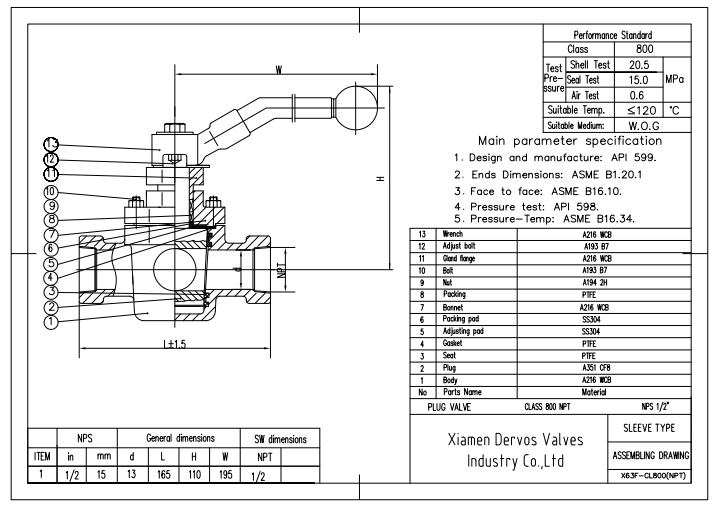

This 1/2 Inch plug valve is made of A216 WCB, according to API598.With little required maintenance and trouble-free operation, a high integrity bubble-tight seal is provided both in-line and to atmosphere.

Payment:

30% when order confirmed, 70% before shipmentProduct Origin:

ChinaColor:

CustomizationShipping Port:

Shanghai, ChinaLead Time:

30~60 days Ex Works after order confirmationMaterial:

A216 WCBMethod of Operation:

WrenchQuick Detail

|

Type |

Plug Valve |

|

Nominal Diameter |

1/2 Inch |

|

NominalPressure |

800LB |

|

Construction |

Sleeve Type |

|

Connection |

NPT |

|

Design & Manufacture |

API599 |

|

Ends End Dimension |

ASME B1.20.1 |

|

F to F Dimension |

ASME B16.10 |

|

Pressure Test |

API598 |

|

Body Material |

A216 WCB |

|

Plug Material |

A315 CF8 |

|

Temp. Range |

≤120°C |

|

Media |

Water, Oil, Gas, etc |

Features

-Free of cavities

-Maintenance free – self lubricating

-Easy accessible adjustment of the plug, even with mounted actuator

-Bi-directional in-line bubble-tight seal independent of line pressure

-Multiple external bubble-tight seals independent of line pressure

-Positive flow direction indication

Technical Drawing

Witness Tests

Packing

DVS Purchasing System

Dervos purchasing system plays an important role in order follow up and supplier management.

What does our purchasing team do?

-Confirm production plan with the factory

-Follow up the order according to the production plan very closely

-Take every measure to initiate all related resources to solve the delay crisis

-Seek new suppliers and put them into our supplier pool by evaluating them onquality, equipment, certificates, price level, technical supports etc

-Do annual evaluation on current suppliers and eliminate those unqualified ones.

All these actions will make sure that clients’ order will be delivered on time and we can find most suitable products among qualified suppliers in an efficient way.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.