMethod of Operation:

Bare Stem Ball ValveQuick Detail

|

Type |

Ball Valve |

|

Size |

20" |

|

Pressure |

ANSI 600 |

|

Construction |

Trunnion Type, One-Piece Body, Fully Welded, Metal to Metal Seat |

|

Connection |

Flanged |

|

Operation |

Bare Stem |

|

Body Material |

Forged Steel ASTM A105 |

|

Design Standard |

API 6D |

|

Pressure & Temp |

ASME B16.34 |

|

Face to Face Dimension |

ASME B16.10 |

|

End Connection |

ASME B16.5 |

|

Inspection |

API 598 |

|

Temperature Range |

-29℃~+200℃ |

|

Media |

Oil, Water, Gas |

Dimension

| CLASS 600 | |||||||||||||

| DN | mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

| NPS | in | 2 | 2.5 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

|

L (RF) |

mm | 292 | 330 | 356 | 432 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 |

| in | 11.5 | 13 | 14 | 17 | 22 | 26 | 31 | 33 | 35 | 39 | 43 | 47 | |

|

L1 (BW) |

mm | 292 | 330 | 358 | 432 | 22 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 |

| in | 11.5 | 13 | 14 | 17 | 559 | 26 | 31 | 33 | 35 | 39 | 43 | 47 | |

|

L2 (RTJ) |

mm | 295 | 333 | 359 | 435 | 562 | 664 | 791 | 841 | 892 | 994 | 1095 | 1200 |

| in | 11.63 | 13.13 | 14.13 | 17.13 | 22.13 | 26.13 | 31.13 | 33.13 | 35 | 39.5 | 43.1 | 47.3 | |

| H | mm | 153 | 165 | 195 | 213 | 272 | 342 | 495 | 580 | 630 | 725 | 800 | 850 |

| in | 6.02 | 6.5 | 7.68 | 8.39 | 10.7 | 13.5 | 19.5 | 22.85 | 24.8 | 28.5 | 31.5 | 33.5 | |

| Do(W) | mm | 600 | 850 | 1250 | 1300 | 1500 | *350 | *350 | *600 | *600 | *800 | *800 | *800 |

| in | 23.62 | 33.46 | 49.25 | 51.22 | 59 | 13.8 | 13.8 | 23.6 | 23.6 | 31.5 | 31.5 | 31.5 | |

| RF(Kg) | 38 | 56 | 66 | 122 | 217 | 350 | 660 | 820 | 830 | 1160 | 1420 | 1650 | |

| BW(Kg) | 31 | 51 | 58 | 117 | 200 | 327 | 605 | 790 | 800 | 1030 | 1305 | 1505 | |

| *Worm Gear or Electric actuator operated | |||||||||||||

Related Knowledge

When to use metal seated ball valve?

The seat of a metal seated ball valve is often stellite, stainless steel, or tungsten carbide instead of soft seat material like ptfe, peek, nylon, teflon, and devlon. These metal to metal seat ball valves are especially applicable for:

-Media with high temperature

-Media with solid particulate for high abrasion

-Media with severe condition, like high erosion and corrosion

-Media with high viscosity like heavy oil

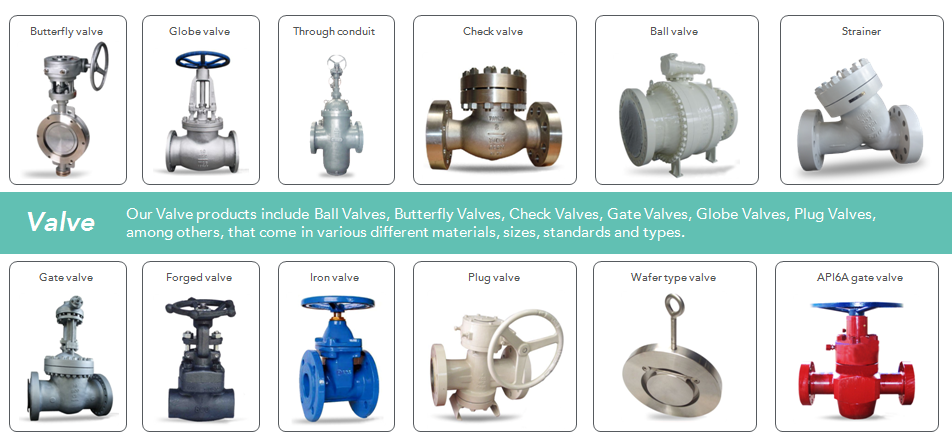

Our Main Product Range

Dervos main products include ball valves, butterfly valves, check valves, gate valves, globe valves, and plug valves in different materials, sizes, standards and types as per clients’ requests.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.