Payment:

30% T/T When Order, 70% T/T Before ShipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai ChinaLead Time:

35~60 days Ex Works After Order ConfirmationMaterial:

Forged Steel Globe Valve, Carbon Steel Globe ValveMethod of Operation:

Handwheel Operated Globe Valve

Design Feature

1.Outside screw and yoke

2.Rising stem

3.Bolted bonnet design

4.Bellow seal packing for reliable stem sealing

5.Reduced bore design

6.Handwheel Operated

Quick Detail

|

Type |

Globe Valve |

|

Size |

1.5'' |

|

Design Pressure |

Class 800 |

|

Structure |

BB, OS&Y, Reduced Port, Bellow Seal Packing |

|

Connection Type |

Socket Weld |

|

Operation |

Handwheel |

|

Design Code |

API 602 |

|

End to End |

ASME B16.10 |

|

Connection End |

ASME B16.11 |

|

Pressure & Temperature |

ASME B16.34 |

|

Test & Inspection Standard |

API 598 |

|

Body Material |

Forged Steel ASTM A105 |

|

Trim Material |

Trim 8 |

|

Applicable Temperature |

-29℃~+425℃ |

|

Application |

W.O.G |

|

Origin |

China |

Related Knowledge

What is a bellw seal valve?

For bellow seal globe valves, the lower end bellows is welded on the valve stem to prevent the process fluid from eroding the valve stem. The other end is placed between the valve body and the valve cover to form a static seal. The double seal design ensure that if bellow seal pakcing fails, the stem packing will also function.

The bellow seal globe valves are applicable for media like steam, flammable, explosive, heat transfer oil, high purity, and toxic media etc.

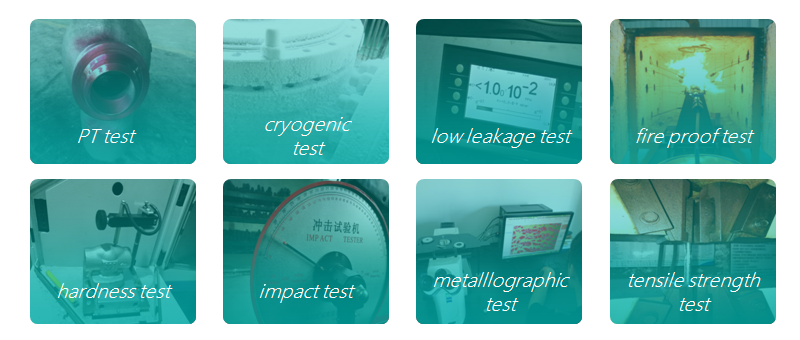

Special Tests

Besides general tests we will do (hydraulic and air test), we could also do tensile strength test, metallographic test, fugitive emission test, and NDE test (UT,RT,PT,MT) upon customers’ specific requests.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.