1" 600LB plug valve is made according to API 6D standard. The valve body is made of A216 WCB. It has the structural characteristics of inverted pressure balance lubricated and fire safe conform to API 6FA. Its connection mode is RF. And it has lever operation mode.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A216 WCBMethod of Operation:

LeverProduct Description

|

Type |

Plug Valve |

|

Size |

1" |

|

Pressure |

600LB |

|

Connection |

RF |

|

Operation |

Lever |

|

Body Material |

A216 WCB |

|

Design Norm |

API 6D |

|

Face to Face Dimension |

ANSI B16.10 |

|

Flange Dimension |

ANSI B16.5 |

|

Pressure-Temperature |

ASME B16.34 |

|

Fire Safe |

API 6FA |

|

Test & Inspection Code |

API 598 |

|

Temperature |

≤80°C |

|

Applicable Medium |

Water, Oil and Gas |

Features

1. The valve is equipped with a pressure balancing mechanism, which can maintain stable operation under high-pressure conditions, reduce opening and closing torque, and extend the service life of the valve;

2. Adopting oil sealing technology, lubricating oil is injected to form an oil film on the sealing surface, enhancing sealing performance, reducing wear, prolonging valve life, and preventing medium leakage.

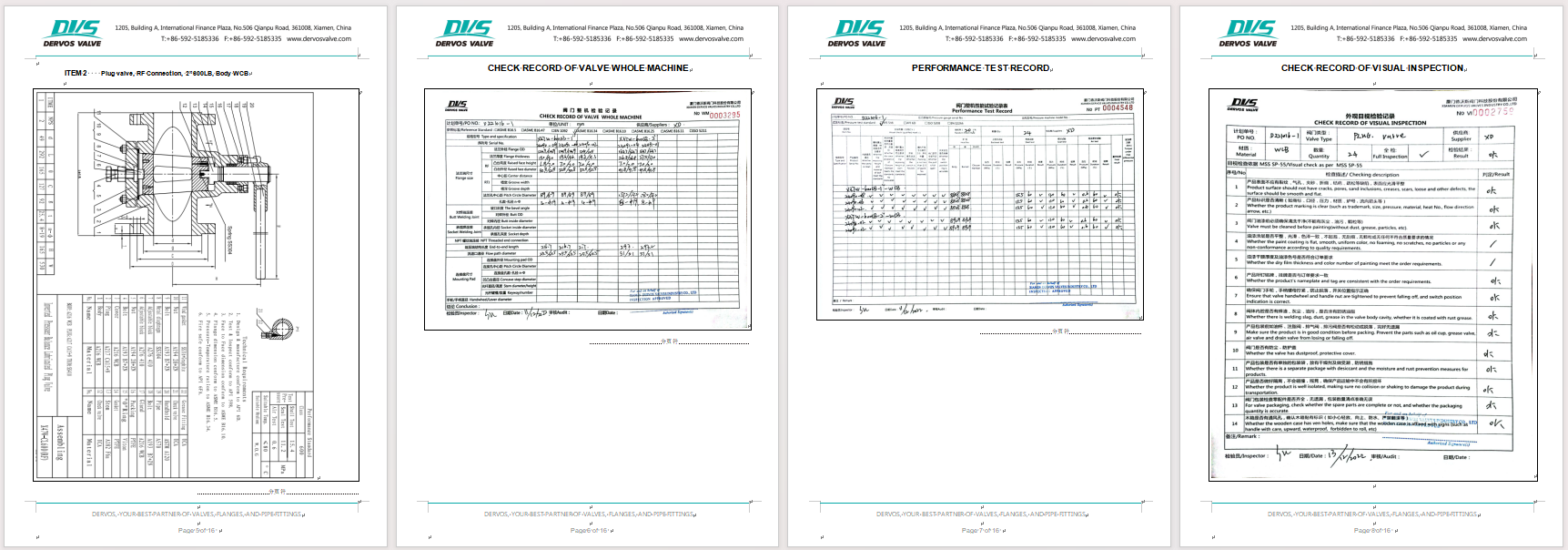

Technical Drawing

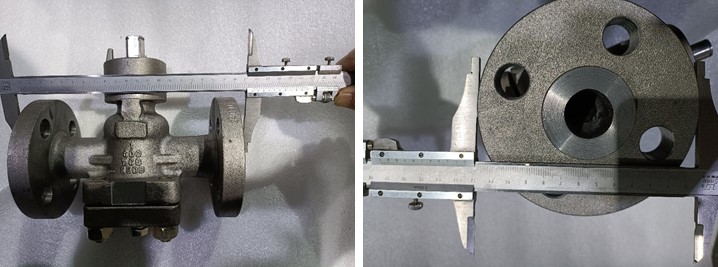

Dimension Checking

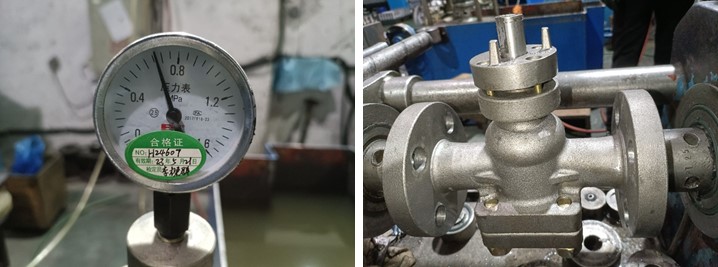

Pressure Testing

Nameplate & Packing

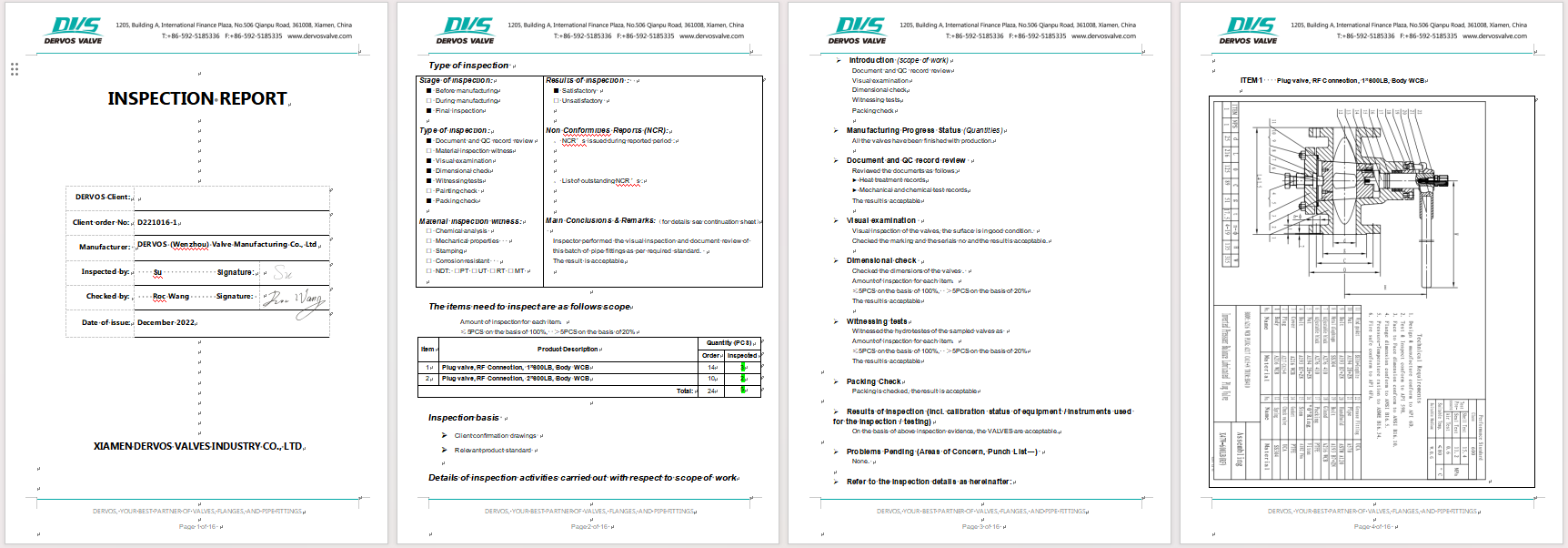

Inspection report

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.